Introduction

Predictive maintenance (PdM) isn’t just a trend it’s a revolution. With the help of artificial intelligence (AI) and machine learning (ML), industries are stepping into a smarter era where unplanned downtime can be drastically reduced, and maintenance costs optimized. According to Aberdeen Group, unplanned downtime can cost manufacturers up to $260,000 per hour. That kind of hit can cripple operations.

The shift from reactive to predictive strategies is more than a technical upgrade it’s a competitive advantage. In this article, you’ll discover how AI/ML powers predictive maintenance, which industries are already winning with it, and how your business can follow suit. We’ll also dive into tools, implementation strategies, and expert insights to help you get started.

What is Predictive Maintenance (PdM)?

Imagine if you could see into the future of your machines know when a motor will fail, or when a compressor is showing early signs of wear. That’s the promise of predictive maintenance.

Unlike preventive maintenance, which relies on fixed schedules, PdM harnesses real-time sensor data and AI algorithms to predict failure before it happens. This means maintenance teams act only when needed, saving time, money, and equipment lifespan.

How AI/ML Supercharges PdM

Traditional PdM relies on rule-based logic. AI, however, detects subtle patterns and evolves with every new data point. The result? Sharper predictions and fewer surprises.

| Feature | Traditional PdM | AI/ML-Powered PdM |

|---|---|---|

| Data Handling | Rule-based | Pattern recognition |

| Flexibility | Limited | Adaptive |

| Scalability | Manual tuning | Learns from big data |

| Accuracy | Lower | Continuously improving |

How AI Algorithms Power Predictive Maintenance

AI/ML enables a range of intelligent functions in PdM systems:

- Anomaly Detection: Uses models like Isolation Forests and Autoencoders to learn what “normal” looks like flagging deviations before failure.

- Time Series Forecasting: Algorithms like LSTM (Long Short-Term Memory) predict future trends in sensor data.

- Classification Models: XGBoost and Random Forest help distinguish between faulty and healthy conditions.

- Clustering: Unsupervised methods like K-means reveal hidden relationships between variables.

Real-World Industry Use Cases

Oil & Gas – Compressor Monitoring

Challenge: Unexpected compressor failures compromise safety and production.

AI Solution: An LSTM model processes pressure and vibration data to spot anomalies.

Result: Downtime reduced by 40%, emergency repair costs slashed.

Manufacturing – CNC Machines

Challenge: Tool wear leads to poor product quality.

AI Solution: Acoustic sensors combined with edge AI detect tool wear in real time.

Result: Rework rates dropped by 35%, maintenance costs lowered by 20%.

Power Generation – Gas Turbines

Challenge: Sudden turbine failures threaten grid stability.

AI Solution: Ensemble models provide failure forecasts up to 10 days in advance.

Result: Maintenance becomes proactive, grid reliability improves.

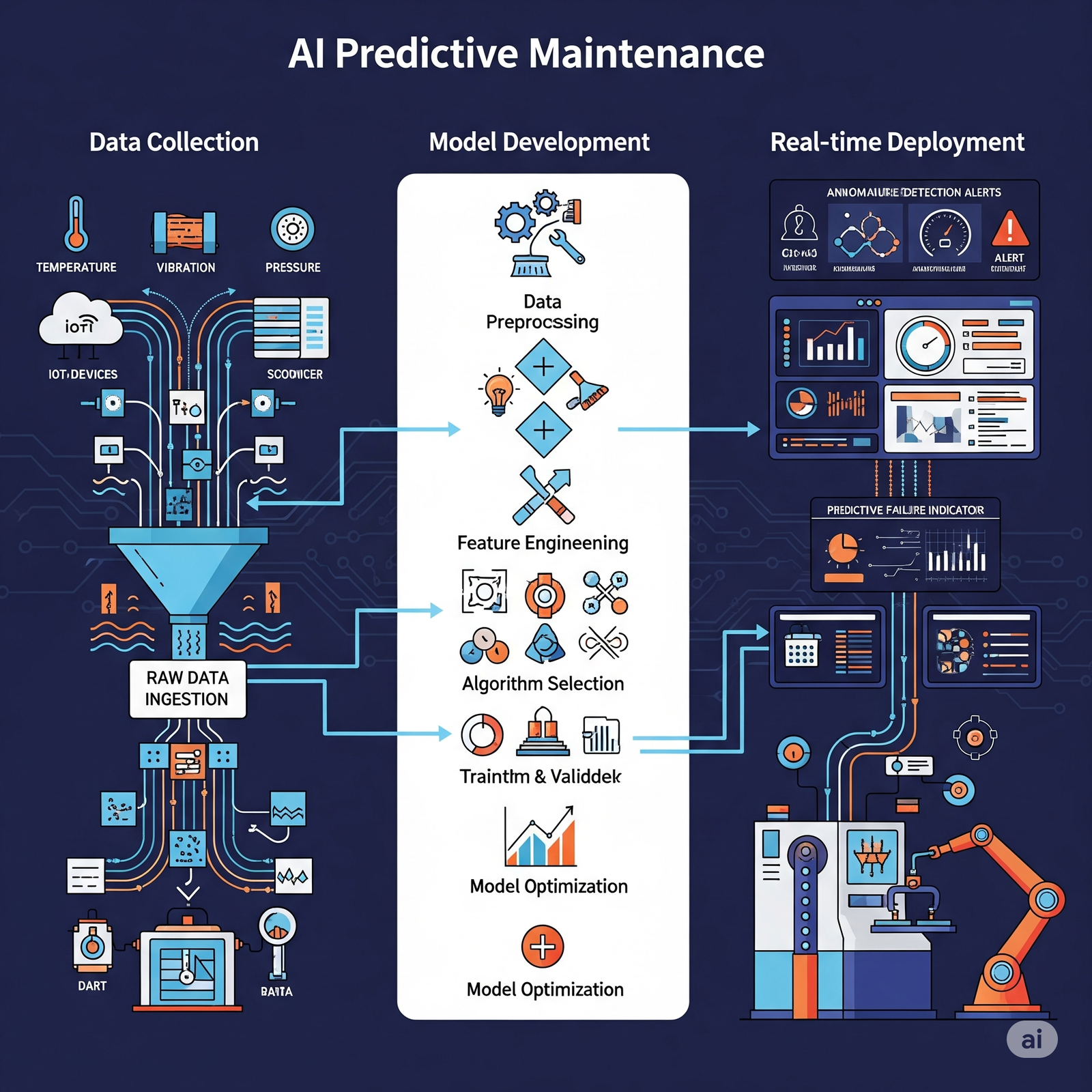

Building a Predictive Maintenance Pipeline

To implement PdM, follow this data-driven blueprint:

Step 1: Data Collection

- Key Parameters: Vibration, temperature, pressure, current

- Sources: PLCs, SCADA, DCS, IoT sensors

Step 2: Data Preprocessing

- Clean the Noise: Apply wavelet transforms

- Remove Outliers: Use Z-score or IQR methods

- Synchronize Data: Align multi-sensor time stamps

Step 3: Model Development

- Feature Engineering: Use FFTs, rolling statistics

- Algorithm Selection: LSTM for sequences, Random Forests for classification

Step 4: Deployment

- Edge Deployment: Use Advantech or Siemens devices for real-time scoring

- CMMS Integration: Feed predictions into Computerized Maintenance Management Systems

- Feedback Loop: Continuously retrain the model with new data

Challenges (And How to Beat Them)

Lack of Labeled Data

Failures are rare, which limits supervised learning. Solution? Use semi-supervised or unsupervised models and simulate failure scenarios for training.

Model Drift

Equipment behavior changes over time. Monitor performance and retrain models regularly to stay accurate.

Integration with Legacy Systems

Old systems don’t play well with new tech? Use middleware or IIoT platforms to bridge the gap.

Key Performance Metrics

| Metric | Purpose |

| Remaining Useful Life (RUL) | Estimate asset longevity |

| False Positives | Avoid unnecessary maintenance |

| Mean Time Between Failures | Measure reliability over time |

| Model Latency | Evaluate real-time responsiveness |

Tools and Platforms for PdM

Open-Source Tech Stack

- TensorFlow + Scikit-learn – For building ML models

- InfluxDB + Grafana – Time-series storage and visualization

Enterprise Solutions

- AWS Lookout for Equipment – Quick deployment with minimal setup

- Uptake, Seebo, SparkCognition – Purpose-built platforms with domain knowledge

Future Trends: What’s Next?

- Edge AI Growth: Faster decisions at the source

- Digital Twins: Real-time simulation for even better predictions

- Autonomous Maintenance: AI bots initiating repairs without human input

As these technologies mature, PdM will become smarter, faster, and more autonomous.

Final Thoughts

Predictive maintenance powered by AI/ML is democratizing industrial reliability. What was once only available to big players like GE is now accessible to mid-sized factories and startups.

This is not about replacing engineers it’s about empowering them. With the right data, models, and tools, your team can prevent failures before they happen.

If you’re serious about reducing downtime and improving asset performance, now is the time to adopt predictive maintenance.

👉 Subscribe to EngineerDaily.News for expert tutorials, implementation guides, and real-world insights in industrial AI/ML.

Got a question or use case to share? Drop it in the comments. Let’s engineer a smarter future together.