- Introduction

- Understanding Digital Twin Technology

- AI in Industrial Plant Operations

- Synergy Between Digital Twin and AI

- Predictive Maintenance Powered by Digital Twin + AI

- Energy Optimization and Emissions Reduction

- Operational Decision-Making and Process Control

- Safety Management and Risk Mitigation

- Case Studies of Digital Twin + AI in Industry

- Implementation Strategies for Plant Managers

- Overcoming Common Challenges

- Future Trends in Digital Twin and AI for Plants

- Measuring ROI and Success Metrics

- Preparing Your Plant for Digital Twin + AI

- Conclusion

Introduction

If you’re running an industrial plant in 2025, chances are you’ve heard about Digital Twins and Artificial Intelligence (AI). But here’s the thing: knowing about them isn’t enough. To really transform your operations, you need to understand how these two powerful technologies work together, creating a synergy that can boost efficiency, reduce downtime, and improve safety.

A Digital Twin is essentially a virtual replica of a physical asset, process, or entire system. Imagine having a digital model of your plant that updates in real time, reflecting every pump, valve, and turbine’s condition. Now, add AI into the mix. AI doesn’t just observe it analyzes patterns, predicts failures, and provides actionable recommendations. Together, they turn mountains of raw data into insights you can actually use.

Let’s talk about why this matters. Traditional operations rely on reactive maintenance fixing things after they break or preventive maintenance based on schedules. Both approaches are costly and inefficient. With Digital Twin and AI synergy, you can predict exactly when equipment will need service, avoid unplanned downtime, and extend the life of critical assets. That’s not just operational efficiency it’s real money saved.

But it’s not only about maintenance. Energy costs and environmental compliance are huge pain points for modern plants. AI can analyze your Digital Twin data to spot inefficiencies, optimize processes, and even reduce carbon emissions. The result? Smarter, greener operations without compromising output.

Safety is another area where this synergy shines. Digital Twins can simulate dangerous scenarios while AI predicts the likelihood and impact of potential incidents. You get proactive safety management, protecting both personnel and equipment, and staying ahead of regulatory requirements.

Throughout this article, we’ll explore how Digital Twin and AI synergy redefines plant operations. From predictive maintenance and energy optimization to operational decision-making and safety management, you’ll see real-world examples, practical insights, and strategies you can implement immediately.

By the end, you’ll understand not just the technology, but how to leverage it to stay competitive in 2025 and beyond. If you want your plant to operate smarter, safer, and more efficiently, this is the roadmap you’ve been waiting for.

Understanding Digital Twin Technology

If you’ve been in plant operations for a while, you know one thing: what you can’t see, you can’t control. That’s exactly why Digital Twin technology has become a game-changer in 2025. At its core, a Digital Twin is a virtual replica of a physical asset, process, or even an entire plant, constantly updated with real-time data from sensors, SCADA systems, IoT devices, and historical databases. Think of it as your plant’s digital shadow but one that talks, learns, and predicts.

There are three main types of Digital Twins you need to know:

- Asset-level Twins – Focus on individual equipment like pumps, compressors, or turbines. They track operational parameters and predict maintenance needs.

- Process-level Twins – Simulate workflows or production lines, highlighting bottlenecks, inefficiencies, and optimization opportunities.

- System-level Twins – Provide a bird’s-eye view of the entire plant, integrating assets, processes, and operations into a single, actionable model.

Here’s why it matters: Digital Twins allow you to simulate scenarios before touching the real equipment. Want to see how a temperature increase affects your reactor? Or test how load variations impact your turbine efficiency? Your Digital Twin can model it all virtually, without risk.

But the real magic happens when you feed these models with accurate, real-time data. Sensors track vibration, pressure, temperature, and flow. SCADA systems provide control insights. Historical records give context. All this data creates a high-fidelity model that reflects your plant’s true behavior.

Digital Twins also provide decision support. For instance, you can forecast energy usage, predict equipment wear, or simulate emergency scenarios all from your digital model. Operators gain situational awareness like never before, enabling smarter, faster, and safer decisions.

In short, a Digital Twin isn’t just a fancy visualization tool it’s the backbone of a modern, intelligent plant. Alone, it’s powerful; paired with AI, it becomes a predictive engine that can redefine efficiency, safety, and operational excellence.

AI in Industrial Plant Operations

Let’s be real: industrial plants generate massive amounts of data every second. Pumps, compressors, turbines, reactors they’re all sending streams of information about temperature, pressure, vibration, and flow. The question is: how do you turn that raw data into decisions that actually matter? That’s where Artificial Intelligence (AI) comes in.

AI acts like the brain behind the plant’s operations, analyzing patterns, predicting equipment failures, and optimizing processes. It’s not science fiction it’s happening right now in leading plants around the world. Here’s what AI brings to the table:

- Predictive Maintenance – AI evaluates sensor data and historical performance to forecast equipment failures. Instead of waiting for a pump to fail or relying on rigid schedules, you can act proactively, avoiding costly downtime.

- Process Optimization – AI continuously analyzes process parameters, recommending tweaks that improve efficiency, reduce energy consumption, and cut operational costs.

- Anomaly Detection – Subtle irregularities in equipment behavior can signal bigger problems. AI detects these anomalies early, giving you the chance to intervene before issues escalate.

- Operational Forecasting – By analyzing historical trends, AI predicts production bottlenecks, resource needs, and demand fluctuations, helping managers plan smarter.

Now, here’s where it gets interesting: AI and Digital Twins work best together. A Digital Twin provides a live virtual model of your plant, and AI interprets the data flowing into that model. The result? You don’t just see problems you predict them and simulate solutions. For example, an AI algorithm can test multiple operational scenarios on a Digital Twin, showing which process adjustments maximize output while minimizing energy use.

Industrial plants are already seeing tangible benefits: fewer unplanned shutdowns, extended equipment life, improved safety, and measurable energy savings. But the real win is decision-making confidence. With AI analyzing your Digital Twin data, operators and managers aren’t guessing they’re acting on insights backed by real-time, predictive intelligence.

In short, AI transforms data into actionable insight, making your plant smarter, safer, and more efficient. And when paired with a Digital Twin, it creates a predictive, proactive ecosystem that can redefine how industrial operations are managed in 2025 and beyond.

Synergy Between Digital Twin and AI

Here’s the truth: a Digital Twin or AI on its own is powerful, but together, they’re unstoppable. Think of a Digital Twin as the virtual body of your plant and AI as the brain that analyzes, predicts, and guides action. When combined, they create a self-learning ecosystem that continuously improves operational efficiency, safety, and decision-making.

Let’s break it down. A Digital Twin mirrors your plant in real time pumps, compressors, turbines, pipelines, even full production lines. It collects massive streams of data: temperatures, pressures, flow rates, vibration, and more. AI takes this data and discovers patterns, predicts failures, and recommends actions. The two technologies feed off each other: the Digital Twin provides context, and AI provides intelligence.

For example, in an oil & gas plant, a turbine’s Digital Twin might simulate stress under high-load conditions. AI analyzes the simulation along with historical performance data and predicts that a specific turbine blade may fail in three weeks. Maintenance teams can preemptively replace the blade, avoiding costly unplanned downtime. That’s a perfect example of proactive decision-making powered by synergy.

The synergy doesn’t stop at maintenance. It extends to process optimization and energy management. AI can run thousands of virtual scenarios on the Digital Twin to identify the most efficient operational settings. The result? Reduced energy consumption, lower emissions, and higher production efficiency all without experimenting on the actual plant.

Safety and risk management also benefit massively. Digital Twins can simulate hazardous events, such as chemical leaks or equipment overloads. AI evaluates the likelihood and potential impact of these events, enabling operators to take preventive measures. Instead of reacting to incidents, plants anticipate and mitigate risks, protecting personnel and ensuring regulatory compliance.

In essence, the synergy between Digital Twin and AI transforms industrial operations from reactive to predictive, and from manual to intelligent. Operators gain real-time insight, predictive foresight, and actionable recommendations all in one ecosystem. This combination isn’t just a tech upgrade; it’s a strategic advantage that can redefine how plants operate in 2025 and beyond.

Predictive Maintenance Powered by Digital Twin + AI

Let’s face it: downtime is the silent killer in plant operations. Every unplanned shutdown costs money, disrupts schedules, and can even jeopardize safety. Traditional maintenance whether reactive or schedule-based just doesn’t cut it anymore. That’s why predictive maintenance powered by Digital Twin and AI has become a must-have in 2025.

Here’s how it works. Your Digital Twin continuously mirrors the real-time condition of critical equipment: pumps, compressors, turbines, reactors you name it. Sensors feed data on vibration, temperature, pressure, and flow into the digital model. Then AI steps in, analyzing the data for patterns that indicate potential failures. It doesn’t just tell you something might break; it tells you what, why, and when it’s likely to happen.

Take an oil & gas refinery for example. A pump’s Digital Twin may detect subtle vibration changes that aren’t noticeable in real life. AI evaluates these signals against historical failure data and predicts that the pump could fail within two weeks. Maintenance can be scheduled precisely, avoiding unplanned downtime and costly repairs. No guesswork, no wasted resources.

But the benefits don’t stop at reliability. Predictive maintenance optimizes spare parts inventory, reduces unnecessary maintenance, and extends equipment life. Safety is also improved, because the risk of catastrophic failures is minimized. Operators can focus on high-value tasks rather than constant firefighting.

The synergy creates a closed-loop system. Predictions guide maintenance actions, outcomes are monitored in real time, and the Digital Twin updates continuously to refine future forecasts. Over time, the system learns and becomes smarter, improving accuracy and operational efficiency.

In short, predictive maintenance powered by Digital Twin and AI is not just about avoiding downtime it’s about maximizing asset performance, reducing costs, and enabling smarter operational decisions. If your plant isn’t leveraging this synergy yet, you’re leaving money and reliability on the table.

Energy Optimization and Emissions Reduction

Energy costs and environmental compliance are two of the biggest challenges facing industrial plants today. Every inefficiency eats into your bottom line, and failing to meet emissions standards can lead to hefty fines and reputational damage. That’s where the Digital Twin and AI synergy becomes a game-changer.

Here’s the deal: a Digital Twin maps your entire plant in real time, showing energy flows, equipment efficiency, and process dynamics. AI then analyzes this data to identify inefficiencies and recommend actionable adjustments. Imagine knowing exactly which pump, compressor, or boiler is wasting energy and how to fix it without touching a single valve. That’s precision energy management at its best.

Take a chemical processing plant as an example. The Digital Twin simulates heat exchangers, reactors, and distillation columns, while AI evaluates thousands of operational scenarios. It may reveal that adjusting a reactor’s temperature by just 2°C increases yield while cutting energy consumption by 5%. Implementing this change in the real plant can save thousands of dollars monthly and significantly reduce carbon emissions.

Beyond efficiency, AI-driven Digital Twins also support regulatory compliance. By continuously monitoring emissions, energy usage, and process parameters, the system can predict potential breaches before they occur. Operators can take proactive action, avoiding fines and ensuring sustainability targets are met.

The benefits compound over time. AI learns from historical and real-time data, refining its recommendations and driving continuous improvement. Plants that embrace this synergy see measurable reductions in energy costs, optimized equipment scheduling, and a smaller environmental footprint all without sacrificing production.

In short, Digital Twin + AI doesn’t just make operations smarter it makes them leaner, greener, and more profitable. If you want your plant to stay competitive in 2025, ignoring this synergy isn’t an option. It’s the roadmap to sustainable efficiency and operational excellence.

Operational Decision-Making and Process Control

If you’ve ever felt like running a plant is a constant game of reactive firefighting, you’re not alone. Traditional operational decision-making often relies on delayed reports, manual inspections, or gut feeling. That’s exactly why the Digital Twin and AI synergy is such a game-changer it gives operators real-time insight and predictive foresight to make smarter decisions.

Here’s how it works: your Digital Twin acts as a mirror of the plant, showing live status of equipment, process flows, and environmental conditions. AI then analyzes this data, predicts potential bottlenecks, and suggests optimal operational strategies. The result? Decisions are no longer reactive they’re data-driven, timely, and precise.

For example, consider a refinery managing multiple crude distillation units. A Digital Twin can simulate various feedstock blends, while AI evaluates which combination maximizes yield, minimizes energy consumption, and reduces risk of equipment stress. Operators can implement these recommendations confidently, knowing they’ve been validated virtually.

This synergy also improves process control. AI can detect subtle deviations from normal operation that human eyes might miss. For instance, a small vibration anomaly in a compressor may signal impending failure. The system alerts operators and recommends corrective actions, preventing unplanned downtime and ensuring continuous, efficient operation.

Moreover, operational planning becomes far more strategic and proactive. AI can forecast production capacity, energy needs, and maintenance windows, allowing plant managers to schedule shifts, resources, and inventories more effectively. This reduces costs, improves throughput, and ensures smoother plant performance.

In short, combining Digital Twin and AI transforms decision-making from guesswork into a scientific, data-driven process. Operators gain the confidence to act decisively, optimize processes in real time, and maintain peak performance. In 2025, this isn’t just a competitive advantage it’s essential for survival in the modern industrial landscape.

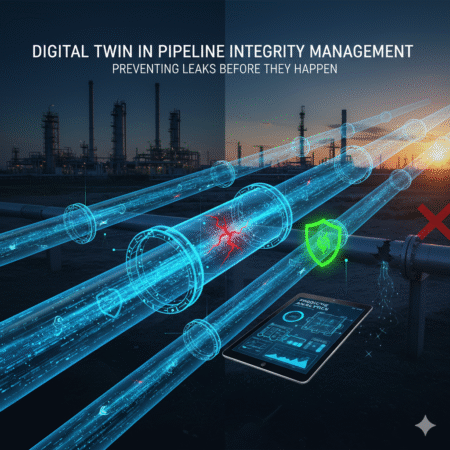

Safety Management and Risk Mitigation

Safety in industrial plants isn’t optional it’s a non-negotiable priority. Yet, traditional safety strategies often rely on reactive measures: responding after an incident occurs or performing routine checks that may miss subtle risks. This is where the Digital Twin and AI synergy fundamentally changes the game.

A Digital Twin allows you to simulate hazardous scenarios virtually. Think of it as a digital sandbox where you can test what happens if a pump fails, a valve leaks, or a pressure spike occurs. AI steps in to analyze these simulations, predict the likelihood and potential impact of each scenario, and recommend preventive actions. The combination ensures you’re not guessing you’re planning proactively.

Consider an oil & gas facility handling flammable gases. A Digital Twin models all equipment and pipelines, tracking pressure, temperature, and flow in real time. AI evaluates the data to detect anomalies like subtle pressure fluctuations in a compressor that may indicate a leak. Maintenance and operations teams are alerted before a minor issue escalates into a major incident, significantly reducing risk to personnel and the environment.

Beyond equipment failures, this synergy also improves compliance with safety regulations. Many industrial standards, including OSHA and ISO, require continuous monitoring and risk assessment. With a Digital Twin + AI system, you have a living record of simulated and real-time safety scenarios, giving you audit-ready insights and ensuring regulatory adherence.

Moreover, training benefits immensely. Operators can interact with Digital Twin simulations to practice emergency responses without putting real assets or people at risk. AI enhances these scenarios by dynamically adjusting variables based on real-world data, creating realistic and continuously evolving training exercises.

In short, Digital Twin and AI transform safety management from reactive to predictive. Plants can anticipate incidents, optimize preventive measures, and protect personnel and assets. In today’s competitive and regulated industrial landscape, this synergy isn’t just an advantage it’s critical for sustainable and safe operations.

Case Studies of Digital Twin + AI in Industry

Seeing is believing. To truly understand the power of Digital Twin and AI synergy, let’s look at real-world examples where plants have transformed operations, cut costs, and improved safety.

Read More: Digital Twin Jobs & Future Careers (2025–2030): Skills, Salaries & How to Break In

Oil & Gas Refinery in the US

A large refinery integrated Digital Twins for its compressors and turbines with AI-based predictive maintenance. Within six months, unplanned downtime dropped by 30%, while maintenance costs decreased by 15%. AI analyzed vibration and temperature patterns from Digital Twins, predicting failures before they occurred, allowing maintenance teams to act proactively rather than reactively.

Chemical Manufacturing Plant in Germany

This plant used a Digital Twin to simulate chemical reactors and AI to optimize process parameters. By testing multiple virtual scenarios, AI identified the optimal temperature and pressure settings that maximized output while reducing energy consumption by 7%. The synergy also helped predict potential safety hazards, ensuring compliance with strict EU regulations.

Power Generation Facility in Japan

A thermal power plant integrated Digital Twin modeling of turbines and AI-driven energy optimization. AI analyzed real-time operational data and suggested adjustments that improved turbine efficiency by 5%, reduced fuel consumption, and cut CO₂ emissions significantly. The system also predicted maintenance needs, preventing unexpected shutdowns.

Key Takeaways from These Case Studies:

- Predictive Maintenance Works: AI + Digital Twin reduces downtime and saves costs.

- Process Optimization is Measurable: Simulation-driven adjustments improve efficiency and output.

- Safety and Compliance are Enhanced: Risks are identified virtually before real-world impact.

- Energy and Emissions Benefits are Real: Plants save money while meeting sustainability targets.

These examples demonstrate that the synergy isn’t theoretical it’s actionable and profitable. Companies investing in Digital Twin and AI are not just keeping up; they’re setting the standard for modern industrial operations.

By analyzing these case studies, it’s clear: if your plant isn’t leveraging this synergy yet, you’re leaving efficiency, safety, and profitability on the table.

Implementation Strategies for Plant Managers

So, you’re convinced: Digital Twin and AI synergy can transform your plant operations. But how do you actually implement it without disrupting ongoing production? Let’s break it down into actionable strategies that any plant manager can follow.

- Start Small, Scale Fast

Don’t try to digitalize your entire plant at once. Begin with a critical asset or process, such as a key compressor or turbine line. Build a Digital Twin for this segment, integrate AI for predictive insights, and measure results. Once you see tangible ROI, expand gradually across other systems. - Invest in Data Quality

Digital Twins and AI rely on accurate data. Ensure your sensors, IoT devices, and SCADA systems provide reliable, real-time information. Garbage in, garbage out without quality data, predictions and recommendations won’t be trustworthy. - Cross-Functional Collaboration

Successful implementation isn’t just a tech project it’s an organizational change. Operations, maintenance, safety, and IT teams need to collaborate closely. AI might suggest an adjustment, but operations must verify feasibility, maintenance must plan interventions, and IT ensures data integrity. - Integrate with Existing Systems

Your Digital Twin and AI solutions should complement not replace existing systems. Integrate with ERP, CMMS, and SCADA platforms to maximize visibility and streamline workflows. This reduces friction and helps teams adopt the technology faster. - Continuous Learning and Feedback Loops

Digital Twin + AI is not static. As equipment ages and processes evolve, the system learns and adapts, improving prediction accuracy and operational insights. Establish feedback loops where outcomes inform future AI recommendations. - Focus on Quick Wins

Identify areas where immediate ROI is achievable, such as predictive maintenance for high-value equipment or energy optimization in critical processes. Demonstrating early success builds confidence and secures executive support. - Plan for Training

Operators and managers must understand how to interpret AI insights and interact with Digital Twins. Invest in hands-on training and scenario simulations to ensure teams can act on recommendations effectively.

By following these strategies, plant managers can implement Digital Twin and AI synergy smoothly, confidently, and profitably. The key is to approach it strategically: start small, ensure quality, collaborate, integrate, and scale intelligently.

Overcoming Common Challenges

Implementing Digital Twin and AI synergy sounds amazing on paper but let’s be honest, it’s not without challenges. Many plant managers hesitate because of perceived complexity, costs, or technology adoption hurdles. The good news? These challenges can be overcome with the right approach.

- Data Overload

Industrial plants generate massive amounts of data, and it’s easy to feel overwhelmed. The solution? Focus on high-value data streams first critical equipment, key processes, and safety parameters. Use AI to filter and analyze relevant data, turning raw information into actionable insights without drowning your team in numbers. - Integration Complexity

Your plant probably has existing SCADA, ERP, and CMMS systems. Integrating Digital Twins and AI can feel daunting. The key is phased integration: start with one system or asset, ensure smooth connectivity, and expand gradually. Prioritize systems that will yield the fastest ROI to build confidence and momentum. - Change Management and Adoption

Technology adoption is as much about people as it is about machines. Operators may resist new tools if they don’t understand the benefits. Address this with hands-on training, clear communication, and quick wins. Show teams how AI insights and Digital Twins make their work easier, safer, and more efficient. - Upfront Costs

Yes, implementing Digital Twin and AI involves investment. But consider it an investment, not an expense. Start small on critical assets to demonstrate ROI through reduced downtime, energy savings, and predictive maintenance. Once success is visible, scaling becomes easier and less risky. - Ensuring Accuracy

AI predictions are only as good as the data fed into the Digital Twin. Inaccurate sensor readings or outdated models can compromise reliability. Regular calibration, validation, and continuous feedback loops ensure accuracy and trustworthiness of insights. - Cybersecurity Concerns

Connected systems increase exposure to cyber threats. Protect your Digital Twin and AI platforms with robust cybersecurity measures, access controls, and compliance with industry standards.

By anticipating these challenges and addressing them proactively, plant managers can smoothly implement Digital Twin + AI, achieving operational excellence without unnecessary headaches. Remember, the technology is powerful but success depends on strategy, planning, and execution.

Future Trends in Digital Twin and AI for Plants

We’re in 2025, and the industrial landscape is evolving faster than ever. Digital Twin and AI technologies aren’t just a fad they’re shaping the next decade of plant operations. Understanding these trends can help you stay ahead of the curve and leverage opportunities before competitors catch up.

- Edge AI and Real-Time Analytics

While traditional AI relies on centralized servers, Edge AI brings intelligence directly to the plant floor. By processing data locally on machines and sensors, decisions happen in milliseconds, enabling instant adjustments to process parameters and improving safety and efficiency. Imagine turbines or pumps that can self-optimize in real time no waiting for cloud processing. - Hybrid Twins: Combining Physics and Data Models

Next-generation Digital Twins are evolving into hybrid models that integrate physics-based simulations with AI-driven predictions. This combination provides more accurate insights, especially in complex processes where historical data alone isn’t enough. For example, predicting how a chemical reactor reacts to new feedstock blends becomes faster and more precise. - Predictive and Prescriptive Capabilities

AI won’t just predict failures anymore it will recommend optimal actions. Plants will move from predictive maintenance to prescriptive maintenance, where the system not only warns you about a potential problem but also suggests the exact steps to fix it, including spare parts, scheduling, and resource allocation. - Sustainability-Driven Operations

Digital Twin + AI synergy will increasingly focus on sustainability. AI will optimize energy consumption, reduce emissions, and help plants comply with increasingly stringent environmental regulations all while maintaining production efficiency. Think of it as doing more with less, which is critical in today’s competitive industrial world. - Enhanced Human-Machine Collaboration

Operators will work hand-in-hand with AI-powered Digital Twins, shifting from manual monitoring to decision facilitation. This trend will improve safety, speed up troubleshooting, and allow human expertise to focus on high-value strategic decisions rather than repetitive operational tasks. - Continuous Learning Systems

Future Digital Twins will become self-improving systems. AI algorithms will continuously learn from historical and real-time data, refining predictions, improving accuracy, and generating new insights over time. This means your plant’s operational intelligence keeps getting smarter, creating a long-term competitive advantage.

In short, the future is about real-time, intelligent, sustainable, and self-improving plant operations. Companies that embrace these trends early will not just survive they’ll lead the next era of industrial excellence.

Measuring ROI and Success Metrics

Investing in Digital Twin and AI synergy is a big decision, so it’s natural for plant managers to ask: “How do I know it’s worth it?” Measuring ROI isn’t just about cost savings it’s about improved efficiency, safety, and long-term competitiveness.

Reduction in Unplanned Downtime

One of the clearest metrics is the decrease in unplanned equipment downtime. AI-driven predictive maintenance, powered by Digital Twins, allows teams to anticipate failures before they occur. For example, a refinery might see unplanned downtime drop by 25–30% within the first year, translating to millions in cost savings.

Maintenance Cost Savings

Traditional maintenance schedules often lead to over-maintenance or unnecessary replacements. Predictive maintenance ensures resources are used only when necessary. By tracking reductions in labor hours, parts usage, and emergency repairs, plants can quantify direct cost savings.

Energy Efficiency Gains

Energy optimization is a major ROI factor. By leveraging AI to analyze Digital Twin data, plants can reduce fuel, electricity, and water usage. Many industrial operations report 5–10% reductions in energy costs, which adds up quickly given the scale of modern facilities.

Safety and Compliance Metrics

While harder to quantify in dollars, improved safety and regulatory compliance has immense value. Fewer incidents mean lower insurance premiums, reduced fines, and improved workforce morale. AI-powered Digital Twins can track near-misses and predicted hazards, helping organizations document compliance and risk mitigation effectively.

Operational Performance Indicators

AI + Digital Twin synergy enables tracking of key performance indicators (KPIs) such as production throughput, yield optimization, and process efficiency. Monitoring these metrics shows how well operations are optimized and highlights areas for continuous improvement.

Employee Productivity and Decision Quality

Operators spend less time firefighting and more time on strategic decisions. Tracking changes in productivity and decision-making speed can reveal intangible ROI, which is often just as impactful as cost savings.

Long-Term Asset Life Extension

By accurately predicting wear and maintenance needs, equipment life can be extended. This reduces capital expenditure and enhances overall ROI.

In essence, ROI from Digital Twin + AI synergy isn’t just theoretical it’s tangible, measurable, and multifaceted. By tracking downtime reduction, cost savings, energy efficiency, safety, and operational performance, plant managers can confidently justify their investment and continually improve their operations.

Preparing Your Plant for Digital Twin + AI

Before jumping headfirst into implementing Digital Twin and AI synergy, preparation is key. The most successful plants don’t just install technology—they create the foundation for long-term success. Here’s how to get your plant ready in 2025.

Assess Current Infrastructure

Start by evaluating your existing systems: SCADA, ERP, CMMS, sensors, and IoT devices. Identify which assets are already digitally instrumented and which may require upgrades. Without reliable data streams, your Digital Twin and AI won’t deliver accurate predictions or actionable insights.

Define Clear Objectives

Know what you want to achieve. Are you focused on reducing downtime, optimizing energy use, improving safety, or all of the above? Defining measurable objectives will help you prioritize assets, allocate resources, and track ROI effectively.

Build a Cross-Functional Team

Digital Twin + AI implementation requires collaboration across operations, maintenance, IT, and management. Establish clear roles and responsibilities to ensure smooth communication and alignment on goals. The synergy works best when teams work together rather than in silos.

Invest in Training

Operators and engineers must understand how to interact with the Digital Twin, interpret AI insights, and act on recommendations. Hands-on training, simulations, and scenario-based exercises will ensure your team can confidently leverage the technology.

Start with Pilot Projects

Instead of attempting a full-scale rollout, begin with one critical process or asset. Monitor results, fine-tune AI algorithms, and validate predictions. Pilot successes build confidence and provide a blueprint for scaling across the plant.

Ensure Data Governance and Quality

Accurate, high-quality data is the lifeblood of Digital Twin + AI systems. Implement data validation, calibration, and governance protocols to maintain reliability. Consistent, clean data ensures predictions are trustworthy and actionable.

Plan for Continuous Improvement

Digital Twin and AI aren’t “set and forget.” The system should evolve alongside your plant, learning from new data and adjusting predictions. Establish feedback loops to refine algorithms, improve simulations, and maximize operational benefits over time.

By following these steps, plant managers can lay the groundwork for a successful Digital Twin + AI implementation, ensuring that technology delivers measurable improvements in efficiency, safety, and profitability. The preparation phase may take time, but it sets the stage for long-term success and competitive advantage.

Conclusion

By now, it should be clear: Digital Twin and AI synergy isn’t just a buzzword it’s a transformative approach that’s reshaping how industrial plants operate in 2025. From predictive maintenance and energy optimization to enhanced safety and smarter operational decisions, the benefits are tangible, measurable, and game-changing.

Plants leveraging this synergy are seeing fewer unplanned shutdowns, optimized energy use, and longer equipment life, while simultaneously improving workforce safety and regulatory compliance. Case studies from oil & gas refineries, chemical plants, and power generation facilities confirm one key takeaway: investing in Digital Twin + AI isn’t optional it’s essential for staying competitive.

But here’s the catch: technology alone isn’t enough. Success depends on preparation, strategy, and execution. Plant managers must assess infrastructure, prioritize assets, ensure data quality, build cross-functional teams, and implement pilot projects before scaling. Training and continuous improvement are equally crucial without them, even the most advanced AI or Digital Twin will fall short of its potential.

The opportunities are massive. Imagine a plant where AI predicts equipment failure before it happens, Digital Twins simulate optimal process conditions in real-time, and energy usage is continuously minimized while safety risks are proactively managed. This isn’t a futuristic dream it’s what leading plants are doing right now.

Start small, think strategically, and act decisively. Identify a critical asset, implement a Digital Twin, integrate AI insights, and track your ROI. Share your wins across the organization and scale gradually. The sooner you embrace this synergy, the faster your plant will reap the rewards lower costs, higher efficiency, improved safety, and long-term competitiveness.

Don’t wait for competitors to pull ahead. Digital Twin and AI synergy is the future of industrial plant operations, and the future is now. Your move: take the first step today, and transform your operations into a predictive, proactive, and intelligent ecosystem.