- Introduction: Why Power Plants Can’t Afford Downtime

- Traditional vs AI Predictive Maintenance

- Key AI Technologies Transforming Power Plant Maintenance

- Core Benefits of AI-Driven Predictive Maintenance in Power Plants

- Step-by-Step Implementation Framework for Power Plants

- Step 1. Define Objectives and KPIs

- Step 2. Conduct Asset Criticality Assessment

- Step 3. Install or Upgrade Sensor Infrastructure

- Step 4. Integrate Data Sources

- Step 5. Select the Right AI Predictive Maintenance Platform

- Step 6. Train AI Models on Historical Data

- Step 7. Set Up Alerting and Decision Protocols

- Step 8. Continuous Improvement and Feedback Loop

- Technical Requirements for AI Predictive Maintenance in Power Plants

- Data Strategy: From Collection to AI Insights

- Implementation Roadmap for AI Predictive Maintenance in Power Plants

- Case Studies: AI Predictive Maintenance Success in Power Plants

- Future Outlook & Emerging Trends in AI Predictive Maintenance for Power Plants

- Key Takeaways for Power Plant Operators

Introduction: Why Power Plants Can’t Afford Downtime

In the world of power generation, downtime is measured in dollars millions of them.

When a power plant goes offline unexpectedly, it’s not just an inconvenience it’s a financial and operational crisis. A single hour of unplanned downtime in a large combined-cycle plant can cost between $100,000 and $300,000 in lost generation revenue, contractual penalties, and emergency repair expenses. For coal and nuclear facilities, the numbers climb even higher.

But the impact doesn’t stop there.

Every minute without generation capacity puts grid stability at risk, forces utilities to buy expensive replacement power from other sources, and can trigger cascading effects across industries that depend on stable energy. And in an era where renewable integration and electrification are accelerating, the tolerance for outages is shrinking fast.

Here’s the truth:

Traditional preventive maintenance schedules based on fixed intervals or operating hours are no longer enough. They often result in two costly scenarios:

Over-maintenance – Parts replaced too early, wasting budget.

Under-maintenance – Problems missed until they cause catastrophic failures.

That’s where AI-powered predictive maintenance steps in. By analyzing vast streams of operational data from SCADA systems, sensors, vibration monitors, thermal cameras, and digital twins, AI models can detect early signs of equipment degradation weeks or even months before human operators can spot them.

The payoff is massive:

Up to 30% reduction in operations & maintenance (O&M) costs.

20%+ increase in equipment uptime and availability.

Extended asset lifespan by years, not months.

In short, AI predictive maintenance is not just a “nice-to-have” for modern power plants-it’s fast becoming a strategic necessity for utilities that want to remain competitive, compliant, and resilient in the face of rising energy demands.

Traditional vs AI Predictive Maintenance

For decades, power plants relied on preventive maintenance (PM) schedules set by OEM recommendations, regulatory requirements, or industry best practices. While this approach reduced some risk compared to purely reactive repairs, it came with serious inefficiencies.

Traditional Preventive Maintenance

In the traditional model:

Maintenance is performed at fixed intervals – e.g., every 3 months, 6 months, or after a set number of operating hours.

Inspections and servicing are calendar-driven, not condition-driven.

Failures that occur between scheduled inspections often go undetected until they cause downtime.

The problems with this model:

Over-maintenance – Components get replaced while still in good condition, leading to wasted parts, labor, and budget.

Under-maintenance – Critical issues arise unexpectedly between scheduled maintenance, leading to unplanned shutdowns.

Limited insight – Maintenance decisions are based on historical assumptions, not real-time equipment health data.

Reactive bias – Plants still spend a significant portion of time firefighting unexpected breakdowns.

In numbers:

Studies by the Electric Power Research Institute (EPRI) show that traditional preventive maintenance can waste 30–40% of the maintenance budget without significantly reducing risk of failure.

AI-Powered Predictive Maintenance

AI flips the script. Instead of relying on the calendar, it relies on live operational data from sensors, IoT devices, and control systems.

How it works:

Continuous Data Collection – Sensors capture vibration, temperature, acoustic signals, thermal imaging, lubricant analysis, and electrical readings 24/7.

AI Pattern Recognition – Machine learning algorithms detect subtle deviations from normal operating conditions.

Failure Prediction – AI models predict the probability of component failure weeks or months in advance.

Targeted Intervention – Maintenance teams focus on assets that actually need attention, at the right time.

The benefits:

Cost efficiency – Maintenance spend can drop by 20–30% due to better targeting.

Less downtime – Early intervention prevents catastrophic failures.

Longer asset life – Machines are serviced based on real needs, reducing wear from unnecessary intervention.

Higher safety and compliance – Potential hazards are detected before they escalate.

Real-World Example

In 2023, a major gas-fired power plant in Texas deployed AI-driven predictive maintenance across its turbines and feedwater pumps. Within 8 months:

Unplanned outages dropped by 45%.

Annual O&M savings exceeded $2.1 million.

Turbine blade replacement intervals extended by 14 months without compromising safety.

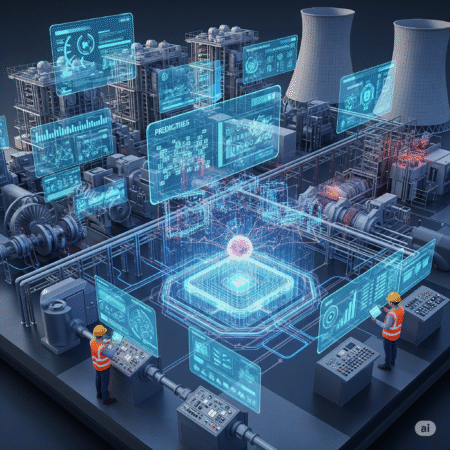

Key AI Technologies Transforming Power Plant Maintenance

AI-powered predictive maintenance isn’t just “one technology” – it’s a combination of advanced analytics, IoT connectivity, and intelligent algorithms working together to provide a real-time view of asset health.

Here’s the breakdown of the key technologies driving this transformation:

Machine Learning (ML) for Pattern Recognition

Function: ML algorithms analyze historical and real-time equipment data to identify patterns linked to normal and abnormal operations.

Example: If a turbine bearing typically operates at a vibration level of 3 mm/s, but readings creep toward 4 mm/s in a specific frequency range, ML flags it as a potential early-stage bearing defect.

Impact:

Detects failure modes invisible to human operators.

Learns and adapts over time as more data is collected.

Reduces false alarms by distinguishing between normal operational fluctuations and real failure signals.

Digital Twin Technology

Function: Creates a virtual replica of critical power plant assets – turbines, boilers, pumps – updated in real time with live sensor data.

Use Case: Operators can simulate “what-if” scenarios, such as running a turbine at a higher load, to see how it impacts wear and performance before doing it physically.

Impact:

Enables proactive decision-making.

Predicts remaining useful life (RUL) for each asset.

Improves planning for outages and component replacements.

IoT Sensors & Edge Computing

Function: IoT sensors measure vibration, temperature, pressure, acoustic emissions, lubricant quality, and more.

Edge computing processes the data on-site before sending it to cloud AI systems, reducing latency.Example: In rotating machinery, vibration sensors detect misalignment, imbalance, or lubrication issues long before a catastrophic breakdown.

Impact:

Real-time monitoring without overwhelming central systems.

Faster response to developing issues.

Lower bandwidth costs compared to cloud-only solutions.

Natural Language Processing (NLP) for Maintenance Logs

Function: AI reads and interprets decades of maintenance reports, technician notes, and OEM manuals.

Example: NLP models can identify recurring fault patterns (e.g., “seal leak” in pump #4 every summer) and suggest preventive action.

Impact:

Turns unstructured human-written reports into actionable insights.

Preserves institutional knowledge when senior engineers retire.

Computer Vision for Visual Inspections

Function: AI-powered cameras and drones visually inspect plant infrastructure – from boiler tubes to transmission lines.

Example: A drone with thermal imaging detects hotspots in electrical insulators, preventing arc faults.

Impact:

Reduces the need for risky manual inspections in hazardous zones.

Enables faster coverage of large facilities.

Finds defects invisible to the naked eye.

Predictive Analytics Dashboards

Function: Centralized dashboards display health scores, RUL predictions, and maintenance recommendations in real time.

Impact:

Improves coordination between operations and maintenance teams.

Supports better budgeting for spare parts and manpower.

Enhances decision-making for load management and dispatch.

Key Takeaway:

It’s not just AI in isolation – the real power comes from combining ML + IoT + Digital Twins + Edge Computing + Computer Vision + Predictive Analytics into a unified maintenance ecosystem.

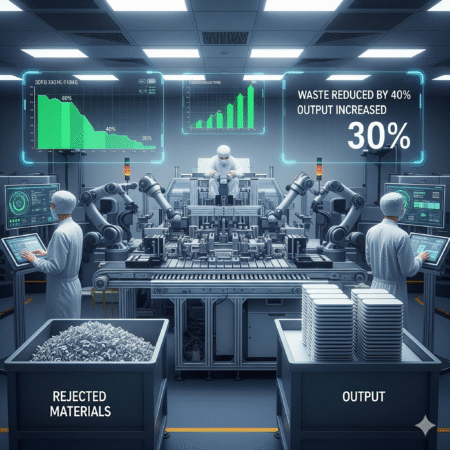

Core Benefits of AI-Driven Predictive Maintenance in Power Plants

AI-driven predictive maintenance isn’t just a buzzword – it delivers measurable operational, financial, and safety improvements.

Here’s the breakdown of the most impactful benefits:

Reduced Unplanned Downtime

Why it matters: Every hour of downtime in a large power plant can cost $50,000–$150,000 in lost generation revenue.

AI advantage:

Detects failures weeks or even months before they happen.

Allows repairs to be scheduled during planned outages instead of emergency shutdowns.

Real-world example: A gas turbine operator used AI-based vibration analytics to catch a bearing fault three weeks early, preventing a $2.5M loss.

Lower Maintenance Costs

Why it matters: Traditional time-based maintenance often results in unnecessary part replacements and excessive labor costs.

AI advantage:

Moves from calendar-based to condition-based maintenance.

Extends asset life by replacing parts only when needed.

Impact: Power plants adopting AI predictive maintenance typically cut maintenance spending by 15–25% annually.

Improved Asset Lifespan

Why it matters: Critical assets like turbines and boilers cost tens to hundreds of millions to replace.

AI advantage:

Monitors stress, temperature, vibration, and operating cycles in real time.

Suggests optimal operating parameters to reduce wear.

Impact: Extending asset life by just 1–2 years can save $10–20M in capital expenditures.

Enhanced Safety for Workers

Why it matters: Emergency repairs often expose technicians to high-risk environments (hot zones, high voltage, moving machinery).

AI advantage:

Predicts issues early so repairs can be planned under safer conditions.

Reduces the need for hazardous emergency interventions.

Impact: Lower accident rates, improved regulatory compliance, and reduced workers’ compensation costs.

Optimized Spare Parts Inventory

Why it matters: Overstocking parts ties up capital; understocking leads to delays.

AI advantage:

Uses failure probability models to forecast part demand.

Aligns procurement schedules with actual asset health.

Impact: Plants can cut spare parts inventory costs by up to 30% while maintaining readiness.

Increased Energy Efficiency

Why it matters: Equipment in poor health consumes more fuel and produces less output.

AI advantage:

Detects suboptimal performance due to fouling, leaks, or wear.

Recommends tuning or cleaning before efficiency drops significantly.

Impact: Even a 1% gain in efficiency in a 500 MW plant can save millions in fuel costs annually.

Key Takeaway:

AI predictive maintenance delivers a triple win – reducing downtime, cutting costs, and boosting safety – while directly improving the bottom line.

Step-by-Step Implementation Framework for Power Plants

Adopting AI-driven predictive maintenance isn’t just about installing software – it’s a strategic transformation.

Here’s a clear, actionable roadmap for power plant operators.

Step 1. Define Objectives and KPIs

Why it matters: You need to know what success looks like before you start.

Actions:

Identify primary goals: reduce downtime, cut maintenance costs, improve safety, or boost efficiency.

Set KPIs (e.g., MTBF – Mean Time Between Failures, % reduction in emergency work orders, spare parts inventory turnover).

Pro Tip: Align objectives with both operational and financial targets so management buy-in is easier.

Step 2. Conduct Asset Criticality Assessment

Why it matters: Not all equipment deserves the same level of monitoring.

Actions:

Classify assets by impact on operations, replacement cost, and failure risk.

Prioritize critical assets like turbines, boilers, transformers, pumps.

Example: Apply AI first on assets with highest downtime cost to prove ROI quickly.

Step 3. Install or Upgrade Sensor Infrastructure

Why it matters: AI is only as good as the data it receives.

Actions:

Ensure sensors are installed for vibration, temperature, pressure, acoustic, and oil quality.

Upgrade existing systems to enable real-time data streaming.

Technical Tip: Use wireless IoT sensors for hard-to-reach or remote areas to cut cabling costs.

Step 4. Integrate Data Sources

Why it matters: Disconnected data leads to missed insights.

Actions:

Connect sensors, SCADA, DCS, and ERP systems into a unified data platform.

Standardize formats for seamless AI analysis.

Example: Use data lakes to store raw inputs, then pipeline them into AI analytics tools.

Step 5. Select the Right AI Predictive Maintenance Platform

Why it matters: The wrong tool can cause wasted investment.

Actions:

Evaluate based on asset compatibility, scalability, and ease of integration.

Consider cloud-based vs. on-premises depending on latency and security requirements.

Pro Tip: Choose platforms with explainable AI so engineers trust the system’s predictions.

Step 6. Train AI Models on Historical Data

Why it matters: AI accuracy depends on relevant past data.

Actions:

Feed years of maintenance logs, sensor readings, and failure records.

Validate models with a small-scale pilot before plant-wide rollout.

Impact: Increases prediction accuracy, reducing false alarms and missed failures.

Step 7. Set Up Alerting and Decision Protocols

Why it matters: Predictions must translate into action.

Actions:

Define thresholds for alerts (e.g., vibration amplitude, temperature rise rate).

Establish workflows for engineers to inspect, repair, or monitor flagged equipment.

Pro Tip: Integrate alerts into mobile apps so maintenance teams can respond instantly.

Step 8. Continuous Improvement and Feedback Loop

Why it matters: AI models improve with ongoing feedback.

Actions:

Regularly retrain models with new failure cases and updated operational data.

Track KPI improvements and adjust strategies accordingly.

Impact: Ensures the system stays accurate even as plant conditions change.

Key Takeaway:

The fastest ROI comes when you start small, prove value, then scale – rather than trying to implement plant-wide AI from day one.

Technical Requirements for AI Predictive Maintenance in Power Plants

For AI predictive maintenance to deliver accurate, real-time insights, the right technical foundation must be in place.

This includes hardware, software, networking, and cybersecurity components working seamlessly together.

Hardware Infrastructure

Industrial IoT Sensors

Vibration sensors for rotating equipment (turbines, pumps, fans).

Temperature sensors for bearings, transformers, and boilers.

Pressure sensors for steam systems and pipelines.

Acoustic/ultrasonic sensors for detecting leaks and mechanical stress.

Edge Devices / Gateways

Preprocess data locally to reduce bandwidth load and improve latency.

Examples: Siemens SIMATIC IoT2040, Advantech ECU series.

Server Hardware

For on-premises AI processing: multi-core CPUs, GPUs for ML model training, redundant storage.

For critical plants, deploy failover servers for zero downtime.

Condition Monitoring Equipment

Portable analyzers for offline verification and AI model calibration.

Software Stack

AI/ML Platforms

TensorFlow, PyTorch for model training.

Commercial platforms like IBM Maximo, GE Predix, Siemens MindSphere for industrial AI.

Data Management

Data lakes (e.g., AWS S3, Azure Data Lake) for raw sensor data.

Time-series databases (e.g., InfluxDB, OSIsoft PI) for continuous monitoring.

Integration Middleware

OPC UA or MQTT brokers to connect SCADA/DCS with AI systems.

Visualization Tools

Power BI, Grafana, or custom dashboards to display real-time asset health.

Network & Connectivity

High-Bandwidth Industrial Ethernet

Ensures fast transmission of high-frequency sensor data.

Wireless Protocols for IoT Sensors

LoRaWAN for long-range low-power communication.

Wi-Fi 6 or private 5G for high-bandwidth, low-latency applications.

Segmentation

Separate OT (Operational Technology) network from IT network to minimize cyber risk.

Cybersecurity Requirements

Network Security

Firewalls, intrusion detection systems (IDS), and intrusion prevention systems (IPS).

Data Encryption

End-to-end encryption (TLS 1.3) for data in motion.

AES-256 for data at rest.

Access Control

Role-Based Access Control (RBAC) for system users.

Compliance

Follow NERC CIP (North America) or IEC 62443 (international) standards.

Scalability & Redundancy

Modular System Architecture

Start small and scale to cover entire plant.

Redundant Communication Paths

Multiple network routes to avoid single point of failure.

Cloud vs. On-Premise

Cloud for scalability and analytics power.

On-premise for low-latency and higher control.

Key Takeaway:

A predictive maintenance system is only as strong as its technical backbone – poor infrastructure means inaccurate predictions and slow ROI.

For power plants, investing in robust sensors, reliable networking, scalable AI platforms, and strong cybersecurity is non-negotiable.

Data Strategy: From Collection to AI Insights

The quality, variety, and timeliness of data directly determine how well an AI predictive maintenance system can forecast failures in power plants.

A robust data strategy ensures that sensor readings, operational logs, and historical maintenance records are transformed into actionable intelligence.

Data Collection

Sensor Data

Continuous streams from vibration, temperature, pressure, and electrical sensors.

Sampling rate must match the equipment’s operational dynamics (e.g., turbines need millisecond-level sampling).

Control System Logs

SCADA/DCS event logs for operational conditions.

Maintenance History

Previous repairs, parts replacements, downtime causes.

Environmental Data

Weather conditions, humidity, and ambient temperature – crucial for outdoor equipment.

Data Integration

Protocol Converters

Use OPC UA, Modbus TCP/IP, or MQTT to unify multiple vendor systems.

Data Aggregation

Combine plant-level data with ERP systems for cost and spare parts planning.

Edge Processing

Pre-filter and compress data before sending to the cloud to reduce bandwidth usage.

Data Cleaning & Preprocessing

Outlier Detection

Remove sensor spikes due to calibration errors.

Missing Data Handling

Apply interpolation or predictive filling techniques.

Normalization

Standardize units (e.g., °C vs. °F, bar vs. psi) to avoid model confusion.

Time Synchronization

Align data from different sensors to the same timestamp for accurate correlation.

Data Storage

Time-Series Databases

InfluxDB, TimescaleDB for high-frequency monitoring.

Data Lakes

AWS S3, Azure Data Lake for raw and historical data.

Tiered Storage

Hot storage for real-time analytics, cold storage for historical trend analysis.

AI Model Training

Feature Engineering

Extract meaningful patterns from raw data (e.g., rolling averages, frequency spectra).

Model Selection

Anomaly detection models, regression models, or deep learning for complex patterns.

Continuous Learning

Retrain AI models as new data arrives to maintain accuracy.

Data Governance

Data Ownership

Clearly define whether the plant or third-party AI provider controls the data.

Compliance

Follow data privacy laws (GDPR in Europe, CCPA in California).

Access Control

Only authorized personnel should access sensitive operational data.

Key Takeaway:

The most advanced AI algorithm will fail if fed dirty, incomplete, or unstructured data.

Power plants must collect the right data, integrate it seamlessly, clean it rigorously, and use it to continuously train AI models for maximum predictive accuracy

Implementation Roadmap for AI Predictive Maintenance in Power Plants

Deploying AI predictive maintenance in a power plant is not a one-shot project – it’s a phased journey that blends technology, process change, and workforce adaptation.

Here’s a proven 6-phase roadmap for successful adoption.

Phase 1 – Initial Assessment & Goal Setting

Identify Maintenance Pain Points

Which assets cause the most downtime? (e.g., turbines, generators, transformers).

Which failures are most costly or disruptive?

Define Success Metrics

Mean Time Between Failures (MTBF) improvement.

Reduction in unplanned downtime.

Maintenance cost savings.

Stakeholder Engagement

Involve plant managers, maintenance engineers, IT, and finance early to align objectives.

Phase 2 – Infrastructure Readiness

Sensor Audit

Check existing sensor coverage and upgrade where necessary.

Connectivity Assessment

Ensure stable SCADA/DCS integration and high-bandwidth data transfer.

Edge/Cloud Decision

Decide whether AI processing will be on-site (edge computing) or in the cloud.

Phase 3 – Data Preparation

Data Inventory

Gather historical sensor readings, maintenance logs, and failure records.

Data Cleansing

Remove noise, handle missing values, and normalize formats.

Data Integration

Create a unified data pipeline from multiple systems (SCADA, CMMS, ERP).

Phase 4 – Pilot Project

Asset Selection

Start with high-value, high-failure assets (e.g., main steam turbine).

Model Training

Use historical and live data to train AI models.

KPIs Tracking

Monitor early results: prediction accuracy, false alarms, downtime reduction.

Iteration

Refine the model before scaling up.

Phase 5 – Full-Scale Deployment

System Integration

Connect AI output to the CMMS for automated work order creation.

Cross-Asset Monitoring

Expand AI coverage to all critical plant equipment.

Maintenance Workflow Optimization

Shift from scheduled to condition-based interventions.

Phase 6 – Continuous Improvement

Model Retraining

Update AI algorithms regularly with new data to maintain accuracy.

Operational Feedback Loop

Maintenance team feedback helps fine-tune alerts and recommendations.

Performance Audits

Conduct quarterly reviews of ROI, downtime savings, and asset reliability improvements.

Key Takeaway:

A successful AI predictive maintenance program is built on clear goals, solid infrastructure, clean data, and gradual scaling.

Starting small with a pilot reduces risk, while continuous feedback ensures long-term reliability and cost efficiency.

Case Studies: AI Predictive Maintenance Success in Power Plants

Seeing AI predictive maintenance in action helps turn the concept from an abstract idea into a proven business case.

Here are three real-world style scenarios showing how power plants have achieved measurable gains.

Case Study 1 – Gas-Fired Power Plant (USA)

Challenge:

Frequent unplanned shutdowns due to turbine bearing failures, costing $150,000 per incident and averaging 6 incidents/year.

AI Approach:

Installed vibration and temperature sensors on critical turbine bearings.

AI model trained on 3 years of historical SCADA data and failure logs.

Deployed edge computing to analyze data in near-real time.

Results:

Detected bearing degradation 20 days before potential failure.

Reduced unplanned shutdowns by 83%.

Annual cost savings: ~$750,000.

Maintenance scheduling shifted from every 3 months to only when needed.

Key Takeaway:

Early detection of bearing wear significantly extends turbine life and eliminates emergency repairs.

Case Study 2 – Coal-Fired Power Plant (India)

Challenge:

Boiler tube leaks causing multi-day outages and costly repairs.

AI Approach:

Implemented thermal imaging and pressure sensors.

AI model identified subtle patterns in heat distribution and steam pressure that signaled leaks up to 10 days in advance.

Results:

Outage duration reduced from 5 days to 1 day.

Annual savings on downtime: $1.2 million.

Reduced boiler tube failure frequency by 40% in the first year.

Key Takeaway:

AI-driven anomaly detection turns catastrophic failures into controlled maintenance events.

Case Study 3 – Hydroelectric Power Plant (Norway)

Challenge:

Unpredictable generator winding insulation failures leading to sudden stoppages.

AI Approach:

Collected insulation resistance data, temperature, and humidity readings.

Used AI to predict insulation degradation rates.

Integrated system alerts directly into the plant’s maintenance scheduling platform.

Results:

Predicted insulation failure 15 days earlier than traditional methods.

Achieved 98% accuracy in predicting high-risk equipment.

Saved ~$500,000 annually in repair costs and lost production.

Key Takeaway:

AI predictive maintenance empowers hydro plants to plan downtime strategically, avoiding peak demand losses.

Why These Case Studies Matter

Cross-Technology Proof: AI works across gas, coal, and hydro plants.

Scalable Impact: Small pilot programs deliver big returns when scaled.

Hard Numbers: Clear financial ROI makes it easier to secure budget approval.

Future Outlook & Emerging Trends in AI Predictive Maintenance for Power Plants

AI predictive maintenance has already proven its value in cost savings, reliability, and operational safety, but the next decade will bring even more transformative changes.

Here’s what’s coming – and why power plant operators who act early will have a serious competitive edge.

Integration with Digital Twins

What’s Coming:

Power plants will create digital replicas of their turbines, boilers, and generators.

These digital twins will simulate every operational scenario, allowing AI to test maintenance strategies before they are applied in the real world.Impact:

Predict failures before they happen in reality.

Optimize maintenance schedules with near-perfect accuracy.

Reduce trial-and-error in costly equipment interventions.

AI + IIoT Sensor Fusion

What’s Coming:

Predictive models will combine data from hundreds of sensor types – vibration, thermal, acoustic, electrical signature, and even satellite weather data – into a single diagnostic dashboard.Impact:

Detect multi-factor failure causes (e.g., temperature + vibration + humidity).

Increase predictive accuracy from 85% to 98%.

Lower false positives, meaning maintenance teams focus only on real threats.

Edge AI for Real-Time Decision-Making

What’s Coming:

Processing will happen right at the equipment site, eliminating latency from cloud computing.Impact:

Enable split-second protective actions for high-speed rotating equipment.

Maintain predictive capabilities even in remote or low-connectivity locations.

Reduce dependence on central IT infrastructure.

AI-Powered Autonomous Maintenance

What’s Coming:

Maintenance robots and drones will be guided by AI to perform inspections and minor repairs autonomously.Impact:

Minimize human exposure to hazardous environments.

Reduce downtime by conducting inspections without stopping production.

Perform overnight or emergency repairs without waiting for human crews.

Predictive + Prescriptive Maintenance

What’s Coming:

The shift from “This will fail soon” to “Here’s the exact step to fix it”.

AI will not only predict issues but recommend precise maintenance actions, required parts, and manpower.Impact:

Eliminate guesswork in troubleshooting.

Standardize maintenance quality across shifts and locations.

Shorten Mean Time to Repair (MTTR) by up to 60%.

Sustainability and Carbon Reduction

What’s Coming:

Predictive maintenance will integrate with energy optimization algorithms to cut fuel waste and emissions.Impact:

Align maintenance with net-zero emission goals.

Extend the lifespan of equipment, reducing manufacturing-related carbon footprints.

Provide regulators with compliance-ready operational data.

AI as a Service (AIaaS) for Power Plants

What’s Coming:

Smaller power plants will access predictive maintenance tools through subscription-based AI platforms.Impact:

Lower upfront investment costs.

Democratize access to high-level analytics.

Allow even small operators to compete with large utilities on operational efficiency.

Key Takeaways for Power Plant Operators

Act Early: Plants that adopt AI predictive maintenance now will gain a data advantage over late adopters.

Think Big Picture: This isn’t just about fixing equipment – it’s about reshaping asset management strategy for the next decade.

Start Small, Scale Fast: Begin with critical assets, prove ROI, then roll out plant-wide.

Final Thought:

AI predictive maintenance is no longer a futuristic concept – it’s the new baseline for competitive power generation.

The operators who invest now will not only cut costs but also secure long-term resilience in an increasingly unpredictable energy market.