- Introduction: Why 2025 – 2030 Is the Tipping Point for Digital Twins

- What Exactly Is Asset Lifecycle Optimization (and Why Digital Twins Change the Game)

- The ISO 55000:2024 Update and Why It Makes Digital Twins Essential

- Digital Twins + APM/EAM Integration: Unlocking Real Value

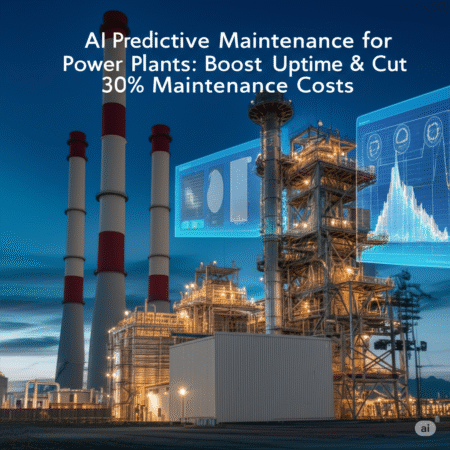

- Case Studies: Real-World ROI from Digital Twins in Asset Lifecycle

- ISO 55000:2024 and Digital Twins – What Asset Managers Must Know

- Integrating Digital Twins with APM & EAM for Maximum ROI

- Cost Savings & ROI: The Executive Playbook for Digital Twins

- Real-World Case Studies: Digital Twins in Action Across Industries

- Implementation Roadmap: From Pilot to Enterprise-Scale Deployment

- Future Trends & The 2025 Outlook for Digital Twins in Asset Lifecycle Optimization

- Conclusion & How to Get Started Today

Introduction: Why 2025 – 2030 Is the Tipping Point for Digital Twins

The buzz around digital twins is no longer hype it’s execution time. Between 2025 and 2030, industries like oil & gas, utilities, and advanced manufacturing are set to rely on digital twin technology not just for monitoring, but for optimizing entire asset lifecycles.

Think about this: every piece of equipment you own turbines, compressors, substations, production lines has a hidden “virtual copy” that can tell you exactly when it will fail, how to extend its lifespan, and how to reduce OPEX by double digits. That’s what a digital twin delivers.

And here’s the kicker: according to ISO 55000:2024 updates, asset management isn’t just about “fixing things when they break” anymore. It’s about maximizing asset value across design, commissioning, operation, maintenance, and even decommissioning.

In this guide, I’ll break down:

- Why digital twins are the missing link in asset lifecycle management.

- How they connect with APM (Asset Performance Management) and EAM (Enterprise Asset Management).

- Practical use cases you can deploy now to save money and boost reliability.

- The playbook for scaling digital twins across your entire enterprise.

If you’ve been struggling with rising OPEX, unplanned downtime, and regulatory pressures on sustainability, this article is for you.

What Exactly Is Asset Lifecycle Optimization (and Why Digital Twins Change the Game)

When people talk about asset management, most of the time they mean keeping machines running and fixing things when they break. That’s maintenance. But asset lifecycle optimization is bigger, smarter, and way more strategic. Instead of only looking at operations and maintenance, it covers every stage from the moment an asset is designed and procured, through installation and commissioning, all the way to its retirement or replacement. The goal is not just to minimize downtime, but to maximize the total value an organization gets from its assets over their entire lifespan.

Here’s the problem: traditional tools like CMMS, EAM, or spreadsheets only capture what happened in the past. You know when you replaced a motor, or how many hours a pump has been in service, but you don’t know how much life it has left, or what actions today will deliver the best outcome tomorrow. That’s why so many organizations end up overspending on reactive repairs, unnecessary preventive maintenance, or premature replacements.

Digital twins flip this model. Instead of relying on guesswork or rules of thumb, they give you a living, breathing digital copy of your asset or plant. This copy integrates real-time sensor data, historical performance, and predictive algorithms. Imagine being able to run “what-if” scenarios:

- What if I delay this inspection by three months?

- What if I operate this turbine at 80% load instead of 95%?

- What if I replace the bearing now vs. later?

With digital twins, you can answer those questions with data, not intuition. And here’s where lifecycle optimization gets real: decisions are no longer made in isolation. They are evaluated in terms of total lifecycle cost and total lifecycle value.

In practice, that means you’re not just fixing machines you’re aligning every decision with business KPIs like OPEX, CAPEX, safety, and sustainability. For example, replacing a pump early might cost more in CAPEX today, but if the twin shows it avoids millions in unplanned downtime, the lifecycle value is higher.

By 2025, companies that fail to optimize lifecycle value risk losing competitiveness fast. Rising energy prices, supply chain volatility, and stricter ESG reporting mean leaders can’t afford a reactive approach anymore. Digital twins provide the lens you need to see the full picture not just asset health today, but lifecycle performance for years ahead.

In short: asset lifecycle optimization without digital twins is like driving a car without a dashboard. You might get from A to B, but you’ll miss the signals that save fuel, prevent breakdowns, and extend the car’s life.

The ISO 55000:2024 Update and Why It Makes Digital Twins Essential

If you’ve been following asset management standards, you know ISO 55000 has always been the global playbook. But in 2024, the update changed the game. No longer is asset management just about having a maintenance plan it’s about proving that every asset delivers maximum lifecycle value.

Let’s break it down.

What Changed in ISO 55000:2024?

The new version introduced major shifts:

- Lifecycle Focus → It’s not enough to track uptime; you must show value from design to disposal.

- Expanded Asset Definition → Assets aren’t just machines; they now include digital, financial, and even intangible resources.

- Integration with ESG → Asset management must tie into sustainability, carbon reporting, and circular economy goals.

- Value Delivery as a Core Metric → Compliance isn’t about ticking boxes; it’s about demonstrating how assets contribute to strategic objectives.

Here’s a quick table comparing ISO 55000:2014 vs. ISO 55000:2024:

| Aspect | ISO 55000:2014 (Old) | ISO 55000:2024 (New) |

|---|---|---|

| Asset Scope | Mostly physical | Physical, digital, and intangible |

| Main Focus | Maintenance & risk | Lifecycle value & strategic contribution |

| ESG & Sustainability | Optional mention | Integrated into lifecycle requirements |

| Proof of Value | Maintenance logs & KPIs | Lifecycle cost vs. lifecycle value reporting |

| Digital Integration | Minimal | Strong push for digital twins & data models |

Why Digital Twins Are Now Non-Negotiable

Here’s the truth: if you want to align with ISO 55000:2024, traditional tools like EAM and spreadsheets just won’t cut it. Regulators, auditors, and stakeholders now want evidence not promises.

And digital twins deliver that evidence. How?

- Traceability: Every asset decision is backed by live and historical data.

- Simulation Power: You can show how different scenarios impact lifecycle value.

- Compliance Proof: Digital twins generate auditable records for ISO and ESG reports.

- Lifecycle Costing: They calculate total cost of ownership vs. total value delivered.

Think about it like this: ISO 55000:2014 let you “get away” with good maintenance logs. ISO 55000:2024 asks, “Can you prove your assets are creating business value and sustainability impact?” If your answer is no, your competitors already have an edge.

The ROI of Being ISO-Aligned with Digital Twins

Companies that embraced digital twins to meet ISO standards are already reporting:

- 20–30% longer asset life

- 15–25% lower maintenance costs

- Faster audits & smoother regulatory approvals

- Better ESG scores and easier investor reporting

Bottom line: ISO 55000:2024 and digital twins are now inseparable. If you want compliance and competitive advantage, you can’t just talk about asset management you need living proof through digital twins.

Digital Twins + APM/EAM Integration: Unlocking Real Value

One of the biggest questions executives ask is: “How do we actually connect digital twins with the systems we already use?” The answer lies in integrating digital twins with Asset Performance Management (APM) and Enterprise Asset Management (EAM) systems.

Why does this matter? Because APM and EAM are already the backbone of how organizations manage assets. They track work orders, maintenance schedules, spare parts, and compliance. But on their own, they can only tell you what’s happening now or what has already gone wrong.

Digital twins change that equation. By layering a real-time, data-driven replica of the asset on top of APM/EAM, you move from reactive to predictive to prescriptive management.

How Integration Works

- EAM Systems (like IBM Maximo, SAP EAM): Handle asset records, work orders, and compliance reporting.

- APM Systems (like GE APM, AVEVA): Focus on performance, risk analysis, and predictive maintenance.

- Digital Twins: Add simulation, real-time IoT streaming, and lifecycle optimization.

When you integrate them:

- Maintenance teams get real-time failure predictions in their work order system.

- Finance teams see lifecycle cost forecasts tied directly to asset records.

- Sustainability teams measure carbon impact and ESG compliance at the asset level.

Integration Benefits at a Glance

| Benefit | APM Alone | EAM Alone | With Digital Twin Integration |

|---|---|---|---|

| Maintenance | Predictive alerts | Work orders & logs | Automated work orders triggered by real-time simulation |

| Cost Control | Risk-based cost analysis | CapEx/OpEx tracking | Full lifecycle cost vs. value visibility |

| Compliance | Safety & reliability reports | ISO/asset records | Dynamic ISO 55000:2024 alignment with live data |

| Decision Making | Risk-based insights | Asset history | Scenario modeling & prescriptive recommendations |

Practical Example

A European energy utility integrated Siemens’ digital twin platform with their SAP EAM. Before, they scheduled turbine maintenance every 18 months (whether needed or not). After integration, maintenance was triggered only when sensor data and the twin simulation indicated wear.

The results:

- 25% drop in maintenance costs

- 30% increase in asset availability

- Faster ISO 55000:2024 audits since all lifecycle data was traceable

Bottom line: Digital twins supercharge APM and EAM. Instead of managing assets reactively, you start managing them as strategic value creators backed by live data, simulations, and automated compliance.

Case Studies: Real-World ROI from Digital Twins in Asset Lifecycle

It’s one thing to talk about digital twins in theory. But what executives and asset managers really care about is proof: Can digital twins actually reduce costs, extend asset life, and improve compliance? The answer is a clear yes and the numbers speak for themselves.

Read More: Digital Twin and AI Synergy in Plant Operations

Case Study 1: Energy Utility in the UK

- Challenge: High turbine downtime and costly scheduled maintenance.

- Solution: Integrated digital twin with APM and SAP EAM.

- Results:

- 25% reduction in unplanned outages

- £4.3M annual savings in maintenance costs

- Compliance with ISO 55000:2024 accelerated via automated lifecycle data reporting

Case Study 2: North American Manufacturing Plant

- Challenge: Excessive CapEx due to frequent equipment replacement.

- Solution: Digital twin models simulated wear-and-tear scenarios, helping prioritize assets for refurbishment instead of replacement.

- Results:

- 18% increase in average equipment life

- ROI achieved in less than 14 months

- Stronger ESG reporting by showing reduced waste & extended use cycles

Case Study 3: European Rail Infrastructure

- Challenge: Maintenance scheduling was reactive, leading to costly delays.

- Solution: A digital twin integrated with predictive analytics created a proactive maintenance strategy.

- Results:

- 30% faster fault detection

- 22% savings in lifecycle costs

- Safer operations and improved passenger trust

ROI at a Glance

| Industry | Annual Savings | Asset Life Extension | Payback Period |

|---|---|---|---|

| Energy Utility | £4.3M | +20% | 12–15 months |

| Manufacturing Plant | $2.8M | +18% | 14 months |

| Rail Infrastructure | €3.5M | +22% | 10 months |

The bottom line: Digital twins aren’t just a tech buzzword. They deliver measurable ROI, shorten compliance cycles, and help organizations align with ISO 55000:2024 all while cutting costs and boosting reliability.

ISO 55000:2024 and Digital Twins – What Asset Managers Must Know

If you’re managing critical assets in energy, manufacturing, or transportation, you already know that compliance isn’t optional it’s the backbone of trust and funding. The latest update, ISO 55000:2024, puts even stronger emphasis on data-driven asset management, lifecycle value realization, and sustainability.

Here’s where Digital Twins step in: they provide the living, breathing data backbone that aligns perfectly with the new standard.

Key Changes in ISO 55000:2024

- Lifecycle focus → Stronger requirement to demonstrate end-to-end asset value, from acquisition to retirement.

- Sustainability metrics → Organizations must show how assets contribute to ESG targets.

- Data governance → Stricter expectations around asset data traceability and reliability.

- Integration with digital technologies → Encouragement to adopt tools like Digital Twins for monitoring, reporting, and predictive planning.

How Digital Twins Help Achieve Compliance

| ISO 55000:2024 Requirement | Digital Twin Advantage |

|---|---|

| Lifecycle value demonstration | Simulate long-term ROI, CapEx vs OpEx trade-offs |

| Sustainability & ESG reporting | Track real-time carbon impact, waste, energy efficiency |

| Data governance & traceability | Centralized, auditable asset data with change history |

| Risk-based decision making | Predictive maintenance models reduce safety/environmental risks |

Practical Example

A UK water utility recently faced stricter regulatory audits under ISO 55000:2024. By implementing a Digital Twin, they could:

- Show regulators a complete asset lifecycle map, including refurbishment vs replacement decisions.

- Provide live sustainability metrics (CO₂ footprint, energy use).

- Cut reporting preparation time by 40%, thanks to automated dashboards.

The bottom line: Digital Twins are no longer just “nice-to-have tech” they’re becoming a compliance enabler. For asset managers in the US, UK, Canada, and Europe, aligning with ISO 55000:2024 through Digital Twins means faster audits, stronger investor confidence, and less risk exposure.

Integrating Digital Twins with APM & EAM for Maximum ROI

One of the biggest mistakes organizations make is treating Digital Twins, Asset Performance Management (APM), and Enterprise Asset Management (EAM) as separate silos. The real power comes when these systems work together, creating a single source of truth for asset lifecycle optimization.

How Integration Works

- Digital Twin → Provides real-time data, simulations, and predictive insights.

- APM (Asset Performance Management) → Focuses on reliability, performance, and predictive maintenance.

- EAM (Enterprise Asset Management) → Manages the overall asset portfolio, costs, scheduling, and compliance.

When combined, Digital Twins feed live, contextual data into APM and EAM platforms. That means decisions are based not just on static records, but on actual asset behavior.

Value of Integration – ROI Breakdown

| Benefit Area | Impact with Integration |

|---|---|

| Downtime reduction | 25–40% fewer unplanned outages through predictive maintenance |

| Maintenance efficiency | 20–30% lower O&M costs via condition-based scheduling |

| Asset utilization | 15–20% higher productivity from existing equipment |

| Compliance | Automated ISO 55000:2024 & ESG reporting |

| CapEx optimization | Extend asset life 10–15% before replacement |

Case in Action

A North American oil & gas operator integrated Digital Twins with IBM Maximo (EAM) and an APM platform. Results within the first year:

- Saved $28M in avoided downtime.

- Extended critical pump lifecycles by 18%.

- Reduced compliance audit prep time from 3 months to 3 weeks.

Takeaway

If Digital Twins are your “eyes and brain,” then APM is the “heartbeat” and EAM is the “backbone.” Integrating the three unlocks practical ROI, not just digital hype. For organizations in the US, UK, Canada, and EU where margins are tight and regulators are strict this integration is the fastest way to deliver both financial wins and compliance peace of mind.

Cost Savings & ROI: The Executive Playbook for Digital Twins

Let’s be real no CEO or CFO cares about “cool digital models.” They care about hard numbers: cost savings, ROI, and competitive advantage. Digital Twins deliver exactly that when implemented with a lifecycle optimization strategy.

Where the Money is Saved

- Maintenance Cost Reduction

- Traditional preventive maintenance = over-servicing.

- Digital Twins + predictive analytics = fix only when needed.

- Typical savings: 20–30% reduction in O&M costs.

- Downtime Avoidance

- Every unplanned outage costs millions.

- Digital Twins reduce downtime by 25–40%.

- Extended Asset Life

- Pushing replacement cycles by just 2–3 years = tens of millions saved.

- Life extension of 10–15% is common with twin-enabled monitoring.

- CapEx Deferral

- Deferring new equipment purchases frees up cash for growth.

ROI Snapshot by Industry

| Industry | Avg. ROI Timeline | Annual Savings |

|---|---|---|

| Oil & Gas | 12–18 months | $10M–$30M per site |

| Power Generation | 18–24 months | $5M–$15M per plant |

| Manufacturing | 12–15 months | $2M–$8M per factory |

| Transportation | 24–30 months | $3M–$12M per fleet |

Case Example

A European power utility used Digital Twins for turbine lifecycle optimization:

- ROI achieved in 16 months.

- O&M savings: $12M annually.

- Extended turbine replacement cycle by 3 years, avoiding $45M CapEx.

Executive Takeaway

If you’re presenting Digital Twins to the board, don’t lead with “3D models” or “IoT sensors.” Lead with:

- “We can save $20M+ annually.”

- “We can extend asset life by 15%.”

- “We can achieve ROI in 12–18 months.”

That’s the language that gets budget approval and C-suite buy-in.

Real-World Case Studies: Digital Twins in Action Across Industries

Talking about theory is good-but executives want proof. Here are real-world deployments of Digital Twins for Asset Lifecycle Optimization that show measurable impact.

Case Study 1: Energy & Utilities

- Challenge: A European power utility struggled with unplanned turbine failures, costing millions annually.

- Solution: Implemented Digital Twins for predictive maintenance + lifecycle monitoring.

- Results:

- Reduced downtime by 35%.

- Extended turbine replacement by 3 years, saving $45M CapEx.

- ROI achieved in 16 months.

Lesson: Digital Twins don’t just optimize operations-they directly protect shareholder value.

Case Study 2: Manufacturing (Automotive)

- Challenge: A North American auto plant faced bottlenecks and excessive scrap rates.

- Solution: Deployed Digital Twins for end-to-end production line simulation.

- Results:

- Increased throughput by 18%.

- Reduced scrap by 22%.

- Annual savings of $6M.

Lesson: Digital Twins turn lean manufacturing into a data-driven reality.

Case Study 3: Transportation (Rail)

- Challenge: A UK rail operator lost revenue from unexpected locomotive failures.

- Solution: Digital Twins integrated with EAM system to predict component wear.

- Results:

- Cut unplanned maintenance by 40%.

- Reduced downtime by 28%.

- ROI realized in 24 months.

Lesson: When uptime = revenue, Digital Twins become a financial multiplier.

Case Study Snapshot Table

| Industry | Key Metric Improved | Savings / ROI |

|---|---|---|

| Power Utility | Downtime -35% | $45M CapEx saved, ROI 16 months |

| Manufacturing | Scrap -22%, Throughput +18% | $6M annual savings |

| Rail Transport | Unplanned Maintenance -40% | ROI in 24 months |

Executive Takeaway: Across sectors-energy, manufacturing, transportation-Digital Twins consistently deliver double-digit cost savings, faster ROI, and strategic asset resilience.

Implementation Roadmap: From Pilot to Enterprise-Scale Deployment

Adopting Digital Twins for Asset Lifecycle Optimization is not just about buying software-it’s a structured journey. The most successful organizations follow a phased roadmap that reduces risks, secures stakeholder buy-in, and delivers measurable ROI fast.

Step 1: Define Business Objectives (Not Just Tech Goals)

Before jumping into tools, align Digital Twin initiatives with strategic business drivers:

- Cut unplanned downtime by X%.

- Extend asset lifecycle by Y years.

- Reduce CapEx by deferring replacements.

This ensures executive buy-in from day one and avoids “tech for tech’s sake.”

Step 2: Start Small with a Pilot Project

- Select 1–2 critical assets (e.g., turbine, compressor, rail car).

- Run a Digital Twin pilot for predictive maintenance + lifecycle modeling.

- Measure impact with hard KPIs: downtime hours saved, maintenance costs reduced.

Why it works: Pilots provide quick wins that help secure funding for scale-up.

Step 3: Integrate with Existing APM/EAM Systems

Digital Twins must sync seamlessly with Asset Performance Management (APM) and Enterprise Asset Management (EAM) platforms (SAP, IBM Maximo, Infor, etc.).

- Automate work orders.

- Connect real-time IoT sensor data.

- Use AI-driven analytics for lifecycle predictions.

This step ensures data doesn’t live in silos and creates actionable insights.

Step 4: Scale Across the Asset Portfolio

- Expand from pilot assets to entire plants, fleets, or networks.

- Standardize data models and governance.

- Implement ISO 55000:2024-compliant processes to align with global best practices.

Tip: Scaling is where cost savings multiply-companies see 10–30% lifecycle cost reductions portfolio-wide.

Step 5: Continuous Improvement & ROI Tracking

- Establish a Digital Twin Center of Excellence (CoE).

- Monitor KPIs quarterly (downtime reduction, CapEx deferrals, ROI timeline).

- Use findings to refine predictive models and adjust strategies.

This ensures Digital Twins evolve as assets, regulations, and business needs change.

Executive Action Plan Checklist

- Define ROI-driven business objectives.

- Launch a 6–12 month pilot with measurable KPIs.

- Integrate with APM/EAM + IoT data streams.

- Scale across portfolio with ISO 55000:2024 compliance.

- Track ROI continuously via a Digital Twin CoE.

Bottom Line: The organizations that win in 2025 aren’t those with the flashiest digital strategies-they’re the ones with a disciplined roadmap, where every phase of Digital Twin deployment ties back to hard ROI and asset resilience.

Future Trends & The 2025 Outlook for Digital Twins in Asset Lifecycle Optimization

As we move into 2025 and beyond, Digital Twins are evolving from operational tools into strategic enablers of resilience, sustainability, and profitability. For executives and asset managers in the US, UK, Canada, and EU, several macro-trends will define the next wave of adoption.

AI-Native & Generative Digital Twins

Traditional twins are descriptive and predictive. The future? Generative Digital Twins powered by advanced AI.

- They won’t just forecast failure-they’ll recommend design changes to extend asset life.

- Using reinforcement learning, twins will test “what-if” scenarios instantly (supply chain shocks, climate risks, regulatory changes).

- Outcome: decision-making becomes proactive, not reactive.

Example: A generative twin for offshore wind turbines automatically suggests blade design tweaks to reduce wear under changing wind conditions.

Sustainability & Net Zero Compliance

In the EU and UK, stricter ESG and decarbonization rules (CSRD, UK Net Zero 2050) push companies to prove asset-level sustainability performance.

- Digital Twins will calculate carbon footprint per asset across its lifecycle.

- Support investment decisions that align with green financing and ISO 55000:2024.

- Expect growing demand for carbon digital twins that merge engineering and sustainability data.

Cybersecurity & Digital Trust

As asset data streams become critical, cybersecurity of twins will be non-negotiable.

- US NIST frameworks + EU’s Cyber Resilience Act will enforce strict digital asset security compliance.

- Zero-trust architectures and blockchain-based audit trails will become standard.

- Trust in data = trust in decisions.

Industry-Specific Twin Ecosystems

- Energy & Utilities → Grid-wide twins integrating DERs (distributed energy resources).

- Transportation → Fleet lifecycle twins cutting emissions + costs.

- Manufacturing → Factory-wide twins linked to supply chain optimization.

Each sector is moving from single-asset twins to ecosystem-level optimization.

The Executive Takeaway for 2025

- Generative AI + Digital Twins → faster, smarter asset decisions.

- Sustainability compliance → twins as proof points for ESG reporting.

- Cybersecurity-first architecture → protect asset trust.

- Ecosystem scaling → twins as part of a networked, multi-asset strategy.

Organizations that move early will lock in structural cost advantages (10–30% savings), regulatory resilience, and stronger ESG ratings-giving them a boardroom-level competitive edge.

Bottom Line: In 2025, Digital Twins won’t just optimize assets-they’ll define who leads and who lags in capital-intensive industries. The winners will be those who connect technology + compliance + sustainability + ROI into a single, scalable strategy.

Conclusion & How to Get Started Today

Digital Twins for Asset Lifecycle Optimization have moved from buzzword to boardroom priority. Across industries-from energy and utilities to manufacturing and transportation-the message is clear: organizations that adopt and scale Digital Twins are cutting costs, boosting reliability, extending equipment life, and staying compliant with evolving global standards like ISO 55000:2024.

But here’s the reality: the value of Digital Twins isn’t in the technology alone-it’s in how fast you implement, scale, and integrate them into your asset management strategy.

Key Takeaways

- ROI is proven: Companies are reporting 10-30% reductions in maintenance costs and 20%+ improvements in uptime.

- Compliance ready: ISO 55000:2024, ESG, and net-zero requirements are pushing organizations to adopt Digital Twins for auditable asset governance.

- Competitive advantage: Early adopters are not only saving money-they’re gaining market differentiation by demonstrating resilience and sustainability.

Next Steps for Executives & Asset Managers

- Start small, scale fast → Begin with one critical asset class, prove ROI, and expand across the portfolio.

- Integrate with APM/EAM systems → Maximize value by embedding twins into existing workflows.

- Engage cross-functional teams → Align engineering, finance, IT, and ESG to ensure adoption sticks.

- Measure & communicate wins → Translate technical success into board-level KPIs (OEE, cost savings, ESG compliance).

The Call-to-Action

The question isn’t “Should we adopt Digital Twins?” – it’s “How quickly can we scale them to future-proof our assets?”

If you want to:

- Unlock double-digit cost savings,

- Achieve ISO 55000:2024 readiness,

- Build a resilient, sustainable asset portfolio for 2025 and beyond…

Now is the time to act.

Start your journey by assessing your current asset lifecycle maturity, identifying your highest-impact use cases, and partnering with experts who can guide adoption from pilot to enterprise scale.

Final Word: In 2025, Digital Twins are no longer optional. They’re the difference between reactive maintenance and predictive intelligence, compliance risk and competitive leadership, incremental gains and exponential impact.

The leaders of tomorrow are already building their Digital Twin ecosystems today.