- Why Predictive Quality Matters in 2025

- What Is Predictive Quality?

- Why Traditional Quality Control Isn’t Enough

- How AI-Driven Predictive Quality Works

- Key Technologies Behind Predictive Quality

- Predictive Quality in Action – Industry Case Studies

- Benefits of Predictive Quality

- Challenges & Barriers

- From Predictive to Prescriptive Quality

- How to Get Started with Predictive Quality

- Future Trends in Predictive Quality

- Case Studies & Real-World Examples

- FAQ (Frequently Asked Questions)

- Final Call-to-Action (CTA)

Why Predictive Quality Matters in 2025

If you’ve been in manufacturing long enough, you know this truth: quality issues are expensive. Every defective product means wasted raw material, wasted labor hours, rework costs, delayed shipments, and worst of all an unhappy customer who may never come back.

Now, here’s the kicker: in 2025, manufacturers don’t have the luxury of trial-and-error anymore. Global competition is brutal, customers expect faster delivery, and supply chain disruptions are still hitting the industry hard. If your plant is still relying on reactive quality control waiting until defects happen before taking action you’re already bleeding money.

This is where predictive quality changes the game. Instead of catching problems after they happen, predictive quality uses AI and advanced analytics to anticipate defects before they occur. It’s like having a superpower in your production line one that tells you where the next failure point will be and how to fix it in real time.

Think about it:

- Instead of scrapping a whole batch, you detect process drifts early.

- Instead of constant firefighting, your engineers can focus on optimization.

- Instead of endless customer complaints, you deliver consistent quality every time.

A recent Deloitte study even showed that manufacturers adopting predictive quality approaches can reduce defect rates by up to 30% while saving millions annually in waste reduction and downtime. That’s not theory it’s happening right now across automotive, electronics, pharmaceuticals, and even food processing.

Here’s why predictive quality is becoming non-negotiable in 2025:

- Speed of Production – With shorter product lifecycles, you can’t afford lengthy trial runs. Predictive insights shorten time-to-market.

- Data is Everywhere – Sensors, IoT devices, and cloud platforms make it easier than ever to capture process data. The challenge is turning that data into action.

- Customer Expectations – Tolerance for poor quality is zero. One viral complaint on social media can destroy years of brand building.

- Regulatory Pressure – Industries like pharma and aerospace can’t risk quality lapses. Predictive systems help ensure compliance proactively.

The bottom line? Predictive quality isn’t just another buzzword. It’s survival. The companies that embrace it will lead their markets. The ones that ignore it will keep wasting money, losing customers, and eventually losing relevance.

So, if you’re serious about staying competitive in 2025 and beyond, it’s time to stop asking, “Should we adopt predictive quality?” and start asking, “How fast can we get started?”

What Is Predictive Quality?

Let’s cut the jargon and make it simple: Predictive Quality is about using data and AI to predict defects before they happen. Instead of waiting for a bad batch or customer complaints, you’re spotting signals in your process tiny shifts, patterns, or anomalies that tell you, “Hey, this product might fail if you don’t adjust now.”

Sounds a lot like predictive maintenance, right? Close, but not the same thing. Here’s the difference you need to remember:

- Predictive Maintenance = keeping your machines healthy.

- Predictive Quality = keeping your products flawless.

👉 If maintenance is about preventing downtime, predictive quality is about preventing defects. One protects your equipment, the other protects your reputation.

To make it clearer, let’s look at the comparison side by side:

| Aspect | Predictive Maintenance | Predictive Quality |

|---|---|---|

| Focus | Equipment health | Product quality |

| Goal | Prevent downtime | Prevent defects |

| Data | Vibration, temperature | Vision, process, sensors |

See the shift? Maintenance data cares about whether your machine is about to fail. Quality data digs deeper: it checks if the output the product meets your standards.

The Core Ingredients of Predictive Quality

So, how does this actually work? It’s not magic. It’s a mix of three key components:

- Data Sensors – Cameras, IoT sensors, and even process logs capture real-time conditions in production.

- Machine Learning Models – Algorithms analyze historical and live data, spotting correlations humans might miss. For example, a slight temperature drift may lead to micro-cracks in plastics.

- Real-Time Analytics – Dashboards and alerts help engineers act before a defect spreads across the whole line.

Think of it like a factory’s nervous system. Sensors are the eyes and ears, machine learning is the brain, and real-time analytics is the reflex action that tells you when to intervene.

Why This Matters

By distinguishing predictive quality from predictive maintenance, you stop treating quality as an afterthought. You start seeing it as a proactive business advantage. Because at the end of the day, equipment uptime means nothing if what comes out of the machine is junk.

Why Traditional Quality Control Isn’t Enough

Here’s the uncomfortable truth: traditional quality control (QC) is broken. It was designed for a slower world, where production volumes were lower and defects didn’t spread like wildfire across global supply chains. In 2025, it’s simply not keeping up.

The Problems with Old-School QC

Let’s break it down:

- Manual QC is slow and expensive

Inspectors, checklists, and clipboards might feel “safe,” but they’re reactive. By the time a defect is spotted, it’s already cost you wasted materials, production delays, and sometimes even brand reputation. - Sampling is a gamble

Traditional QC doesn’t check every product. It samples. Which means if one defect slips through, it could multiply across thousands of units. Imagine one tiny crack missed in a semiconductor wafer—suddenly, you’re talking about millions of dollars in lost yield. - High-volume industries can’t afford errors

Think automotive, semiconductors, and pharmaceuticals. These aren’t industries where you can shrug and say, “Oops, a few bad products got out.” In automotive, just a 1% defect rate can translate into billions in warranty claims, recalls, and lost customer trust.

Reactive vs. Proactive

Traditional QC is like playing defense after the goal has already been scored. You react once the defect exists. Predictive quality flips that around. It says: “What if we could see the defect forming before it’s visible?” That shift from reactive to proactive changes everything.

The Business Reality

Let’s be blunt: companies that still rely purely on manual QC are bleeding money. The hidden costs include:

- Scrap & rework → entire batches trashed because the issue was found too late.

- Downtime → production lines stopped for investigation.

- Warranty & recall costs → expensive fixes and reputational damage.

- Regulatory risk → in pharma or food, even a small defect can trigger fines or shutdowns.

In today’s hyper-competitive markets, traditional QC isn’t just inefficient it’s dangerous.

That’s why more manufacturers are turning to AI-driven predictive quality. It’s not about replacing inspectors; it’s about giving them superpowers. Machines don’t get tired, don’t blink, and can detect micro-cracks invisible to the human eye.

👉 Bottom line: Traditional QC was good enough for the 20th century. But in 2025, it’s a liability.

How AI-Driven Predictive Quality Works

If traditional quality control is broken, then how does predictive quality actually fix it? The answer is simple: AI doesn’t just “check” products, it learns from them.

Let’s walk through the pipeline step by step, so you can see how manufacturers are already using it on their shop floors.

Sensors and Vision Systems – The Eyes of Predictive Quality

It all starts with data. IoT sensors measure process variables like pressure, temperature, and flow. At the same time, high-resolution cameras powered by computer vision inspect products for defects. Unlike human inspectors, these systems don’t blink, get tired, or miss micro-cracks.

👉 Example: An AI vision system can detect a hairline crack in an automotive body panel that no human eye could spot consistently.

Data Collection – From the Factory to the Cloud (or Edge)

Once captured, the data flows into storage-either in the cloud for heavy analytics or directly at the edge for instant decision-making. This is critical because in high-speed production (think semiconductor wafers or beverage bottling), you don’t have time to wait for central processing.

Machine Learning – Turning Data into Predictions

Here’s where the magic happens. Machine learning models analyze patterns in the data to predict when and where defects are likely to occur. Over time, the system gets smarter: the more data it sees, the better it predicts.

It’s not just about saying “this product has a defect”; it’s about predicting “this machine setting will likely create a defect if not corrected in the next hour.”

Dashboards and Alerts – Actionable Intelligence

The final step is where predictive quality adds business value. Dashboards give production managers real-time insights into defect risks. Instead of reacting after the damage is done, operators get an early warning system.

Alerts can even recommend corrective actions automatically: adjust temperature, tweak pressure, or recalibrate a vision system.

The Big Picture – A Crystal Ball for Quality

Think of predictive quality as your “quality crystal ball.” Instead of gambling with random sampling, you get visibility into every product, every process, in real time.

The result? Fewer defects, lower costs, and a competitive edge.

Key Technologies Behind Predictive Quality

If you think predictive quality is just another buzzword, think again. Behind the flashy term lies a powerhouse of technologies working together to catch defects before they even happen. Let’s break down the five pillars that make predictive quality not just possible-but a game-changer.

AI & Machine Learning → Pattern Recognition at Scale

Traditional QC teams can only analyze what they see in front of them. AI and machine learning, on the other hand, thrive on historical and live data. They’re like the Sherlock Holmes of your production line-spotting hidden correlations between process variables and defects that humans would completely miss. For example, a machine learning model might detect that when oven temperature drifts just 2°C higher than usual, there’s a 15% higher chance of product cracking. That’s insight no manual QC could ever deliver.

Computer Vision → Seeing What Humans Can’t

Let’s be honest: human inspectors get tired. Cameras don’t. And when combined with AI vision models, cameras can spot micro-cracks, scratches, or color inconsistencies that are invisible to the naked eye. In automotive manufacturing, computer vision systems can scan thousands of body panels per hour and flag defects in milliseconds. Imagine reducing recall risks by catching issues at the paint line instead of waiting for customers to complain.

Digital Twins → Simulating Quality Before Mass Production

Here’s where things get futuristic. A digital twin is a virtual replica of your production process. By feeding it real-world data, you can simulate “what-if” scenarios and predict quality outcomes before running actual batches. Semiconductor companies are using digital twins to test hundreds of process variations in silico, so when the real production starts, the defect rate drops dramatically. Think of it as rehearsal for your factory-without the wasted materials.

Edge AI → Real-Time Decisions at the Source

Predictive quality doesn’t just live in the cloud. With edge AI, intelligence moves directly onto the production floor-embedded in cameras, sensors, or even robotic arms. That means decisions happen instantly, not after data travels halfway across the internet. A food and beverage plant, for instance, can adjust ingredient mixing ratios in real time if viscosity sensors show early signs of inconsistency. The result? Consistent taste, zero waste, and happy customers.

Big Data Analytics → Connecting the Dots

Data by itself is useless. But when you apply big data analytics, you connect process parameters, environmental conditions, and operator inputs into one holistic view of quality. Suddenly, you’re not just spotting defects-you’re uncovering the root causes. Pharmaceutical companies leverage this to identify which batch conditions lead to formulation instability, preventing million-dollar losses from recalls.

Bottom line: These five technologies don’t work in silos. They form an ecosystem that makes predictive quality the “crystal ball” every manufacturer wished they had. The faster you embrace them, the quicker you move from reactive firefighting to proactive excellence.

Predictive Quality in Action – Industry Case Studies

When we talk about predictive quality, it’s easy to think of it as just another buzzword. But the reality is this: companies across industries are already using it to save millions, reduce waste, and speed up production cycles. Let’s break down some real-world examples where predictive quality is making a tangible difference.

Read More: AI-Driven Predictive Quality Control in Manufacturing: Cut Waste, Improve Output

Automotive – Zero Defect Mindset

In the automotive sector, even the smallest defect can trigger a massive recall. Imagine a micro-crack in a body panel that escapes manual inspection. That single flaw could end up costing millions in warranty claims. Today, automakers are deploying AI-powered vision systems that scan every panel in real time. These systems catch defects invisible to the human eye, reducing recalls and saving both money and brand reputation. One leading OEM reported saving over $15 million annually simply by reducing their defect rate by 1%.

Pharma – Predicting Batch Failures Before They Happen

Pharmaceutical manufacturing is unforgiving: if one batch fails quality checks, the financial loss can skyrocket into tens of millions. By analyzing IoT sensor data – from temperature fluctuations to humidity levels – predictive AI can forecast potential failures hours or even days before final testing. That means manufacturers can stop or adjust production proactively, instead of throwing away an entire batch. In one case study, a top pharma company cut batch failures by 30%, translating into savings of $25 million per year.

Food & Beverage – Consistency is King

For food and beverage companies, the challenge isn’t just safety – it’s consistency. No customer wants a soda that tastes “slightly off” from one bottle to the next. IoT sensors combined with predictive algorithms monitor variables like sugar concentration, carbonation, and microbial safety in real time. This allows factories to adjust processes instantly, guaranteeing taste and safety across millions of units. Beyond quality, companies have reported yield improvements of 5–8%, which, in high-volume production, equates to millions of dollars saved annually.

Semiconductor – Managing Extreme Complexity

Semiconductor plants deal with hundreds of process parameters for each wafer. A tiny variation can cut yield and delay production. By applying predictive AI, fabs can model and anticipate how different variables interact, pinpointing issues before they cause defects. For example, adjusting gas flow or temperature at just the right moment can boost yield by 5–10%. In an industry where every extra wafer is worth thousands, that’s a competitive edge no company can ignore.

Bottom Line: ROI You Can’t Ignore

Across industries, predictive quality isn’t just a “nice-to-have.” It’s a profit driver. Whether it’s an automaker saving $10M+ a year, a pharma giant preventing multimillion-dollar batch losses, or a food company improving yield by 7%, the ROI is crystal clear. Companies adopting predictive quality are reporting returns between 5x and 10x on their AI investments.

Benefits of Predictive Quality

Let’s be real: the only reason manufacturers invest in new technology is because it saves money, makes processes faster, or gives them a competitive edge. Predictive quality does all three – and then some.

Reduce Defects → Direct Cost Savings

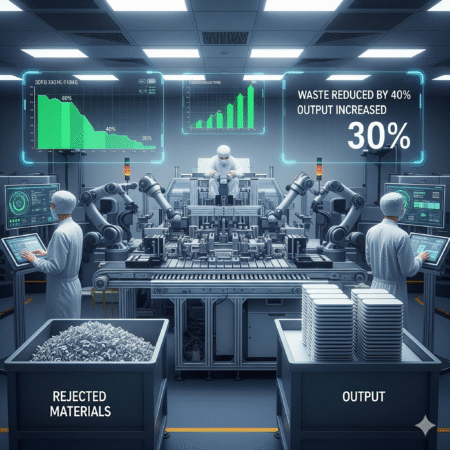

Traditional QC methods are reactive. By the time you discover a defect, it’s already too late. Predictive quality flips that script. Instead of catching problems after they occur, AI flags potential issues in real time. Manufacturers report defect reductions of 30–40%, which directly translates into millions saved annually. Think about it: every defective product you prevent is money that never leaves your pocket.

Improve Yield & Throughput

When predictive quality identifies the root causes of variation, production teams can fine-tune processes before problems escalate. For example, a semiconductor plant using AI-driven yield prediction improved output by 7% – an increase worth hundreds of millions in additional revenue. In industries where margins are razor thin, even a 2–3% improvement in yield is a game-changer.

Faster Time-to-Market

In fast-moving markets, speed is everything. Predictive quality reduces rework, shortens testing cycles, and minimizes downtime. That means new products hit the shelves faster. One automotive supplier cut their product launch timeline by 20% simply by embedding AI into their quality pipeline. Faster launches don’t just mean more sales – they also strengthen market positioning against competitors.

Compliance & Safety Made Simple

Every manufacturer dreads audits. But predictive quality makes compliance almost effortless. With AI and IoT sensors continuously monitoring and recording process data, you have a digital audit trail ready at all times. This not only helps with regulatory requirements but also boosts trust with customers. In pharma, where compliance can make or break a company, predictive systems ensure batch consistency and safety, reducing the risk of costly recalls.

Gaining a Competitive Advantage

Here’s the kicker: predictive quality isn’t just about saving money – it’s about staying ahead. Companies that adopt it early build a reputation for reliability and innovation. Customers notice. Partners notice. Investors notice. And while your competitors are stuck firefighting defects, you’re scaling production confidently with fewer surprises.

The Numbers Don’t Lie

A recent survey found that manufacturers adopting predictive quality reported:

- 30–40% fewer defects

- 5–10% higher yield

- Up to $10M/year in savings depending on industry scale

When you add all of this up, the ROI is undeniable. Predictive quality isn’t just another digital transformation buzzword – it’s the new standard for modern manufacturing.

Challenges & Barriers

Let’s be honest: predictive quality sounds amazing on paper – fewer defects, more yield, massive cost savings. But here’s the catch: making it work in the real world isn’t a walk in the park. Many manufacturers jump into AI-driven quality control only to hit roadblocks that slow them down. Understanding these barriers upfront is the first step to overcoming them.

High Upfront Investment (AI + IoT)

Implementing predictive quality isn’t just about buying new software. It often requires installing IoT sensors, high-resolution cameras, edge devices, and cloud infrastructure. For small and mid-sized manufacturers, the initial capital expense feels like climbing Mount Everest. A global survey showed that 60% of manufacturers hesitate to adopt AI quality tools due to budget constraints. The ROI is strong in the long run, but the upfront costs make CFOs nervous.

Data Silos & Legacy System Integration

Old manufacturing plants are full of legacy systems – PLCs, MES, and ERP platforms that don’t “talk” to each other. Predictive quality thrives on clean, centralized data pipelines, but when your information is scattered across silos, AI models can’t reach their full potential. Think of it like trying to stream Netflix with a dial-up connection – frustrating and ineffective. Integration with legacy systems is often one of the most time-consuming challenges.

Cultural Resistance from Traditional QC Teams

Change is hard. Many quality control teams are comfortable with manual inspections or sampling-based methods. To them, AI can feel like a threat: “Will this replace my job?” or “How can I trust a machine over my own eyes?” This cultural pushback slows adoption. Successful companies tackle this by reframing AI as a collaborator, not a replacement – giving teams better tools to focus on root-cause analysis instead of repetitive tasks.

Talent Shortage (Data Scientists + Quality Engineers)

Predictive quality sits at the intersection of data science and manufacturing expertise. You need people who can not only build machine learning models but also understand why a small vibration in a motor might affect product yield. This kind of hybrid talent is rare – and expensive. Companies that fail to invest in training or partnerships with AI vendors often get stuck halfway through implementation.

Trust & the Risk of False Positives/Negatives

What happens if the AI flags a “defect” that isn’t really there (false positive) or misses a real issue (false negative)? Both scenarios cost money and erode trust. Building trust in AI predictions takes time, testing, and transparency. Manufacturers need explainable AI – systems that show why a defect was predicted, not just a black-box alert.

Bottom Line

The barriers are real: money, systems, people, and trust. But here’s the good news – every company that successfully implemented predictive quality faced these same challenges. The winners weren’t those with unlimited budgets, but those who started small, proved ROI fast, and scaled gradually.

From Predictive to Prescriptive Quality

If predictive quality is about knowing what’s likely to go wrong, then prescriptive quality takes it one step further: it tells you exactly what to do about it. Think of predictive analytics as your GPS saying, “There’s traffic ahead.” Useful, right? But prescriptive analytics is when the GPS goes further: “Take a left in 200 meters, you’ll save 20 minutes.” That’s the real game-changer.

In manufacturing, prescriptive quality doesn’t just predict a defect – it recommends corrective action in real time. Instead of waiting for a batch to fail, the system might say:

- “Adjust the oven temperature by 2°C to prevent cracking.”

- “Reduce machine vibration by tightening spindle alignment.”

- “Swap out raw material Lot #42, it shows signs of contamination.”

This shift transforms AI from a passive observer into an active decision-making partner. It’s the difference between spotting a fire and having a robot fireman extinguish it before you even smell smoke.

Why Prescriptive Quality Matters

Predictive quality is powerful, but it still leaves humans to decide the next step. And in high-volume industries – automotive, pharma, electronics – every second counts. Prescriptive systems eliminate hesitation by providing actionable, automated recommendations that keep production lines optimized.

Imagine this: an AI system detects that your packaging line will likely jam within the next 30 minutes due to belt tension. Predictive quality alerts you, but prescriptive quality goes further:

“Reduce conveyor speed by 5% and increase lubrication cycle now.”

That’s not just information, that’s prevention in action.

Closed-Loop Quality Control – The Future

The holy grail here is full closed-loop quality control. That means AI doesn’t just suggest actions – it actually executes them automatically without human intervention. For example, if the AI sees micro-cracks forming in semiconductor wafers, it could instantly tweak laser calibration to fix the process mid-stream. No delays. No scrap. Maximum yield.

This is where we’re heading: factories that continuously self-correct, where quality control isn’t a department but an autonomous nervous system running through the entire plant.

Real-World Example

A leading food & beverage company recently tested prescriptive AI to manage pasteurization. Instead of just predicting temperature drift, the AI automatically adjusted heating cycles to maintain optimal conditions. The result? 5% yield improvement and fewer recalls due to consistent product quality.

The Bottom Line

Predictive quality helps you see problems before they happen. Prescriptive quality helps you fix them instantly. And as manufacturers move toward Industry 4.0, those who master prescriptive quality will gain a massive competitive edge: faster output, near-zero defects, and smarter use of resources.

So the real question isn’t “Will you adopt predictive quality?” It’s “How fast can you move toward prescriptive quality before your competitors leave you behind?”

How to Get Started with Predictive Quality

Here’s the truth: implementing predictive quality isn’t about buying the most expensive AI system on the market. It’s about starting small, learning fast, and scaling what works. Too many manufacturers get stuck because they think, “We need a full factory-wide AI rollout.” That’s a recipe for delays and frustration. Instead, the winning strategy is to start lean and grow steadily.

Let’s break it down step by step.

Identify Critical Process Parameters

Don’t try to monitor everything. Start with the processes that have the biggest impact on yield or customer complaints. For example, if you’re in electronics, maybe soldering quality is your top pain point. In food manufacturing, maybe it’s temperature control during pasteurization. Zero in on the vital few, not the trivial many.

Install Sensors & Collect Data

Predictive quality lives and dies on data. Without reliable data, AI is just guessing. This is where IoT sensors come in: vibration sensors, temperature probes, cameras, pressure gauges. The goal isn’t to create a massive data lake overnight – it’s to gather consistent, high-quality data on those critical parameters you identified earlier.

Start a Pilot Project (One Production Line)

Here’s where most companies trip: they try to roll out AI plant-wide from day one. Don’t. Instead, launch a pilot on a single production line or machine. This keeps risks low, costs manageable, and results measurable. Within weeks, you’ll start seeing insights: which variables drive defects, where downtime hides, and what changes deliver quick wins.

Build and Iterate Your Machine Learning Model

AI models are like athletes – they don’t get good on day one. You need to train, test, and retrain them. Feed the model real-world data, compare predictions against outcomes, and fine-tune. Think of this stage as raising a child: the more you guide and correct, the smarter it becomes.

Scale Up Across the Plant

Once your pilot line consistently predicts and prevents quality issues, it’s time to scale. Expand sensors to other machines, replicate the AI model across lines, and integrate results into your broader quality management system. This is when predictive quality stops being an experiment and becomes a competitive advantage.

Pro Tips for Success

- Start small, think big: Your first pilot is a proof of concept, not the finish line.

- Iterate relentlessly: Expect your first model to be “good enough,” not perfect.

- Don’t underestimate culture: Train your operators and quality teams so they trust and use the system.

The takeaway? Predictive quality is a journey, not a one-off project. Start with one line, one process, and one clear goal. Nail it, then expand. Before you know it, you’ll have an entire plant that doesn’t just detect defects – it prevents them before they happen.

Future Trends in Predictive Quality

Here’s the exciting part: predictive quality today is just the beginning. We’re moving into a world where machines don’t just predict – they simulate, prescribe, and even self-correct. If you’re wondering what the future looks like, think of it as a shift from reactive firefighting to autonomous quality assurance.

Let’s unpack the big trends that will shape the next wave of predictive quality.

Digital Twins → Virtual Factories That Never Sleep

Imagine having a mirror image of your production line in the cloud. Every sensor, every parameter, every machine is replicated digitally. That’s what a digital twin does. Instead of waiting for defects to show up on the shop floor, you can test changes virtually. Want to know if adjusting oven temperature by 3°C reduces defects? Run it in the digital twin first. This saves time, money, and raw materials.

Companies like Siemens and GE are already pioneering this, and in the next 3–5 years, digital twins will be standard in high-volume manufacturing.

Cloud Manufacturing + Edge AI → Real-Time, Anywhere

Data is only powerful if it’s fast. With cloud and edge AI, quality decisions don’t get stuck waiting for analysis in a central server. Instead, AI runs directly at the machine level, analyzing sensor input in milliseconds and adjusting parameters on the fly.

Think about it: a bottling line can instantly detect a cap misalignment and auto-correct the filler head before defective bottles pile up. That’s not future talk – it’s already happening in pilot projects, and scale adoption is coming soon.

Prescriptive Quality → From Prediction to Action

Right now, predictive quality tells you: “This batch has a 70% chance of defect.” That’s good, but the future is prescriptive. AI won’t just predict – it’ll recommend specific corrective actions.

Example: Instead of saying “Defects likely,” your system will say, “Increase mixer speed by 5% for the next 30 minutes to avoid viscosity issues.” Even better? In fully autonomous plants, the AI won’t ask — it will adjust automatically.

AI + Human Collaboration → Augmented Operators

Don’t worry, AI isn’t replacing humans in quality – it’s augmenting them. Operators equipped with AR glasses could see real-time defect alerts, root cause analysis, and recommended fixes right in their field of vision. It’s like having a digital co-pilot for every worker on the floor.

Sustainability-Driven Quality

The pressure for greener manufacturing means predictive quality won’t just cut defects – it’ll minimize waste, energy use, and carbon footprint. Future AI models will track sustainability KPIs alongside quality metrics, making compliance with ESG goals easier and cheaper.

The Bottom Line: The future of predictive quality isn’t just about fewer defects – it’s about smart factories that think for themselves. From digital twins to prescriptive AI, the companies that invest now will set the gold standard for efficiency, safety, and sustainability.

Case Studies & Real-World Examples

It’s easy to talk theory, but what really matters is: does predictive quality work in the real world? The answer is a resounding yes. Let’s dive into some case studies that show how global manufacturers are already reaping the rewards.

Case Study 1: Automotive – Toyota’s Drive for Zero Defects

The automotive industry is ruthless when it comes to quality. A single defective part can trigger recalls worth millions. Toyota piloted predictive quality using IoT sensors on welding lines. By analyzing vibration and heat data, AI models detected weld inconsistencies hours before traditional QC checks would have caught them.

- Results: Defect rates dropped by 35%, downtime reduced by 20%, and warranty claims plummeted.

- Lesson Learned: Predictive quality isn’t just about fewer recalls – it strengthens customer trust and brand reputation.

Case Study 2: Food & Beverage – Nestlé’s Smart Factories

In food production, quality is also safety. Nestlé deployed predictive analytics across chocolate production lines, where consistency in texture and taste is non-negotiable. Sensors tracked temperature, humidity, and ingredient mixing. The AI flagged anomalies in real time and suggested corrections like adjusting mixer speed or extending cooling cycles.

- Results: Yield improved by 12%, waste reduced by 18%, and energy consumption dropped by 10%.

- Lesson Learned: Predictive quality boosts not just efficiency, but also sustainability goals – a double win.

Case Study 3: Electronics – Samsung’s Semiconductor Edge

Semiconductors are unforgiving: one microscopic defect can render an entire batch useless. Samsung integrated predictive quality powered by edge AI in its wafer production. By running advanced anomaly detection directly on machines, the system instantly flagged defect risks. Instead of scrapping batches, operators could adjust parameters mid-process.

- Results: Scrap reduced by 40%, and production cycle times shortened by 15%.

- Lesson Learned: When margins are razor-thin, predictive quality can make or break profitability.

Case Study 4: Oil & Gas – Shell’s Predictive Maintenance + Quality

Even in heavy industries like oil and gas, predictive quality is changing the game. Shell combined predictive maintenance with quality analytics on pipeline welding. The AI monitored sensor data during construction and flagged potential weak welds before they passed into service.

- Results: Safety compliance improved drastically, and rework costs shrank by millions annually.

- Lesson Learned: Predictive quality isn’t limited to fast-moving consumer goods – it scales across industries.

Takeaway: Whether it’s cars, chocolate, chips, or crude oil, predictive quality delivers measurable ROI. Companies report 30–40% fewer defects, 10–20% higher yield, and millions saved in waste reduction.

The proof is already here. The only question is: when will you get started?

FAQ (Frequently Asked Questions)

1. What exactly is Predictive Quality?

Predictive Quality is the use of AI, IoT sensors, and machine learning to detect and even prevent defects before they happen. Unlike traditional quality control that checks products after production, predictive quality monitors data in real time and alerts teams when processes are drifting out of spec.

2. How is it different from traditional Quality Control (QC)?

Traditional QC is reactive: you inspect, find defects, and then fix. Predictive Quality is proactive: you predict defects in advance and prevent them from happening. This shift saves money, time, and improves yield because problems are caught earlier in the process.

3. Is Predictive Quality expensive to implement?

Yes and no. The initial investment (sensors, IoT, AI models) can be significant, especially for large plants. But most companies see ROI within 12–24 months thanks to reduced defects, lower rework, and faster production. Think of it as an upfront cost that pays for itself quickly.

4. Which industries benefit the most?

Predictive Quality is highly valuable in:

- Automotive → prevent recalls.

- Pharma → reduce batch failures.

- Food & Beverage → ensure hygiene and taste consistency.

- Semiconductors/Electronics → improve yield in high-precision manufacturing.

- Oil & Gas → ensure safety and compliance.

Basically, any industry where defects are costly or dangerous will benefit.

5. Do I need a big data science team to start?

Not necessarily. Many solutions are available as plug-and-play platforms with built-in AI models. However, to scale predictive quality across multiple plants, you’ll need data scientists, quality engineers, and process experts working together.

6. How accurate are AI predictions?

No system is 100% perfect. Predictive models can sometimes produce false positives or negatives. But with proper training, data integration, and feedback loops, accuracy can reach 85–95%, which is already game-changing compared to manual inspection.

7. What’s the future of Predictive Quality?

The next step is Prescriptive Quality: not only predicting defects but also recommending or automatically applying fixes. Imagine an AI system that notices your oven temperature is drifting and automatically adjusts it by 2°C to keep yield consistent. The long-term vision? Full closed-loop quality control where human intervention is minimal.

👉 Bottom Line: Predictive Quality is no longer a buzzword – it’s already transforming global industries. If you’re still relying only on traditional QC, you’re leaving money (and efficiency) on the table. The question isn’t if you should adopt it, but when.

Final Call-to-Action (CTA)

If you’ve read this far, you already know one thing: Predictive Quality isn’t optional anymore – it’s the new standard for staying competitive.

📉 Manufacturers who wait risk falling behind with higher defect rates, wasted materials, and costly recalls.

📈 Those who act now gain a clear advantage: faster time-to-market, reduced costs, and happier customers.

👉 So here’s your next step:

- Start small. Pick one production line and pilot predictive quality today.

- Leverage existing tools. Many platforms integrate directly with your sensors and MES systems.

- Don’t wait. Every month you delay is more defects, more scrap, and more money lost.

🔗 Want to go deeper? Check out our other guides on AI in Manufacturing, Digital Twins, and Prescriptive Quality. Or, if you’re serious about implementing Predictive Quality in your plant, get in touch with our team of experts – we’ll help you design a roadmap tailored to your operations.

The future of manufacturing isn’t about fixing problems. It’s about preventing them before they ever exist. Predictive Quality makes that future possible today.