- Introduction

- Understanding AI-Powered Predictive Maintenance in Power Plants

- Real-World Success Stories of AI-Powered Predictive Maintenance in Power Plants

- Step-by-Step Guide to Implement AI Predictive Maintenance in Power Plants

- Key Benefits of AI Predictive Maintenance for Power Plants

- Common Challenges & How to Overcome Them

- Step-by-Step Implementation Roadmap

- Real-World Case Study: AI Predictive Maintenance in Action

- Common Pitfalls and How to Avoid Them

- Future Trends in AI Predictive Maintenance for Power Plants

- Conclusion

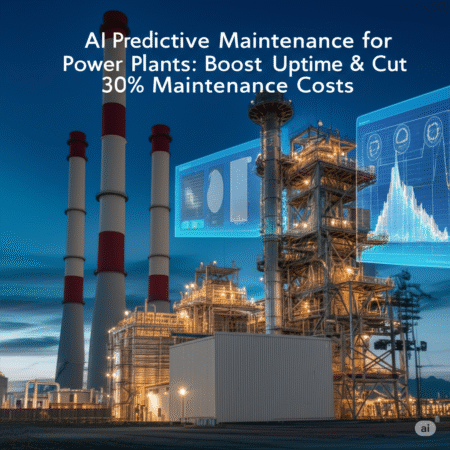

Introduction

In the power generation industry, unplanned downtime is more than just an inconvenience it’s a million-dollar problem.

Every minute a gas turbine is offline, every hour a boiler is out of service, the plant is bleeding revenue, risking safety, and missing production targets.

Traditional maintenance strategies, like scheduled preventive maintenance, can reduce some risks, but they also come with inefficiencies: replacing parts too early, missing hidden failures, or relying on guesswork instead of hard data.

That’s where AI-driven predictive maintenance comes in.

By leveraging machine learning, IoT sensors, and real-time analytics, power plants can detect micro-anomalies-signs of wear, vibration changes, temperature spikes-weeks before a failure occurs.

According to a McKinsey study, companies implementing AI-based predictive maintenance have reduced downtime by up to 50% and maintenance costs by 10 – 40%.

For power plants, where critical assets like turbines, generators, transformers, and boilers operate under extreme conditions, AI isn’t just an upgrade it’s a necessity for staying competitive in a tightening energy market.

In this article, we’ll explore how AI transforms predictive maintenance for power plants, from the technologies that make it possible to real-world success stories, and provide a clear roadmap you can follow to start your own AI PdM journey.

Understanding AI-Powered Predictive Maintenance in Power Plants

Why It Matters

In the high-stakes world of power generation, every minute of downtime translates into significant financial loss and potential service disruptions. Predictive maintenance powered by Artificial Intelligence (AI) is not just another buzzword-it’s a game-changer for utilities and independent power producers. By integrating machine learning algorithms, real-time sensor data, and historical performance records, AI enables plant operators to predict equipment failures before they happen, schedule maintenance more efficiently, and optimize asset utilization.

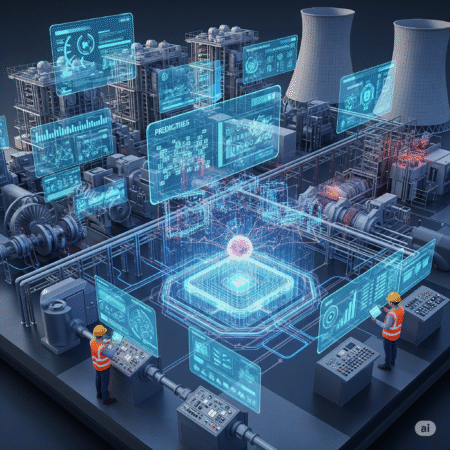

How It Works – The AI Predictive Maintenance Workflow

To appreciate its impact, you need to understand the process:

- Data Collection from Sensors and SCADA Systems

Power plants are already equipped with thousands of sensors monitoring everything from turbine vibration levels to boiler temperature and pressure. AI taps into this data stream via SCADA or Distributed Control Systems (DCS). - Data Preprocessing & Cleansing

Raw sensor data can be messy—noise, missing values, or inconsistent readings. AI platforms filter and normalize the data to ensure accuracy before analysis. - Machine Learning Model Training

Using historical operational data and past failure events, AI trains predictive models to identify patterns that precede equipment issues-such as specific vibration signatures, pressure spikes, or abnormal heat patterns. - Real-Time Anomaly Detection

Once deployed, the AI model continuously monitors live data. The moment it detects anomalies that match failure patterns, it raises alerts well before the actual breakdown. - Maintenance Scheduling Optimization

Instead of following rigid, calendar-based schedules, maintenance teams get prioritized, data-driven work orders-reducing unnecessary interventions and focusing resources where they’re needed most.

Key AI Technologies Driving Predictive Maintenance

- Machine Learning (ML) – Algorithms that adapt and improve accuracy over time as more data is fed.

- Deep Learning – Neural networks that detect complex, non-linear failure patterns.

- Natural Language Processing (NLP) – Helps in processing maintenance logs and unstructured technical reports.

- Edge AI – Runs analytics directly on-site for ultra-low latency decision-making.

The Benefits Over Traditional Maintenance

| Traditional Maintenance | AI-Powered Predictive Maintenance |

|---|---|

| Reactive (repair after failure) | Proactive (fix before failure) |

| Scheduled at fixed intervals | Scheduled only when data shows a real need |

| High downtime risk | Minimal downtime |

| Generic spare parts inventory | Optimized inventory based on predicted needs |

Pro Tip:

Companies implementing AI-driven predictive maintenance in their power plants often see:

- 20 – 50% reduction in unplanned outages

- 10 – 40% decrease in maintenance costs

- 3 – 5% increase in asset availability

Real-World Success Stories of AI-Powered Predictive Maintenance in Power Plants

Why Case Studies Matter

It’s one thing to talk about AI in theory it’s another to see it saving millions in real operations. The following real-world examples show how AI-powered predictive maintenance is already transforming power plants across the globe.

Duke Energy (United States) – Preventing Turbine Failures Before They Happen

Challenge:

Duke Energy, one of the largest electric power holding companies in the US, struggled with unexpected turbine shutdowns that caused costly outages and regulatory headaches.

Solution:

They implemented an AI-driven analytics platform that monitored 500+ operational parameters per turbine in real time.

Impact:

- Detected early-stage bearing wear two months before failure

- Reduced unplanned turbine downtime by 45%

- Saved $4 million annually in maintenance and outage costs

RWE (Germany/UK) – Extending the Life of Aging Assets

Challenge:

With many assets approaching the end of their lifecycle, RWE needed to maintain reliability while minimizing capital expenditures.

Solution:

AI predictive models analyzed vibration, temperature, and output efficiency data from older coal and gas plants, flagging components at risk before breakdown.

Impact:

- Extended equipment life by up to 7 years

- Lowered annual maintenance costs by 30%

- Reduced emergency maintenance events by over 50%

EDF Energy (UK) – Boosting Reliability in Nuclear Plants

Challenge:

For nuclear facilities, unplanned outages aren’t just expensive they can trigger compliance issues and safety concerns.

Solution:

EDF deployed AI-powered anomaly detection across its UK nuclear fleet, integrating real-time SCADA data with historical maintenance logs.

Impact:

- Achieved 99% plant availability in peak demand months

- Reduced the need for manual inspections by 40%

- Improved safety by detecting abnormal coolant flow patterns early

NextEra Energy (US) – Renewable Energy Asset Optimization

Challenge:

Wind turbines and solar farms face unique wear-and-tear patterns that differ from traditional fossil fuel plants.

Solution:

NextEra integrated AI predictive maintenance to monitor turbine blade integrity and solar panel degradation using drone imagery and IoT sensors.

Impact:

- Increased wind farm output by 6% annually

- Reduced maintenance truck rolls by 35%

- Achieved faster fault detection, cutting downtime from days to hours

The Takeaway:

Across continents, AI-powered predictive maintenance isn’t just theory-it’s delivering measurable ROI, extending asset lifespans, and ensuring uninterrupted power supply. These results aren’t outliers-they’re the new industry standard.

Step-by-Step Guide to Implement AI Predictive Maintenance in Power Plants

You don’t have to be a tech giant to get started with AI predictive maintenance.

Here’s a proven roadmap that leading power companies use to roll out AI-driven maintenance whether you’re running a coal, gas, nuclear, or renewable plant.

Step 1: Define Your Maintenance Objectives

Before touching any technology, clarify your goals:

- Reduce unplanned outages by X%

- Extend asset life by Y years

- Cut O&M (Operations & Maintenance) costs by $Z annually

Pro tip: Tie these goals directly to business KPIs so you can prove ROI later.

Step 2: Conduct an Asset Health Audit

- Inventory all critical equipment (turbines, boilers, generators, transformers, etc.)

- Review historical failure records and downtime causes

- Prioritize assets with the highest impact on operations

Why it matters: AI works best when it starts with high-value, high-risk assets.

Step 3: Deploy IoT Sensors and Data Infrastructure

You can’t predict what you don’t measure. Install:

- Vibration sensors for rotating machinery

- Temperature and pressure transducers

- Current and voltage monitors

- Integrate with your SCADA/DCS systems

Ensure you have secure cloud or on-premise storage to handle large datasets.

Step 4: Choose the Right AI Platform

Look for:

- Compatibility with your existing systems (no rip-and-replace)

- Real-time anomaly detection

- Predictive modeling with historical data integration

- User-friendly dashboards for O&M teams

Examples include GE Predix, Siemens MindSphere, SparkCognition, or open-source frameworks if you want full control.

Step 5: Build and Train Your AI Models

- Feed your system with historical maintenance logs, sensor data, and failure records

- Include operating conditions (load, ambient temperature, fuel type, etc.)

- Train models to detect early signs of degradation specific to your plant’s environment

Step 6: Integrate with Your Maintenance Workflow

The AI’s output should trigger:

- Automatic work orders in your CMMS (Computerized Maintenance Management System)

- Alerts for inspection before a failure occurs

- Adjustments to preventive maintenance schedules

Goal: Move from calendar-based to condition-based maintenance.

Step 7: Monitor, Optimize, and Scale

- Track KPIs: downtime reduction, cost savings, reliability index

- Continuously retrain AI models with new data

- Scale from one pilot plant to your entire fleet once ROI is proven

Quick Win Tip: Start small. Pick one high-impact asset, run a 6-month pilot, prove savings, then expand. This “land and expand” approach keeps risk low while securing management buy-in.

Key Benefits of AI Predictive Maintenance for Power Plants

AI predictive maintenance is not just about preventing breakdowns it’s about transforming maintenance from a cost center into a profit driver.

Here’s what leading power producers are experiencing after adoption:

Read More: AI-Powered Predictive Maintenance in Oil & Gas Complete Guide (2025-2030)

Dramatic Reduction in Unplanned Downtime

- Typical savings: 30 – 50% fewer unexpected outages

- Example: A 500 MW combined cycle plant avoiding a single 24-hour outage can save $250,000 – $500,000 in lost generation revenue.

- AI catches failure signatures weeks in advance, giving teams the time to act.

Lower Operations & Maintenance (O&M) Costs

- AI enables condition-based maintenance, so parts are replaced only when needed—not on arbitrary schedules.

- Plants report 10–40% reduction in maintenance costs by eliminating unnecessary preventive work.

- Example: Reducing annual maintenance budget from $5M to $3.5M = $1.5M/year savings.

Extended Asset Life

- Optimized operating conditions reduce wear-and-tear on expensive assets.

- Extending turbine overhaul intervals from 3 years to 4 years can save $1–2M per unit.

- Transformers, boilers, and generators last longer when stress is monitored in real time.

Improved Safety and Compliance

- AI detects abnormal operating conditions before they cause hazardous events.

- Reduces incidents that could trigger regulatory fines or shutdowns.

- Example: Predicting insulation failure in a high-voltage transformer avoids fire hazards and downtime.

Faster Decision-Making with Real-Time Insights

- AI dashboards give plant managers live health scores for each asset.

- Engineers can prioritize maintenance work orders based on risk and impact.

- This shifts the maintenance team’s role from reactive fire-fighting to strategic asset management.

ROI That Pays Back in Months

- Many plants achieve full ROI in 6 – 12 months after deployment.

- Long-term benefits compound: reduced downtime, lower maintenance spend, higher generation output.

- For a fleet of plants, savings easily run into tens of millions of dollars annually.

Bottom line: AI predictive maintenance doesn’t just keep the lights on – it keeps profit margins healthy, safety records clean, and competitive advantage strong.

Common Challenges & How to Overcome Them

Adopting AI predictive maintenance in power plants sounds like a silver bullet – but without the right approach, it can hit roadblocks.

Here are the most common challenges and practical strategies to overcome them.

Data Quality Issues

The problem:

- Many plants have incomplete, inconsistent, or siloed historical maintenance data.

- IoT sensor readings may have gaps, noise, or calibration errors.

How to fix it:

- Start with data cleansing and validation before AI training.

- Implement automated anomaly filtering to remove false readings.

- Use edge analytics to preprocess data at the source.

Legacy Equipment Integration

The problem:

- Older turbines, boilers, or control systems may not have modern sensors or connectivity.

- Data extraction can be costly or technically challenging.

How to fix it:

- Retrofit low-cost wireless sensors for vibration, temperature, and pressure.

- Use protocol converters to integrate Modbus, OPC, and legacy SCADA systems with AI platforms.

- Prioritize high-value assets first to show ROI early.

Resistance to Change from Maintenance Teams

The problem:

- Technicians may distrust AI recommendations, preferring manual inspections.

- Perception that AI will replace jobs rather than support them.

How to fix it:

- Train staff early and show how AI complements human expertise.

- Share success stories from similar plants to build confidence.

- Make AI outputs transparent – show why a prediction is made, not just the result.

Cybersecurity Risks

The problem:

- AI predictive maintenance platforms rely on constant data streaming from OT (Operational Technology) systems, which could become a cyber attack vector.

How to fix it:

- Implement secure data encryption for both in-transit and at-rest data.

- Use segmented networks to isolate AI systems from critical control loops.

- Regularly update firmware and security patches.

High Initial Investment

The problem:

- AI projects require upfront spending for sensors, data infrastructure, and software licenses.

- Management may hesitate without a clear payback model.

How to fix it:

- Start with a pilot project on 2 – 3 critical assets to demonstrate ROI quickly.

- Use a subscription-based AI service to spread costs over time.

- Present a clear financial case showing downtime cost avoidance and maintenance savings.

Pro Tip: Plants that succeed treat AI predictive maintenance as a long-term operational strategy, not a one-off tech experiment.

They invest in continuous model retraining so the AI adapts as equipment ages and operating patterns change.

Step-by-Step Implementation Roadmap

Implementing AI predictive maintenance in a power plant isn’t just about buying software-it’s a structured process.

Here’s a proven 7-step roadmap to ensure a smooth and successful rollout.

Step 1 – Define Objectives and Scope

- Ask the right questions: What problem are we solving – reducing unplanned downtime, optimizing spare parts, or extending asset life?

- Pick target assets: Focus first on high-value, high-risk equipment like turbines, generators, boilers, or critical pumps.

- Set measurable KPIs: e.g., 20% reduction in unplanned outages within 12 months.

Step 2 – Assess Current Infrastructure

- Evaluate your existing sensors, SCADA, and DCS systems.

- Identify data availability gaps and plan sensor retrofits if needed.

- Check network capacity and storage for handling continuous IoT data streams.

Step 3 – Data Collection and Preparation

- Gather historical maintenance logs, sensor data, and operational records.

- Clean the data – remove duplicates, fill missing values, and align time stamps.

- Apply feature engineering to make the dataset AI-ready.

Step 4 – Choose the Right AI Platform

- Look for a platform that supports real-time analytics, edge computing, and integration with your OT systems.

- Evaluate cloud vs. on-premises deployment based on security, latency, and cost.

- Ensure the vendor has industry-specific AI models for power generation equipment.

Step 5 – Pilot Implementation

- Start small – monitor 2–3 critical assets.

- Configure predictive models, set thresholds for alerts, and test on live data.

- Validate AI predictions against manual inspections to fine-tune accuracy.

Step 6 – Train & Engage the Maintenance Team

- Conduct hands-on training sessions for engineers and technicians.

- Explain how AI generates predictions – use transparent dashboards and visual alerts.

- Encourage feedback loops so the AI model improves continuously.

Step 7 – Scale and Optimize

- Once the pilot proves ROI, expand to more assets and plants.

- Automate work order creation in your CMMS when AI detects early faults.

- Keep models updated with continuous retraining as equipment ages and conditions change.

Pro Tip:

Don’t treat the AI system as “set it and forget it.” The best results come from human + AI collaboration, where technicians use AI insights as an early-warning radar, not a replacement for their expertise.

Real-World Case Study: AI Predictive Maintenance in Action

To move from theory to practice, let’s look at how one major power plant implemented AI predictive maintenance—and the results they achieved.

Background

- Plant type: 1,000 MW combined-cycle gas turbine (CCGT) power plant

- Location: Southeast Asia

- Challenge:

- Frequent forced outages on one of the main gas turbines.

- Average downtime: 5 days per incident.

- Annual loss: ~$2.5 million due to lost generation and repair costs.

Solution

- Critical Asset Selection

The maintenance team focused on the main gas turbine and heat recovery steam generator (HRSG), as these accounted for 70% of downtime events. - Sensor Upgrade & Data Integration

- Installed high-frequency vibration sensors and oil quality sensors.

- Integrated readings with the existing SCADA system.

- Historical data from the last 3 years was cleaned and fed into the AI model.

- AI Platform Deployment

- Chose an edge AI system for low-latency fault detection.

- Models were trained to detect patterns linked to bearing wear and blade fatigue.

- Predictive Alerts & Workflow Integration

- Alerts were sent directly to the CMMS, triggering automated work orders.

- Maintenance crew received mobile notifications with fault probability scores.

Results After 12 Months

| Metric | Before AI | After AI | Improvement |

|---|---|---|---|

| Forced Outages | 8/year | 2/year | -75% |

| Average Downtime per Incident | 5 days | 1 day | -80% |

| Annual Maintenance Cost | $4.0M | $2.5M | -37.5% |

| ROI on AI Investment | – | Payback in 9 months | ✅ |

Key Takeaways

- Small, targeted pilots work best – start with the assets that cause the most downtime.

- Sensor data quality matters – garbage in, garbage out.

- Technician buy-in is crucial – AI only works if the team trusts and uses it.

Bottom line: This case shows that AI predictive maintenance isn’t just a fancy concept – it can save millions in avoided downtime, extend equipment life, and give power plants a competitive edge.

Common Pitfalls and How to Avoid Them

Even with strong business cases, many AI predictive maintenance projects in power plants stall or fail. The good news? Most of these failures are avoidable.

Poor Data Quality

The pitfall: AI models can’t make accurate predictions with incomplete, noisy, or inconsistent sensor data.

Avoid it by:

- Establishing strict data validation rules.

- Performing regular sensor calibration.

- Cleaning historical data before feeding it into the model.

Lack of Cross-Functional Collaboration

The pitfall: Engineering, IT, and operations teams often work in silos, causing delays and integration issues.

Avoid it by:

- Forming a cross-functional implementation team from day one.

- Holding regular alignment meetings between operations, maintenance, and IT staff.

Overestimating AI’s Capabilities

The pitfall: Believing AI will solve all problems instantly. Predictive maintenance is a tool, not a magic wand.

Avoid it by:

- Setting realistic KPIs.

- Starting with a pilot project before scaling.

- Combining AI predictions with human expertise.

Ignoring Change Management

The pitfall: Technicians may resist using AI tools if they feel it threatens their jobs or expertise.

Avoid it by:

- Involving technicians early in the process.

- Providing training to build confidence in AI-assisted decisions.

- Showing how AI helps them work smarter, not harder.

Insufficient ROI Tracking

The pitfall: Without tracking savings and benefits, management may lose interest or cut funding.

Avoid it by:

- Establishing baseline performance metrics before implementation.

- Tracking avoided downtime, cost savings, and ROI monthly.

- Reporting results in clear, non-technical terms for stakeholders.

Pro tip: Treat AI predictive maintenance as a continuous improvement journey, not a one-off project. The more data your model processes, the more accurate – and valuable – it becomes.

Future Trends in AI Predictive Maintenance for Power Plants

The predictive maintenance landscape is evolving rapidly, and power plants that want to stay competitive must anticipate what’s next. Here are the trends shaping the future:

Edge AI for Real-Time Decision-Making

Instead of sending all data to the cloud, edge AI processes data directly at or near the equipment.

- Why it matters: Enables instant anomaly detection without latency.

- Impact on power plants: Immediate shutdown triggers, faster fault isolation, and reduced risk of cascading failures.

Digital Twins Integration

A digital twin is a dynamic, virtual replica of physical assets.

- Why it matters: Allows real-time simulation of “what-if” scenarios before taking action.

- Impact on power plants: Operators can test maintenance strategies virtually, reducing trial-and-error costs.

AI-Driven Autonomous Maintenance

Future AI systems won’t just predict failures-they’ll schedule and execute maintenance autonomously.

- Why it matters: Reduces reliance on human scheduling and minimizes downtime.

- Impact on power plants: Streamlined work orders, automated spare parts procurement, and coordinated crew assignments.

Predictive Maintenance as a Service (PdMaaS)

Instead of building in-house AI systems, power plants will subscribe to cloud-based PdM solutions.

- Why it matters: Lower upfront investment and faster deployment.

- Impact on power plants: Access to advanced AI without hiring large data science teams.

Sustainability-Driven AI Models

Regulatory pressure and ESG (Environmental, Social, and Governance) goals are pushing plants to integrate energy efficiency into predictive maintenance.

- Why it matters: Maintenance schedules can now prioritize not just uptime, but also carbon footprint reduction.

- Impact on power plants: AI that balances operational performance with emissions targets.

Self-Learning AI Models

Current models often require retraining with new data. The future lies in self-learning AI that adapts continuously.

- Why it matters: Faster adaptation to changing load profiles and fuel types.

- Impact on power plants: Predictive accuracy remains high even under new operating conditions.

Bottom line: The next generation of AI predictive maintenance will be faster, more autonomous, and sustainability-focused. Power plants that start adapting now will not only reduce downtime but also position themselves as leaders in operational excellence.

Conclusion

AI-powered predictive maintenance is no longer a futuristic concept – it’s a present-day competitive advantage for power plants. By leveraging real-time data, advanced machine learning algorithms, and intelligent automation, operators can predict failures before they happen, cut unplanned downtime, and extend equipment lifespan.

The key takeaway?

This isn’t just about fixing machines faster – it’s about transforming maintenance into a strategic, profit-driving function. Those who adopt AI early will enjoy lower operational costs, higher reliability, and stronger compliance with evolving energy regulations.

If you’re in the power generation industry, now is the time to act:

- Evaluate your current maintenance strategy – is it reactive, preventive, or predictive?

- Start with a pilot project using AI on critical assets.

- Partner with technology providers who specialize in energy sector predictive analytics.

Don’t wait for a breakdown to prove the value of predictive maintenance – let AI prove it every single day.

👉 Begin your journey toward smarter, more resilient power plant operations today.