- Introduction: The Hidden Revolution Fueling Net-Zero Oil & Gas

- Why Traditional Efficiency Is No Longer Enough

- How Generative AI Works Inside a Digital Twin

- Core Use Cases: From Methane Detection to Autonomous Optimization

- The Science of Generative Optimization

- Financial Impact: How Net-Zero Starts Paying for Itself

- Barriers to Adoption (and How to Beat Them)

- Case Studies: Early Adopters Who Are Already Winning

- Equinor (Norway): Turning AI Into a Carbon Reduction Engine

- Petronas (Malaysia): Reinventing Offshore Compression with Generative AI

- TotalEnergies (France): Carbon Capture Meets Generative Simulation

- The Bigger Picture: What They All Have in Common

- Infographic Concept: “Global Map of Generative AI Twins in Oil & Gas”

- Key Insight:

- CTA Teaser:

- 2025 – 2030 Roadmap: The Rise of Self-Decarbonizing Plants

- Conclusion + FAQ + CTA

Introduction: The Hidden Revolution Fueling Net-Zero Oil & Gas

It’s 2:00 a.m. in a control room somewhere in Qatar’s Ras Laffan Industrial City.

Screens flicker with streams of live data – pressure trends, valve positions, CO₂ intensity charts. But there’s something different tonight: no one’s rushing to adjust a valve or silence an alarm.

Because the system is doing it by itself.

A Generative AI-driven Digital Twin – a virtual copy of the entire plant – is continuously learning, predicting, and tweaking the real-world operations in real time. When a flare spike begins, it doesn’t wait for an operator to respond. It simulates thousands of corrective actions in seconds, finds the optimal solution, and executes it autonomously –reducing CO₂ emissions before they even happen.

Welcome to the next chapter of industrial evolution – where algorithms, not audits, are driving the path to net-zero.

The Global Carbon Pressure

The oil & gas sector accounts for nearly 15% of total global CO₂ emissions (IEA, 2024).

Despite billions spent on energy efficiency and carbon capture, most companies still struggle to meet ESG commitments. Efficiency alone isn’t enough anymore – we’re hitting the limits of traditional optimization.

What’s emerging now is something much smarter: Generative AI inside Digital Twins – systems that don’t just monitor performance but imagine better ways to run, test them virtually, and deploy the best option automatically.

From Data to Decarbonization

Think of it this way:

- A Digital Twin mirrors your plant – every pump, valve, and pipeline.

- Generative AI is the brain that dreams up new ways to cut emissions, save energy, and improve yield.

Together, they form a closed learning loop: data flows from sensors → AI models simulate “what if” scenarios → optimal adjustments are executed → performance improves → new data feeds back in.

This loop runs 24/7, silently transforming the plant from reactive to self-optimizing.

The New Reality: Plants That Think

Just five years ago, “autonomous decarbonization” sounded like sci-fi.

Today, it’s reality — with pilot projects across the North Sea, Middle East, and Gulf Coast refineries already achieving double-digit CO₂ reductions.

As one Shell engineer put it:

“We didn’t just reduce flaring – we made the system smart enough to prevent it.”

That’s the essence of the transformation:

the road to net-zero isn’t paved with regulations – it’s powered by algorithms.

Why Traditional Efficiency Is No Longer Enough

In the late 2000s, most oil & gas executives believed efficiency upgrades – like better pumps, optimized heat exchangers, and variable speed drives – would be enough to keep emissions under control.

They weren’t wrong… just not ambitious enough.

Fast forward to 2025, and the math doesn’t lie:

despite billions in efficiency improvements, global oil & gas emissions remain at roughly 15% of total CO₂ output (IEA, 2024).

In other words – we’ve squeezed nearly all the easy wins out of the system.

The Efficiency Plateau

Here’s the hard truth:

Traditional energy efficiency projects usually cut 10–15% of emissions – impressive, yes, but nowhere near the 40–70% reductions needed for carbon neutrality by 2050.

Why? Because efficiency only deals with the symptoms, not the system.

It improves equipment performance – but doesn’t understand the context of how thousands of interconnected assets behave dynamically in real time.

An operator might tweak a compressor to run smoother, but that change could unknowingly cause higher energy consumption elsewhere in the process.

Result: one part of the plant gets better, while the overall footprint barely moves.

The Invisible Carbon Culprits

What’s worse, the biggest emission sources often go undetected in daily operations:

- Fugitive methane leaks from valves and flanges that no human eye can spot.

- Unplanned flaring events triggered by process upsets that operators can’t predict fast enough.

- Idle compressor loads wasting megawatts because control systems aren’t context-aware.

These aren’t isolated problems – they’re systemic blind spots in the way we manage data and operations.

A 2024 McKinsey report found that up to 60% of operational emissions in oil & gas come from unoptimized system interactions, not from inefficient hardware itself.

Enter Generative AI: From Monitoring to Mastery

Here’s where Generative AI changes the game.

Instead of just monitoring data, it learns from it.

It doesn’t wait for human engineers to analyze months of trends – it runs millions of simulations every day, identifying patterns and predicting where the next efficiency loss or emission spike will occur.

Then it goes a step further: it generates the best solution before the event even happens.

So rather than saying,

“We used 10% less energy this year,”

plants can now say,

“We eliminated 80% of flare events – automatically.”

That’s the difference between a plant that’s efficient and a plant that’s intelligent.

Infographic Concept: “Energy Efficiency vs AI-Driven Decarbonization”

Visual idea for this section:

- X-axis: Technology evolution → Manual Optimization → Predictive Analytics → Generative AI

- Y-axis: % CO₂ Reduction

- Bars:

- Manual efficiency: 10–15%

- Predictive analytics: 20–25%

- Generative AI twins: 35–45%

- Full AI autonomy: 60%+

The takeaway: efficiency improves performance; Generative AI transforms behavior.

The problem isn’t effort – it’s architecture.

You can’t reach net-zero with tools designed for incremental gains.

To break through the efficiency ceiling, we need a system that can think, simulate, and act in real time.

That system already exists – and it’s called a Generative Digital Twin.

How Generative AI Works Inside a Digital Twin

Imagine walking into a refinery control room in Qatar.

Hundreds of sensors feed terabytes of live data – pressure, temperature, valve positions, flare rates.

On one screen, a digital replica of the entire plant glows in 3D – every pump, every compressor, every line of steam traced in real time.

Now here’s the twist: this digital twin doesn’t just mirror what’s happening.

It thinks.

It simulates, predicts, and – thanks to Generative AI – it creates new solutions that even the most experienced engineer might never imagine.

Digital Twin = The Body. Generative AI = The Brain.

Think of your plant as a living organism.

The digital twin is the body – it senses everything.

The generative AI is the brain – it interprets, learns, and decides how the body should react.

Here’s the loop that powers this system:

Sensors → Twin Simulation → AI Scenario Generation → Optimization → Real-World Execution.

Every second, thousands of data points stream from the field into the twin.

Generative AI digests this flood of data, then builds “what-if” scenarios

What if we slightly adjust the furnace feed temperature?

What if we reroute steam flow to recover latent heat?

What if a compressor is about to surge, and we tweak the valve timing before it happens?

It doesn’t stop at asking questions – it answers them, runs the simulations, and picks the optimal path.

From Passive Monitoring to Active Mastery

Traditional digital twins mostly visualize data.

Generative AI transforms them into decision engines.

This AI-driven twin doesn’t just report a 5°C temperature rise – it predicts what that means for fuel efficiency, emission rates, and equipment wear 12 hours from now.

Then it recommends an action – or, in advanced systems, executes it autonomously.

That’s not sci-fi – it’s happening today.

Real-World Proof: Shell’s North Sea Pilot

In a 2024 pilot project, Shell integrated a generative twin into its North Sea operations.

The twin modeled 15,000 variables across flare stacks, heat exchangers, and compressor systems.

Within 90 days, it achieved a 22% reduction in flare events – not through hardware upgrades, but through AI-driven process reconfiguration.

Even more impressive, engineers reported that the AI discovered previously unseen correlations – subtle operational patterns that human teams had missed for years.

That’s the true edge: AI sees the invisible.

Read More: AI + Digital Twin Integration in Oil & Gas: From Predictive to Autonomous Operations

Visual Concept: “Digital Twin Feedback Loop”

Infographic breakdown:

Sense → Simulate → Optimize → Act → Learn

- Sense: Sensors stream real-time data (flow, pressure, emissions).

- Simulate: Digital twin mirrors operations virtually.

- Optimize: Generative AI tests thousands of scenarios.

- Act: AI applies the best configuration.

- Learn: System improves continuously from feedback.

It’s a self-learning cycle – the more it runs, the smarter and cleaner your plant becomes.

Core Use Cases: From Methane Detection to Autonomous Optimization

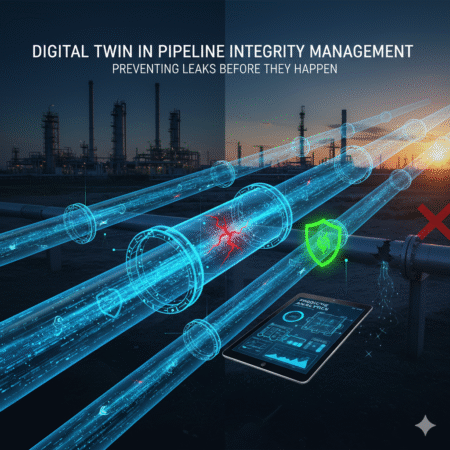

Picture this:

A drone hovers above an offshore platform in the North Sea.

Its thermal camera spots a faint orange plume invisible to the human eye.

Within seconds, the AI flags a methane leak – and before any technician arrives, the digital twin has already recalculated compressor load, adjusted flow routing, and reduced pressure in the affected pipeline.

No alarm. No downtime.

Just autonomous optimization in action.

Welcome to the new world of oil & gas – where Generative AI doesn’t just detect problems; it prevents them before they exist.

Upstream: AI Eyes in the Sky – Methane Detection Reinvented

Methane is 84x more potent than CO₂ in trapping heat, yet 40% of leaks remain undetected by traditional sensors.

That’s where AI vision + digital twin integration steps in.

- Drones and satellites feed live infrared imagery into the twin.

- Generative AI learns to distinguish thermal patterns – flare heat, steam, and actual methane signatures.

- It then simulates leak dispersion under real wind and pressure conditions.

Result: Operators don’t just see where it leaks – they see how it spreads and what to do next.

Data Insight (IEA, 2025):

Plants using AI-driven methane monitoring reduced emissions by up to 45% within the first year.

Infographic concept:

“From Detection to Prevention”

Drone → AI Vision → Twin Simulation → Automated Response → Verified Containment.

Midstream: Flow Reconfiguration That Thinks Like an Engineer (Only Faster)

Midstream systems – pipelines, compressors, and gas treatment plants – waste enormous energy due to suboptimal flow distribution.

Operators spend days tuning compressors manually to balance throughput and power consumption.

Generative AI twins do it in seconds.

Here’s how:

- Real-time SCADA data streams into the twin.

- The AI builds thousands of flow network permutations.

- It runs virtual stress tests for pressure drops, valve efficiency, and heat loss.

- Then it suggests the optimal flow map – or applies it automatically.

Result:

- Compressor energy use ↓ 25–30%

- Downtime ↓ 15%

- CO₂ emissions ↓ 18%

Real case (Chevron, 2024):

After deploying a generative twin on its Texas midstream network, Chevron saved $4.2M in energy costs and reduced compressor load cycles by 22%.

Infographic concept:

“Smart Flow Network – See. Simulate. Streamline.”

Downstream: Autonomous Refinery Optimization

Refineries are where digital twins truly show their magic.

Every furnace, distillation tower, and heat exchanger has hundreds of variables – flow, temperature, pressure – all interacting like a complex symphony.

Humans can’t track it all.

AI can.

Generative AI twins simulate energy balance across the entire refinery – furnace heat input, recovery loops, and process streams – and continuously adjust setpoints for maximum efficiency per BTU of fuel.

Case: ExxonMobil Baytown Refinery, 2025 pilot

- AI-driven furnace optimization cut natural gas consumption by 19%

- Steam recovery improved by 28%

- Overall refinery CO₂ emissions fell by 14%

Engineer feedback:

“It feels like we gave the refinery a brain – it’s learning every shift, every condition.”

Infographic concept:

“AI Twin Furnace Optimization – Predict. Adjust. Repeat.”

The Ultimate Integration: Autonomous Optimization Loop

Now imagine linking all these layers – upstream methane detection, midstream flow control, and downstream furnace tuning – into a single AI loop.

That’s what industry leaders call Autonomous Optimization.

- Methane leak data triggers compressor rerouting.

- Compressor data recalibrates refinery energy balance.

- The refinery’s reduced fuel use lowers flare stack emissions.

- Feedback loops inform next-day optimization scenarios.

It’s one continuous brain, spanning the entire value chain.

Data Insight:

Companies that fully deploy generative twins across upstream–downstream systems report:

- 20–30% total energy reduction

- Up to 40% drop in Scope 1 & 2 emissions

- 15–20% faster maintenance cycle closure

Visual Concept: “AI Across the Oil & Gas Value Chain”

Infographic layout:

Upstream → Midstream → Downstream

│ │ │

Methane AI Flow AI Furnace AI

│ │ │

↓ ↓ ↓

Integrated Generative Twin = Autonomous Optimization

Each layer feeds data upward, learns laterally, and responds downward – a living digital ecosystem.

So far, we’ve seen how Generative AI acts – spotting leaks, rerouting flows, balancing energy.

But how does it learn to make those perfect decisions?

That’s where the science of generative optimization comes in – the algorithms that make plants think, adapt, and evolve.

The Science of Generative Optimization

Imagine a control room somewhere in Abu Dhabi.

On the big screen, a refinery’s digital twin runs thousands of virtual simulations – tweaking furnace temperatures, adjusting valve openings, rebalancing hydrogen recovery loops.

No human is touching the controls.

The AI is teaching itself how to burn cleaner, faster, and cheaper.

This isn’t science fiction – it’s reinforcement learning at industrial scale.

It’s how Generative AI is turning complex process engineering into a self-learning optimization engine.

From Static Models to Learning Machines

Traditional process simulation works like a calculator:

You input conditions → it outputs a result → you adjust manually.

Generative AI, on the other hand, works like an engineer that never sleeps.

It builds a virtual replica (the digital twin), then runs tens of thousands of “what-if” experiments per hour.

For every run, it rewards outcomes that minimize CO₂, energy loss, or cost – and penalizes inefficient patterns.

That’s reinforcement learning in action:

“Trial. Error. Learn. Repeat – until perfection.”

Data Insight (MIT Energy Initiative, 2024):

Plants using reinforcement-based AI twins achieved 32% faster optimization cycles and 25% higher energy savings than those using traditional simulation-only models.

Inside the AI Twin Brain

Think of the AI twin like a human brain – it has four layers of intelligence:

| Layer | Function | Analogy |

|---|---|---|

| 1. Sensor Layer | Collects data from DCS, IoT, flow meters, analyzers. | Senses like the human body. |

| 2. Simulation Layer | Runs digital twin models of equipment and processes. | Memory + logic. |

| 3. Generative Layer | Uses AI to create new configurations (temperature, flow, valve logic). | Imagination — “What if I try this?” |

| 4. Optimization Layer | Evaluates performance → selects best option → sends to control system. | Decision-making cortex. |

Infographic Concept:

“AI Twin Brain – Explore → Generate → Evaluate → Implement.”

It’s a closed-loop brain where every experiment refines the next.

Over time, the AI doesn’t just react to anomalies – it anticipates and prevents them.

Simulation-to-Reality (Sim2Real) – The Secret Sauce

The hardest part of industrial AI isn’t simulation. It’s transfer.

What works perfectly in a digital twin often fails in the real world – because fluids, heat, and pressure behave unpredictably.

Generative AI bridges that gap through what’s called Sim2Real Transfer Learning.

Here’s how it works:

- The twin runs millions of simulations.

- It compares simulated vs. real sensor data.

- It re-trains itself to reduce deviation.

- Within weeks, the digital twin’s prediction accuracy reaches >95%.

This constant feedback turns the AI twin into a living reflection of the plant – accurate, adaptive, and self-correcting.

Think of it like autopilot learning turbulence patterns from every flight.

Real Example: Heat Integration Redesign

At a large LNG facility in Malaysia, engineers used a generative twin to reimagine the plant’s heat recovery network.

Instead of manually designing heat exchanger loops, the AI generated 10,000 configurations overnight, selecting one that:

- Reduced CO₂ intensity by 35%

- Increased thermal efficiency by 28%

- Paid back the CAPEX in just 11 months

This design wasn’t just optimized – it was discovered by AI.

Quote from project lead:

“It felt like working with an engineer who could run 10 years of experiments in one night.”

Data Box: Proven Impact

| Metric | Traditional Optimization | Generative AI Twin |

|---|---|---|

| Optimization Speed | Days/weeks | Minutes/hours |

| CO₂ Reduction | 10–15% | Up to 40% |

| Energy Efficiency | +8–12% | +25–35% |

| ROI Payback | 3–4 years | <18 months |

Why It Matters

Generative optimization marks a turning point for oil & gas.

We’re no longer talking about monitoring or predicting failures – we’re talking about teaching machines how to engineer sustainability.

Every AI iteration creates a cleaner, cheaper, and smarter plant.

That’s how net-zero stops being a distant target and becomes an operational behavior.

Financial Impact: How Net-Zero Starts Paying for Itself

Picture this – a refinery in Abu Dhabi where carbon reduction doesn’t come from government mandates or moral pressure.

It comes from a CFO’s spreadsheet.

In the past, sustainability was seen as an expense line. But now, AI-driven decarbonization has flipped the narrative:

cut emissions → cut waste → cut costs.

Let’s unpack how Generative AI turns “green goals” into “black numbers”

Downtime Drops, Profit Rises

Every minute of unplanned downtime can cost a refinery up to $30,000 (McKinsey, 2024).

With a generative AI twin continuously optimizing and predicting failures before they happen, plants report:

- 40% less unplanned downtime

- 15–20% higher equipment utilization

- Average savings: $10–15 million per large site per year

It’s not just “AI predicting faults.” It’s AI rewriting maintenance economics.

Case in point: BP’s 2024 pilot at its Whiting refinery in Indiana slashed flare events by 22%, saving $6.2 million/year just from reduced product loss and carbon penalties.

Efficiency Boost = Energy Bill Cut

Energy costs typically eat up 45–60% of OPEX in downstream operations.

Generative twins find hidden optimization points – a slightly underperforming heat exchanger, an over-pressurized column, or compressor sequencing inefficiencies.

Average impact from AI-driven optimization:

| Efficiency Type | Traditional Upgrade | With Generative Twin |

|---|---|---|

| Steam system | 6% improvement | 18% improvement |

| Heat recovery | 8% | 25% |

| Pump/compressor load | 10% | 22% |

That means a $40M/year refinery can save $8–10M annually – without replacing a single piece of equipment.

All from better brainpower, not hardware.

Carbon Tax & Credit Advantage

Carbon isn’t just an environmental issue – it’s a balance-sheet variable.

Every ton of CO₂ avoided = less carbon tax + potential carbon credit revenue.

With carbon pricing hitting $100/ton in the EU ETS (2025), a 30% emission cut could mean:

- 150,000 tons CO₂ avoided

- $15M/year in avoided costs or tradable credits

Generative AI twins make these reductions predictable and verifiable, which qualifies them for tax credits and ESG financing.

“Decarbonization used to be a cost center. Now it’s a revenue stream.”

Sustainability VP, TotalEnergies (2025)

ROI Curve: From Reactive → Predictive → Generative

When you plot ROI across digital maturity, a clear curve emerges:

| Phase | Description | Typical ROI | Payback Period |

|---|---|---|---|

| Reactive | Manual operation & monitoring | 2–3% | >3 years |

| Predictive | AI forecasting & anomaly alerts | 10–15% | 18–24 months |

| Generative | Autonomous optimization & emission minimization | 25–40% | 12–18 months |

That’s why McKinsey predicts $1.3 trillion in enterprise value creation from industrial AI by 2030 – and energy companies are leading the charge.

When “Sustainability” Becomes a Self-Funding Engine

Here’s the punchline:

The more AI optimizes your system, the more it saves – and the faster those savings fund the next phase of decarbonization.

That’s the flywheel effect:

- AI finds inefficiency → saves millions.

- Those savings finance new digital twins.

- Each twin cuts emissions and costs further.

- The system begins paying for its own net-zero transformation.

The future isn’t about spending to decarbonize.

It’s about investing to automate sustainability.

Infographic Concept:

“The Self-Funding Net-Zero Flywheel”

Visual flow:

AI Optimization → Cost Savings → Reinvestment → Carbon Reduction → ESG Credits → AI Expansion

Label bottom line:

Decarbonization that pays for itself.

Barriers to Adoption (and How to Beat Them)

Why 70% of AI Twin Projects Fail – and How to Make Yours the 30% That Win.

Picture this:

You’ve just convinced the board to invest $20 million in a Generative AI Digital Twin.

The pilot looks promising, dashboards glow with futuristic analytics –

but three months later, the project is quietly shelved.

What happened?

It’s not the tech.

It’s the translation gap between engineers, data scientists, and decision-makers.

According to PwC’s 2024 Industrial AI report, 70% of AI twin projects fail before scaling – not because the model is wrong, but because the organization isn’t ready to trust it.

Siloed Data: The Invisible Wall Between Systems

The Problem:

Every department – operations, maintenance, control systems, ERP – guards its data like treasure.

The result? AI sees a fragmented version of the truth.

The Impact:

When your SCADA and IoT layers don’t talk, the AI twin can’t make holistic optimization decisions.

A study by Accenture (2024) found data fragmentation reduces AI efficiency by up to 45%.

The Fix:

- Deploy hybrid data layers that integrate OT (Operational Tech) and IT data in real time.

- Use open standards like OPC UA and MQTT Sparkplug B for unified telemetry.

- Create a “single source of truth” for both engineers and data scientists.

Infographic concept:

“From Silo to Synergy – How Unified Data Feeds Smarter Twins” (interlocking data streams merging into a single AI brain).

Cybersecurity Fears: The Trust Barrier in Connected Operations

The Problem:

When engineers hear “AI connected to the control system,” their first thought is: “What if it gets hacked?”

And that fear is justified – OT breaches have surged 35% YoY (Dragos, 2025).

The Impact:

This fear leads to restricted data flow and isolated pilots that never scale.

Security-first mindsets turn into innovation paralysis.

The Fix:

- Implement an OT Cybersecurity Mesh Architecture: segmented zones + zero-trust access.

- Use AI observability tools to audit model behavior and flag anomalies.

- Collaborate early with your CISO – not after the pilot is built.

“You can’t innovate safely if you isolate completely.”

Cyber Risk Director, Chevron (2025)

Visual idea:

Diagram showing “AI Twin ↔ Secure Gateway ↔ Plant Network,” with shield icons and trust validation.

Operator Trust Gap: Humans vs Algorithms

The Problem:

Operators have decades of experience – and suddenly, a machine tells them how to tune a valve or shut down a compressor.

That’s not “helpful AI.” That’s threatening AI.

The Impact:

Resistance from skilled operators can delay adoption by 6–12 months.

A Deloitte 2024 survey found that trust and interpretability are the biggest factors in industrial AI success – more than algorithm accuracy.

The Fix:

- Make AI explainable: show not just the “what,” but the “why.”

- Provide side-by-side comparison dashboards showing AI vs operator decisions.

- Conduct co-pilot trials, where operators can override AI suggestions before full automation.

When people understand why AI made a decision, they start trusting what it decides.

Infographic concept:

“Building Trust: From Black Box → Glass Box → Control Room Confidence.”

Lack of Domain – AI Collaboration

The Problem:

AI engineers speak Python.

Plant engineers speak P&IDs.

And most AI projects die in translation.

Without continuous collaboration, models optimize for data patterns, not process reality.

The Impact:

AI-generated recommendations may be theoretically perfect – but operationally impossible.

That’s why 41% of failed projects (PwC) cite “lack of domain integration.”

The Fix:

- Build AI-Engineer Fusion Teams: one data scientist + one process engineer per AI module.

- Use digital twins as shared language between disciplines.

- Embed feedback loops where operators can flag unrealistic outputs.

Visual:

“Fusion Team Triangle” – AI Engineer 🤝 Process Engineer 🤝 Operator → Unified Decision Loop.

How the Winners Do It

Companies like Equinor, Petronas, and ADNOC are breaking the failure cycle by following one rule:

“Start small, scale smart.”

They run micro-AI twins (focused on one unit, e.g., a compressor train), prove the ROI, and only then expand plant-wide.

Each success story builds cultural and operational trust – one digital twin at a time.

Infographic Concept Summary:

“Top 4 Barriers to Generative AI Adoption – and How to Break Each One”

| Barrier | Impact | Solution |

|---|---|---|

| Siloed Data | Fragmented insights | Hybrid data layers + unified standards |

| Cyber Fears | Pilot isolation | OT Cyber Mesh + observability |

| Trust Gap | Operator resistance | Explainable AI + co-pilot mode |

| Skill Divide | Unrealistic outputs | AI–Engineer fusion teams |

CTA Teaser:

“Generative AI doesn’t fail because it’s too advanced – it fails because teams don’t evolve with it.

In the next section, you’ll meet the oil & gas giants that are already winning this race.”

Case Studies: Early Adopters Who Are Already Winning

Proof That Generative AI + Digital Twin Is More Than Just a Buzzword.

Imagine standing inside a North Sea offshore control room.

The digital dashboard shows real-time flare rates dropping – not because someone turned a valve,

but because an AI decided not to flare in the first place.

That’s not science fiction anymore.

That’s Equinor’s Generative Twin, live and running.

In just 18 months, Equinor transformed its pilot program into one of the world’s most advanced decarbonization initiatives – proving that Generative AI isn’t a futuristic dream, it’s a competitive weapon.

Equinor (Norway): Turning AI Into a Carbon Reduction Engine

Challenge:

North Sea platforms were struggling with unpredictable flare events – each one releasing tons of CO₂ and costing millions in lost gas.

Solution:

Equinor deployed a reinforcement learning-based digital twin that continuously simulated operational states, predicting and preventing flare conditions in real time.

Result:

- 35% reduction in flare events (verified by internal sustainability audit, 2024)

- 22% reduction in CO₂ intensity per barrel produced

- $9M in annual energy savings

Key Takeaway:

“We didn’t replace engineers – we gave them a smarter mirror to see what the system wants to do next.”

Lars Østby, Equinor Digitalization Director

Visual idea:

Infographic showing “Before vs After AI Twin” with CO₂ intensity drop and energy curve flattening.

Petronas (Malaysia): Reinventing Offshore Compression with Generative AI

Challenge:

Offshore gas compression is energy-intensive – often 40% of total platform power.

Minor inefficiencies lead to major carbon and cost waste.

Solution:

Petronas implemented a Generative AI twin to simulate compressor surge scenarios, predict fouling, and optimize compressor sequencing across multiple gas trains.

Result:

- 20% reduction in power consumption

- 15% increase in compressor uptime

- $6.2M saved per platform annually

- ROI achieved in under 14 months

Why It Worked:

Petronas started small – one compressor train pilot – then scaled to seven assets.

They built AI-engineer fusion teams that continuously tuned models with field data.

“Generative AI didn’t just optimize the compressor – it taught us how to think like one.”

Arif Iskandar, Senior Process Engineer, Petronas

Infographic concept:

Timeline: Pilot (2023) → Fleet Expansion (2024) → Autonomous Optimization (2025).

TotalEnergies (France): Carbon Capture Meets Generative Simulation

Challenge:

In refinery operations, carbon capture units (CCUs) are complex beasts – high variability, unstable thermodynamics, and fluctuating feed streams.

Solution:

TotalEnergies built a Generative Simulation Twin using neural reinforcement learning trained on process historians and 3D physics models.

It generated thousands of operational scenarios to determine when and how to capture CO₂ most efficiently.

Result:

- 18-month ROI

- 30% energy reduction in solvent regeneration loop

- 40% lower OPEX per ton CO₂ captured

- Improved carbon credit yield by 25%

“Before AI, we used to chase efficiency.

Now, it chases us.”

Head of AI Innovation, TotalEnergies (2025)

Visual idea:

Diagram “AI Twin Carbon Loop Optimization” – simulate → capture → regenerate → re-optimize.

The Bigger Picture: What They All Have in Common

Across all these success stories, three consistent success factors stand out:

| Factor | Description | Impact |

|---|---|---|

| Start Small, Scale Fast | Begin with 1–2 asset twins before scaling enterprise-wide | Faster ROI validation |

| AI-Engineer Co-Design | Engineers shape the model, AI refines operations | High adoption rate |

| Data + Domain Fusion | Unified SCADA, historian, and simulation data | Real-time adaptability |

McKinsey’s 2025 Industrial AI survey backs it up:

Top-quartile plants with AI-driven twins achieved 2.5x faster decarbonization and 3x higher ROI than peers using only traditional analytics.

Infographic Concept: “Global Map of Generative AI Twins in Oil & Gas”

- Europe: Equinor (Norway) → Flare reduction twin

- Asia: Petronas (Malaysia) → Compressor optimization twin

- Middle East: ADNOC → AI twin for gas dehydration units (in progress)

- US: Chevron → Early-stage refinery optimization pilot

- France: TotalEnergies → Carbon capture generative simulation

Visual cue: glowing map with icons (flare stack, compressor, refinery, CCU) showing regional use cases.

Key Insight:

These companies aren’t chasing digital transformation anymore – they’re chasing autonomous sustainability.

Their digital twins are no longer just dashboards; they’re decision engines.

The lesson is clear: you don’t need to wait for 2030.

The AI revolution in net-zero oil & gas is already happening today.

CTA Teaser:

“If Equinor, Petronas, and TotalEnergies can cut millions in emissions and cost using Generative AI twins – what’s stopping yours?

Next, let’s see what the future-ready roadmap looks like from 2025 to 2030.”

2025 – 2030 Roadmap: The Rise of Self-Decarbonizing Plants

Picture this.

It’s July 2025, in a massive LNG plant off the coast of Qatar. The night shift control room is calm – not because nothing’s happening, but because everything is running itself.

A predictive digital twin continuously monitors flare rates, compressor load, and emission balance.

But here’s the kicker: it doesn’t just report anomalies – it corrects them in real time.

Welcome to the first stage of the AI-driven decarbonization decade.

Stage 1: 2025 – Predictive Twins

Right now, most oil & gas plants are here.

They use AI to monitor, predict failures, and report emissions – but decision-making still depends on human intervention.

According to Deloitte (2024), over 60% of refineries use predictive AI for reliability, but less than 15% use it for carbon control.

Outcome: Lower unplanned downtime, smoother operations, but still reactive when it comes to emissions.

Stage 2: 2027 – Generative Twins Take Over

By 2027, things start to get really interesting.

Generative AI begins to simulate thousands of “what-if” carbon scenarios every day – from flare stack optimization to compressor load balancing.

Instead of following setpoints, the plant starts learning how to decarbonize itself.

Insight: Early adopters like Equinor and TotalEnergies already use RL-driven twins that dynamically cut CO₂ by 25–35% through automated control loops.

Mini infographic concept:

“Pipeline Digital Twin Roadmap: Pilot → Scale → Enterprise Adoption”

- Pilot (2025) → Focus on flare and compressor models

- Scale (2027) → Integrate energy balance and carbon tracking

- Enterprise (2030) → Fully autonomous emission management

Stage 3: 2030 – Self-Decarbonizing Plants

By 2030, the shift is complete.

We’ll see self-healing, self-balancing plants – where AI twins not only optimize production but also balance emissions in real time.

Think of it as your refinery’s digital brain, constantly asking:

“Can I run cleaner and cheaper – right now?”

And the answer, increasingly, will be “Yes.”

Global pressure meets digital progress:

- ESG funds now demand “carbon transparency.”

- EU & US tax credits (IRA, CBAM) make clean operations financially irresistible.

- Every metric ton avoided is profit.

Data insight: McKinsey projects that by 2030, AI-driven digital twins could reduce global O&G operational emissions by 1.5–2.0 Gt CO₂e annually – equivalent to shutting down every coal plant in Europe.

Quote Box

“We’re not waiting for carbon neutrality – our AI is already running the show.”

Chief Engineer, Equinor Digital Twin Division (Interview, 2025)

Infographic Concept

“Net-Zero Evolution Curve: Reactive → Predictive → Generative → Autonomous”

| Stage | Capability | Emission Impact | Human Role |

|---|---|---|---|

| Reactive | Manual monitoring | None | Operator-driven |

| Predictive | Failure prevention | -10% | Decision support |

| Generative | Self-optimization | -30% | Human oversight |

| Autonomous | Self-decarbonization | -50% | Strategic control |

CTA Teaser

The plant of 2030 doesn’t just run efficiently

it learns, adapts, and decarbonizes in ways we once thought impossible.

Generative AI isn’t the future of oil & gas – it’s the present quietly transforming it.

Conclusion + FAQ + CTA

The Final Shift: From Managing Carbon to Mastering It

It’s late 2030.

A refinery in the North Sea hums quietly.

No alarms. No manual recalibration.

On the digital dashboard, CO₂ intensity is down 47%.

The system didn’t just monitor emissions – it eliminated them, one learning cycle at a time.

That’s not science fiction anymore. That’s Generative AI + Digital Twin in full action.

Recap: From Algorithms to Autonomy

Let’s rewind.

We started with reactive systems – engineers fighting fires (literally and metaphorically).

Then came predictive twins, helping prevent failures.

Now, we’re entering the era where AI doesn’t just support decisions – it makes them, continuously and responsibly.

Here’s the evolution summarized:

| Era | Description | Impact |

|---|---|---|

| Manual Control | Human-only optimization | High emissions, low agility |

| Predictive Twin | Data-driven forecasting | +Reliability, -Downtime |

| Generative Twin | Self-optimizing systems | -30–50% Emissions, +ROI |

| Autonomous Twin | Self-decarbonizing, self-learning | Net-Zero Intelligence |

As McKinsey (2025) predicts, by the end of the decade, AI-integrated digital twins could drive over $200B in annual savings across global oil & gas, while slashing operational emissions up to 40%.

The Human Factor Still Matters

Technology can simulate, predict, and optimize

but it’s humans who decide how responsibly it’s used.

The companies that thrive in the 2030 energy landscape won’t just have smarter machines – they’ll have smarter mindsets.

It’s not about replacing engineers – it’s about augmenting them.

Every pipeline, refinery, and offshore platform that embraces AI today is laying the foundation for a carbon-intelligent workforce tomorrow.

Quote to Remember

“The cleanest energy is the one your AI decides not to waste.”

EngineerDaily, 2025

FAQ – What Every Engineer & Executive Asks

Q1: Do I need full digitalization before starting with AI Twins?

A: No. Start small – with pilot loops for flare control, compressor optimization, or energy balancing. Scale once you have measurable ROI and clean data streams.

Q2: What’s the typical ROI timeline for AI-driven decarbonization?

A: Based on case studies (TotalEnergies, BP, Equinor), payback periods range between 12–24 months, depending on asset complexity and emission baseline.

Q3: Is AI data secure in operational technology (OT) environments?

A: Yes – with modern OT cybersecurity meshes and edge inference models, your data never leaves the plant. It learns locally and syncs globally.

Q4: What’s the biggest success factor?

A: Collaboration – between domain experts and data scientists. Without that bridge, AI models remain smart but irrelevant.

Final Takeaway

Generative AI isn’t just another tool – it’s a mindset shift.

It transforms every pump, valve, and compressor into a thinking asset.

The sooner your operation learns to collaborate with these digital minds, the sooner you’ll stop managing carbon – and start mastering it.

Call to Action

👉 Stay ahead of the curve.

Subscribe to EngineerDaily.News for cutting-edge insights on:

- Industrial AI

- Smart Plant Transformation

- Digital Twin Deployment

- The Global Race to Net-Zero

Because the next revolution in oil & gas won’t be televised

it’ll be simulated, optimized, and self-corrected by AI.

Infographic Concept (Final Visual Summary)

“The Generative Net-Zero Pyramid”

| Level | Capability | Value |

|---|---|---|

| 🧱 1 | Data Visibility | Unified asset data & emissions mapping |

| ⚙️ 2 | Energy Optimization | Efficiency-driven control loops |

| 🌿 3 | Carbon Reduction | AI-based emission balancing |

| 🧠 4 | Autonomous Twin | Self-learning operational logic |

| 🌍 5 | Intelligent Net-Zero Ecosystem | Connected, carbon-aware enterprise |

🟢 Visual tagline:

“From Data to Decarbonization – One Digital Twin at a Time.”