- The Hydrogen Gold Rush

- The Market Momentum Behind Hydrogen

- How Green Hydrogen Works (and Why It Matters)

- Industrial Use Cases Already Scaling

- Cost Curves Are Crashing: The Economics

- Infrastructure Challenges (Pipelines, Storage, Transport)

- Policy and Regulation Landscape

- Environmental & Safety Concerns

- Top Industry Players & Their Bets

- The Road to 2030: Forecasts & Scenarios

- Conclusion + CTA

The Hydrogen Gold Rush

Imagine standing at the edge of a massive energy shift – one so big it could reshape the entire global economy. That’s exactly where we are with hydrogen.

For decades, oil and gas were the beating heart of industrial growth. They powered our steel mills, cement plants, refineries, and shipping fleets. But today, those same industries are under relentless pressure to decarbonize. Governments are rolling out net-zero laws. Investors are demanding ESG performance. Customers are asking for cleaner products. And fossil fuels? They’re becoming the villain of the story.

Here’s where hydrogen steps in as the unexpected hero.

Over the past three years, industrial giants have quietly started calling hydrogen “the new oil.” Why? Because hydrogen can do something solar panels and batteries can’t – power high-temperature, heavy-duty industrial processes that account for nearly 30% of global CO₂ emissions.

Let’s be real: industries like steelmaking or ammonia production will never run on rooftop solar. They need an energy-dense, clean-burning fuel. Green hydrogen – produced from renewable electricity through electrolysis – fits that role perfectly.

And investors know it. According to BloombergNEF, global hydrogen investment surged past $70 billion by mid-2025, with over 1,000 large-scale projects announced worldwide. Just to give you perspective, in 2020 that number was under $10 billion. That’s a 7x jump in five years.

This is not a buzzword trend – it’s an industrial arms race.

Major players like Shell, BP, and TotalEnergies are staking billion-dollar bets. Tech firms like Siemens Energy and ITM Power are racing to supply electrolyzers. Even shipping giants like Maersk are signing contracts for hydrogen-based fuels to power future fleets.

And the reason is simple: whoever cracks hydrogen first wins the future of industrial energy.

This “gold rush” moment feels eerily similar to the early 1900s oil boom – but this time, the fuel is clean, scalable, and future-proof. The countries and companies that move fastest could dominate the new energy economy for decades.

So if you’re an engineer, policymaker, or investor, here’s the bottom line:

Ignore hydrogen, and risk becoming irrelevant by 2030.

The Market Momentum Behind Hydrogen

The global hydrogen industry is no longer a distant dream – it’s accelerating at record speed. In just the past three years, hydrogen has gone from a niche clean-energy topic to a multi-billion-dollar race among the world’s biggest economies and energy giants.

Here’s how the momentum is building:

Global Hydrogen Market Size (2025-2030 Projections)

According to recent market forecasts, hydrogen is projected to grow from ~$200 billion in 2025 to over $500 billion by 2030, driven mainly by demand from heavy industries and transport sectors.

| Year | Estimated Market Size (USD) |

|---|---|

| 2025 | $200 billion |

| 2026 | $260 billion |

| 2027 | $330 billion |

| 2028 | $410 billion |

| 2029 | $460 billion |

| 2030 | $520+ billion |

Key growth drivers:

- Rising carbon pricing pushing companies to seek low-carbon alternatives

- Net-zero targets announced by 100+ countries

- Rapid cost decline of electrolyzers

Investment Trends from Energy Giants

Energy giants are pouring billions into green hydrogen:

- Shell announced large-scale electrolyzer projects in the Netherlands and Germany.

- BP is investing in the world’s largest green hydrogen hub in Western Australia.

- TotalEnergies has set a goal to produce 1 million tons of clean hydrogen annually by 2030.

This surge of corporate capital signals strong long-term confidence in the hydrogen economy.

Government Funding & Subsidies

Global governments are providing massive policy tailwinds:

| Region | Major Initiatives |

|---|---|

| 🇺🇸 US | $8B Hydrogen Hubs program (Infrastructure Law), $3/kg tax credits |

| 🇪🇺 EU | €5.2B IPCEI hydrogen projects, Carbon Border Adjustment Mechanism |

| 🇯🇵 Japan | ¥15T Green Transformation (GX) fund |

| 🇨🇳 China | Provincial subsidies + 50+ pilot hydrogen cities |

These incentives reduce risk, unlock private investment, and accelerate commercial deployment.

Hydrogen Projected Market Value by Region (US, EU, Asia)

| Region | 2025 (USD) | 2030 (USD) | CAGR (2025–2030) |

|---|---|---|---|

| United States | $60B | $170B | 23% |

| European Union | $70B | $180B | 21% |

| Asia-Pacific | $50B | $160B | 25% |

Bottom line: The race to dominate the hydrogen market is on – and it’s backed by trillions in capital, government support, and long-term corporate strategies.

How Green Hydrogen Works (and Why It Matters)

Green hydrogen is being hyped as the clean fuel of the future – but how does it actually work? And why is it so crucial for reaching net-zero? Let’s break it down simply.

Read More: Industrial Carbon Capture for Oil & Gas 2025: Costs, Tax Credits & Cluster Access in the US/EU/UK

Electrolysis Basics Explained Simply

- Green hydrogen is produced through a process called electrolysis – splitting water (H₂O) into hydrogen (H₂) and oxygen (O₂) using electricity.

- When that electricity comes from renewable sources like solar or wind, the resulting hydrogen is completely carbon-free.

- Think of it like charging a giant “hydrogen battery” using green energy, which can then power heavy industries, trucks, or even ships.

Grey vs Blue vs Green Hydrogen

| Type | Source | CO₂ Emissions | ||

|---|---|---|---|---|

| Grey | Natural gas (steam methane reforming) | High (~9–12 kg CO₂/kg H₂) | ||

| Blue | Natural gas + carbon capture (CCUS) | Medium (~1–3 kg CO₂/kg H₂) | ||

| Green | Renewable electricity + water | Zero emissions |

- Grey hydrogen is cheap but dirty.

- Blue hydrogen reduces emissions but still relies on fossil fuels.

- Green hydrogen is fully clean and the only long-term sustainable option.

Why Green Hydrogen Is the Only Path to Net Zero

- Hard-to-decarbonize sectors like steel, cement, chemicals, shipping, and aviation can’t easily run on batteries.

- Green hydrogen offers a way to replace fossil fuels in these industries with zero-carbon fuel.

- By 2050, experts project that green hydrogen could cut global CO₂ emissions by up to 20%, making it essential for hitting net-zero climate targets.

Diagram: Hydrogen Production Pathway Comparison

| Input | Grey | Blue | Green |

|---|---|---|---|

| Feedstock | Natural gas | Natural gas | Water |

| Electricity | Low | Medium | High (renewables) |

| CO₂ Capture | No | Yes | Not needed |

| Emissions | High | Medium | Zero |

Bottom line: Green hydrogen isn’t just another clean tech trend – it’s the only pathway that can fully decarbonize the industries we can’t electrify.

Industrial Use Cases Already Scaling

Green hydrogen isn’t just stuck in pilot labs anymore – it’s already powering real-world industrial projects at scale. Here’s how major sectors are starting to switch from fossil fuels to clean hydrogen.

Steel Production Using Green Hydrogen (H2-DRI)

- Traditionally, steel is made in blast furnaces that burn coal, which emits ~1.8 tons of CO₂ per ton of steel.

- With Hydrogen-based Direct Reduced Iron (H2-DRI), hydrogen replaces coal as the reducing agent.

- This process produces water vapor instead of CO₂, cutting emissions almost to zero.

- Companies like SSAB, ArcelorMittal, and Thyssenkrupp are building large-scale H2-DRI plants in Europe.

Why it matters: Steel contributes ~7–9% of global CO₂ emissions. Switching to green hydrogen is a game-changer.

Ammonia & Fertilizers

- Today, most ammonia is made using grey hydrogen from natural gas (Haber-Bosch process).

- By swapping in green hydrogen, ammonia production becomes carbon-free.

- Green ammonia can also serve as an energy carrier, easily shipped and converted back to hydrogen at destination.

Why it matters: Fertilizer production is one of the largest industrial consumers of hydrogen today – so cleaning it up has a massive impact.

Refining & Petrochemicals

- Refineries use huge amounts of hydrogen for hydrocracking and desulfurization.

- This hydrogen is currently grey (high-emission).

- Replacing it with green hydrogen can slash refinery CO₂ emissions without changing core infrastructure.

Why it matters: Refining is responsible for 2–3% of global CO₂ emissions – decarbonizing this sector is crucial for net-zero targets.

Table: Current Large-Scale Industrial Hydrogen Projects

| Project Name | Sector | Capacity (MW) | ||

|---|---|---|---|---|

| HYBRIT (SSAB) | Steel (H2-DRI) | 250 | ||

| H2 Green Steel | Steel (H2-DRI) | 700 | ||

| NEOM Green Hydrogen | Ammonia/Fertilizer | 2,000 | ||

| Shell Rheinland | Refining | 100 |

Bottom line: Green hydrogen isn’t some distant dream – it’s already reshaping how we produce the materials that build our world.

Cost Curves Are Crashing: The Economics

For decades, hydrogen has been labeled as “too expensive to scale.”

But 2025 marks a turning point – the cost of producing green hydrogen is falling faster than analysts predicted, and that’s flipping the entire energy equation.

Here’s what’s driving this cost crash – and why it matters for investors, policymakers, and heavy industries alike.

CAPEX and OPEX Are Dropping Fast

- Electrolyzer prices have plunged nearly 60% since 2020, thanks to mass production, improved efficiency, and lower material costs.

- Operational costs (OPEX) are falling too, driven by AI-driven predictive maintenance and cheaper renewable electricity.

- The learning rate effect is real: the more gigawatts installed, the cheaper every new megawatt gets.

Result: what used to cost $4-6/kg in 2020 is now sliding toward $1–2/kg by 2030, depending on location and power source.

LCOH Benchmarks Are Becoming Competitive

Levelized Cost of Hydrogen (LCOH) is the key metric to watch. It bundles all costs – CAPEX, OPEX, financing, lifetime output-into one number.

| Region | 2025 Avg LCOH ($/kg) | Projected 2030 LCOH ($/kg) |

|---|---|---|

| US | $3.00–3.50 | $1.00–1.50 |

| EU | $3.50–4.00 | $1.50–2.00 |

| Asia | $4.00–5.00 | $1.50–2.00 |

By 2030, green hydrogen will be cost-competitive with natural gas (on an energy-equivalent basis) in many regions.

Green H₂ vs Natural Gas Cost Trajectory

| Year | Green Hydrogen ($/kg) | Natural Gas ($/kg-eq) |

|---|---|---|

| 2020 | $5.00–6.00 | $1.50–2.00 |

| 2025 | $3.00–3.50 | $2.00–2.50 |

| 2030 | $1.00–2.00 | $2.00–2.50 |

Bottom line: once LCOH crosses the $2/kg threshold, industries like steel, cement, and shipping will have no economic reason not to switch.

At that point, adoption accelerates exponentially.

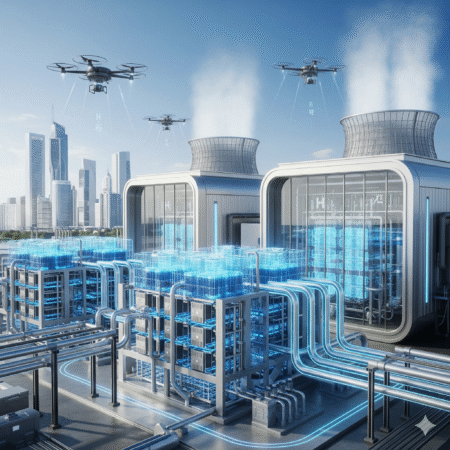

Infrastructure Challenges (Pipelines, Storage, Transport)

Green hydrogen might be the fuel of the future

but getting it from Point A to Point B is one of the biggest bottlenecks holding the industry back.

Let’s break down why moving hydrogen is hard, what infrastructure exists today, and where the next big buildouts will happen.

Why Hydrogen Is Hard to Move

- Tiny molecules, big headaches: Hydrogen is the smallest element in the universe, which means it leaks easily from pipelines and fittings designed for natural gas.

- It embrittles steel, weakening pipelines over time and increasing the risk of cracks or failures.

- Because it’s less energy-dense per volume than natural gas, you need 3x the volume to move the same energy – making transport inherently less efficient.

Existing vs Planned Hydrogen Pipeline Networks

- Today, the world has only about 7,500 km of dedicated hydrogen pipelines – mostly in Europe and the US Gulf Coast.

- In comparison, natural gas has millions of kilometers of pipeline, meaning hydrogen has decades of catching up to do.

- Planned projects aim to change that fast:

| Region | Current H₂ Pipelines (km) | Planned by 2030 (km) |

|---|---|---|

| EU | ~2,300 | ~28,000 |

| US | ~1,600 | ~15,000 |

| Asia | ~1,000 | ~10,000 |

These massive buildouts are backed by public-private partnerships and could cut transport costs by 60%+ over the next decade.

Storage Options: Compressed, Liquid, Ammonia Carriers

- Compressed hydrogen (350–700 bar): Cheapest today, but requires heavy, high-pressure tanks.

- Liquid hydrogen (-253°C): Very energy-intensive to cool, but allows higher energy density.

- Ammonia carriers: Convert hydrogen into ammonia (NH₃) for easier shipping, then reconvert at destination. Already popular for long-distance sea transport.

Bottom line: No single solution wins – most regions will need a hybrid infrastructure model (pipelines for short-haul, ammonia or liquid for long-haul).

Policy and Regulation Landscape

If you want to know where hydrogen will really take off, don’t just follow the technology – follow the policy money.

Because the truth is: no clean energy revolution has ever scaled without strong government backing, and green hydrogen is no different. The current momentum we see today is being fueled by massive public subsidies, strategic roadmaps, and policy carrots designed to make hydrogen economically competitive.

Let’s break it down region by region.

EU Hydrogen Strategy: Subsidies on Steroids

- The European Union is arguably the most aggressive region on the planet when it comes to green hydrogen.

- Through the EU Hydrogen Strategy, they’ve set a goal of producing 10 million tons of renewable hydrogen annually by 2030, plus another 10 million tons imported.

- The EU Innovation Fund and Hydrogen Bank are funneling billions of euros in grants and contracts-for-difference (CfDs) to lower the cost gap between green and fossil hydrogen.

- Many member states (Germany, Spain, Netherlands) offer feed-in tariffs, tax credits, and low-interest loans to jumpstart electrolyzer projects and hydrogen valleys.

Bottom line: In the EU, if you build it, Brussels will pay for half of it.

US Inflation Reduction Act (IRA): The Game-Changer

- The US was late to the hydrogen party, but they showed up with a giant wallet.

- The 2022 Inflation Reduction Act (IRA) introduced the Section 45V clean hydrogen production tax credit – up to $3/kg of green hydrogen produced, for 10 years.

- That’s the single biggest hydrogen subsidy in history, slashing LCOH costs by up to 80%.

- On top of that, the Department of Energy is funding $7 billion for regional hydrogen hubs (H2Hubs) across the country.

- These hubs will cluster production, transport, and demand to create self-sustaining hydrogen ecosystems.

In short: The IRA turned the US from a hydrogen laggard into a serious contender overnight.

Asia-Pacific Hydrogen Roadmaps: Fast Followers

- Japan, South Korea, Australia, and China are taking a strategic, export-driven approach to hydrogen.

- Japan and Korea offer generous CAPEX subsidies, fuel cell vehicle incentives, and guaranteed offtake agreements for industrial buyers.

- Australia is building massive green hydrogen and ammonia export terminals, especially in Western Australia, backed by federal and state funding.

- China is quietly scaling up electrolyzer manufacturing capacity and fuel cell supply chains, positioning itself as a future low-cost hydrogen equipment powerhouse.

Table: Policy Incentives by Region

| Region | Key Incentives | 2030 Target |

|---|---|---|

| EU | Grants, CfDs, loans, tariffs | 20 Mt H₂ (10 Mt domestic + 10 Mt import) |

| US | $3/kg tax credit (45V), $7B for hubs | 10 Mt H₂ |

| Asia-Pacific | CAPEX grants, offtake deals, export support | 12–15 Mt H₂ |

Environmental & Safety Concerns

While green hydrogen is often seen as the hero of decarbonization, it’s not a silver bullet. There are still critical environmental and safety challenges that can’t be ignored. Let’s break down the three biggest ones-energy losses, water use, and safety myths-so you can understand what’s real and what’s hype.

Energy Losses in Conversion

Hydrogen is an energy carrier, not a primary energy source. And every time you convert energy, you lose some of it.

Here’s the reality:

| Step | Energy Input | Efficiency (%) |

|---|---|---|

| Electrolysis (electric → H₂) | 100 kWh | ~70% |

| Compression & storage | 70 kWh | ~90% |

| Fuel cell (H₂ → electric) | 63 kWh | ~50% |

By the time green hydrogen is turned back into usable electricity, more than half the energy is gone. That’s why many experts argue it’s better to use electricity directly where possible, and reserve hydrogen for applications where batteries can’t do the job (like steelmaking or shipping).

Water Use in Electrolysis

Producing hydrogen also requires water-and a lot of clean water at that. On average, electrolysis consumes about 9 liters of purified water per kilogram of hydrogen.

For context:

- A 1 GW electrolyzer plant could consume over 3 million liters per day.

- In water-scarce regions, this could put extra stress on local supplies.

Solutions are emerging, like desalination or using treated wastewater, but these add cost and complexity. Any large-scale hydrogen rollout must factor in local water availability from the start.

Hydrogen Safety: Myths vs Reality

Hydrogen has a reputation for being dangerous-thanks largely to the Hindenburg disaster. But much of that fear is outdated or exaggerated.

Facts that often get overlooked:

- Hydrogen is the lightest gas, so leaks dissipate quickly into the air.

- It has a wide flammability range, but ignites only in specific concentrations (4–75% in air).

- Modern systems use leak detectors, ventilation, and flame arrestors to reduce risk dramatically.

Yes, hydrogen is flammable-but so is natural gas, gasoline, and diesel. With proper engineering and safety protocols, hydrogen can be handled safely in industrial environments.

Key takeaway: Green hydrogen’s environmental footprint and safety risks are real-but manageable. Energy efficiency losses and water demand require smart planning, and safety requires strict standards. But none of these are dealbreakers for scaling hydrogen if managed well.

Top Industry Players & Their Bets

Green hydrogen isn’t just a science experiment anymore – it’s big business. The world’s largest energy companies, tech innovators, and industrial giants are all placing bets on hydrogen. Knowing who these players are will help you understand where the market is really heading (and who’s likely to win).

Energy Majors: Betting on Scale

The big oil & gas companies are reinventing themselves for the energy transition. Their strategy? Use their deep pockets, infrastructure, and global reach to dominate hydrogen production and distribution.

| Company | Role/Focus | Flagship Project |

|---|---|---|

| Shell | Large-scale green hydrogen production | Holland Hydrogen I (Netherlands) |

| BP | Integrated hydrogen hubs | H2Teesside (UK) |

| TotalEnergies | Renewable-powered hydrogen plants | Masshylia (France) |

They see hydrogen as the future “molecule” to replace oil molecules – and they want to own the supply chains before anyone else does.

Tech Players: Cracking the Cost Curve

Meanwhile, clean tech companies are trying to slash the cost of electrolysis – the holy grail for making green hydrogen competitive with fossil fuels.

| Company | Role/Focus | Flagship Project |

|---|---|---|

| Siemens Energy | PEM electrolyzer manufacturing | REFHYNE II (Germany) |

| ITM Power | Modular electrolysis systems | Linde Gigafactory (UK) |

| Nel Hydrogen | High-efficiency alkaline tech | Herøya Electrolyzer Plant (Norway) |

These players don’t care about selling hydrogen—they want to sell the machines that make it, at massive scale.

Industrial Offtakers: Creating the Demand

And then there are the heavy industrials. They’re not building electrolyzers-they’re the customers who will buy all that hydrogen, turning it into steel, ammonia, or fertilizers.

| Company | Role/Focus | Flagship Project |

|---|---|---|

| ArcelorMittal | Green steel production | Hamburg Hydrogen DRI (Germany) |

| Yara | Green ammonia & fertilizers | Yara Pilbara Renewable Ammonia (Australia) |

| Thyssenkrupp | Hydrogen-based steelmaking | tkH2Steel (Germany) |

They are critical because no demand = no market. These off-takers create the pull that attracts investment.

Key takeaway: The hydrogen race is no longer theoretical. The biggest companies on Earth are pouring billions into building supply, cutting costs, and locking in demand. Where these players go next will shape the future hydrogen economy.

The Road to 2030: Forecasts & Scenarios

If you think green hydrogen is still “far future,” think again. The 2030 horizon is closer than most companies realize – and according to leading analysts, the next five years will decide who wins the hydrogen race. This is not just about technology anymore. It’s about timing, scale, and strategy.

Let’s break down what the future might actually look like – based on projections from the International Energy Agency (IEA), BloombergNEF (BNEF), and a bit of realistic market sense.

IEA & BNEF Projections: Rapid Growth, If the Money Flows

Both IEA and BNEF see green hydrogen going from today’s niche pilot projects to industrial scale by 2030 – if investment keeps accelerating.

- IEA Net Zero Scenario: Projects over 500 GW of electrolyzer capacity by 2030, supplying about 150 million tons of hydrogen annually. This would cut emissions by 2 gigatons CO₂ per year.

- BNEF’s Economic View: Forecasts green hydrogen costs dropping to $1–1.5/kg by 2030 in regions with cheap renewables (Middle East, Australia, Chile, parts of the US). That’s competitive with natural gas-based hydrogen.

- Investment Need: Around $1.4 trillion cumulative capital will be required between now and 2030 – covering electrolyzers, renewables, pipelines, and storage.

In short: if capital keeps coming, cost parity will happen. If not, hydrogen will stay stuck in the demo phase.

Potential Tipping Points: When It Suddenly Becomes Mainstream

Hydrogen won’t scale linearly – it will hit tipping points where momentum snowballs. Watch for these:

- Carbon pricing or border taxes that penalize fossil fuels, making green hydrogen suddenly cheaper on a relative basis.

- Gigafactories for electrolyzers slashing CAPEX costs by 50%+ via economies of scale.

- Massive offtake deals between industrial giants and energy suppliers, guaranteeing demand for decades.

- Hydrogen infrastructure integration into existing natural gas networks, lowering transport costs dramatically.

Once two or three of these collide, the transition goes from “interesting pilot” to “unstoppable industry.”

Competitive Landscape 2030: Who Will Be Ahead?

By 2030, expect a three-layer market to emerge:

- Low-cost producers: Countries with abundant renewables (Australia, Saudi Arabia, Chile) will export cheap hydrogen and ammonia.

- Tech champions: Companies that mastered electrolyzer manufacturing (Siemens Energy, Nel, ITM Power) will dominate the supply chain and margins.

- Industrial first movers: Steel, chemicals, and shipping companies that secured early hydrogen supply will gain a cost advantage their competitors can’t easily catch up to.

In other words: the hydrogen race is really a race for cost advantage and customer lock-in. By 2030, the winners will already be pulling away – and the laggards may be locked out of the clean energy economy entirely.

Key takeaway: Hydrogen’s 2030 future is not guaranteed – but it’s highly plausible. The next five years are make-or-break. Companies that invest, partner, and scale now could own the backbone of tomorrow’s clean industrial system.

Conclusion + CTA

Why Hydrogen Will Reshape Industrial Energy

Let’s be real – the industrial energy system hasn’t changed much in decades. It’s still built on fossil fuels, centralized plants, and slow-moving supply chains. But green hydrogen is quietly rewriting the rulebook.

Throughout this article, we’ve seen how the cost of electrolyzers is dropping, how global policies are unlocking billions in incentives, and how corporations from Shell to Siemens are betting big on hydrogen. These aren’t fringe signals. They’re signs of an accelerating shift – one that could reshape how industries power themselves, produce materials, and trade globally.

Hydrogen isn’t just a “clean fuel.” It’s a strategic enabler. It can decarbonize hard-to-abate sectors like steel, cement, shipping, and fertilizers – sectors that account for a massive chunk of global emissions. If you’re running a plant, designing energy systems, or managing supply chains, ignoring hydrogen is no longer a safe option.

How Companies Can Start Preparing

If you want to be on the winning side of this transition, you can’t wait until 2030. You have to plant your flag now, while the ground is still soft. Here’s how smart companies are approaching it:

- Map your emissions hotspots and identify processes that could switch to hydrogen (direct reduction of iron, ammonia production, industrial heat, heavy transport).

- Run feasibility studies and pilots with electrolyzer vendors, EPC firms, and renewable energy developers to understand integration challenges early.

- Build long-term offtake agreements or partnerships with future hydrogen producers – locking in low prices and supply security before competition spikes.

- Tap into government incentives like the US IRA hydrogen tax credits, EU Hydrogen Bank contracts, or APAC green hydrogen subsidies to de-risk investments.

Think of it like digital transformation – the companies that acted early captured all the value. Hydrogen will be the same story, just at industrial scale.

🚀 Ready to Dive Deeper?

Hydrogen is moving from concept to competitive advantage. The window to lead is open – but not for long.

If you’re serious about positioning your company at the front of this revolution, here’s your next step:

🔗 Explore our case studies of real-world hydrogen projects proving the economics and technology

📩 Subscribe to our newsletter to get the latest market insights, policy updates, and cost trend analysis delivered to your inbox

The future of industrial energy is being built right now.

The only question is: Will you be part of it?

Thanks for article