- Introduction: Beyond Traditional Automation

- Why AI Makes Robotics Smarter

- Core Benefits: Precision, Speed & Adaptability

- AI Technologies Powering Modern Robots

- Real-World Case Studies Across Industries

- Implementation Roadmap: From Pilot to Scale

- Challenges and How to Overcome Them

- Future Trends: Edge AI, GenAI & Collaborative Robots

- Comparative Framework: Traditional vs AI Robotics

- Conclusion & Strategic Takeaways

- FAQs

Introduction: Beyond Traditional Automation

For decades, industrial robots simply repeated pre-programmed tasks – capable, but inflexible. Today, AI-powered robotics push this further: they learn, adapt, and optimize in real-time. Whether handling delicate electronics or lifting heavy loads on offshore rigs, these robots are reshaping productivity altogether.

Why AI Makes Robotics Smarter

- Adaptive Intelligence: Robots adjust grip, speed, and trajectory in response to live feedback.

- Conditional Autonomy: They can decide whether to proceed, wait, or alert human intervention.

- Continuous Learning: Each job refines the performance of the robotic model.

Location oil rigs or remote drilling sites benefit when robots can respond autonomously – no waiting on cloud commands.

Core Benefits: Precision, Speed & Adaptability

Precision

AI precision brings accuracy down to microns – ideal for electronics, semiconductor assembly, or weld seams. Robots can consistently place tiny components or apply precise finishing tolerances.

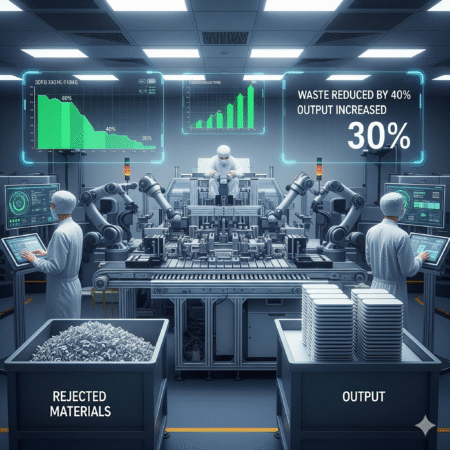

Speed

AI optimizes efficiency by:

- shortening cycle times

- minimizing repositioning or reloading delays

- reducing scrap through real-time defect detection

In one automotive plant, AI robots cut cycle time by 22% and lowered defect rates by 18%.

Smart Adaptability

If a sensor detects part misalignment, AI can initiate a corrective path program – even mid-cycle. This adaptability reduces inspection downtime and improves line throughput.

AI Technologies Powering Modern Robots

| AI Technology | Role in Robotics |

|---|---|

| Computer Vision | Recognizes parts, guides real-time movement |

| Deep Learning | Classifies defects or optimizes grasp strategies |

| Reinforcement Learning | Learns optimal motions via feedback trials |

| Sensor Fusion | Merges lidar, ultrasonic, vision sensors |

| NLP Interfaces | Enables voice commands or human-robot interaction |

These technologies combine to let robots operate safely and intelligently alongside human workers.

Real-World Case Studies Across Industries

Automotive Manufacturing

Ford used AI-guided robotic arms to detect micro-cracks in engine castings – catching defects 3x faster than human inspectors.

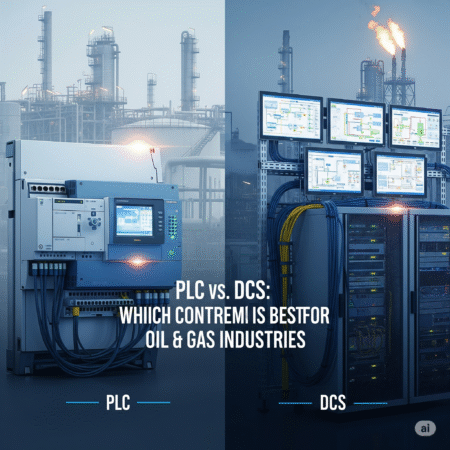

Oil & Gas

Shell Deploys autonomous crawlers with AI vision to inspect pipeline welds. Early corrosion detected via drone imagery prevented potential environmental disasters.

Logistics / FMCG

Amazon’s Kiva robots use AI navigation to retrieve inventory dynamically, adapting paths in real time to avoid congestion and hazards.

Pharmaceuticals

In cleanrooms, AI-powered robots transfer sterile components under real-time motion planning – minimizing contamination risk and maximizing precision.

Implementation Roadmap: From Pilot to Scale

- Assess Asset Readiness: Identify high-frequency or high-value tasks ideal for robotic automation.

- Pilot Deployment: Begin with one robot line, integrate feedback loops, monitor KPIs.

- Data Infrastructure: Deploy sensors and edge computing to support real-time inference.

- AI Model Training: Use historical & live sensor data to train and validate.

- Scale & Iterate: Expand to other lines or sites, replicate setup and fine-tune AI models.

Key KPI set: downtime reduction, yield improvement, energy usage, and unit cost.

Challenges and How to Overcome Them

- Cost & CapEx: Start with ROI-focused pilot projects.

- Integration with Legacy Systems: Use SCADA and middleware solutions for interoperability.

- Cybersecurity: Secure robotic networks with zero trust, regular audits, and encrypted communication.

- Skills Gap: Upskill engineers on robotics/AI; start internal robotics center of excellence (CoE).

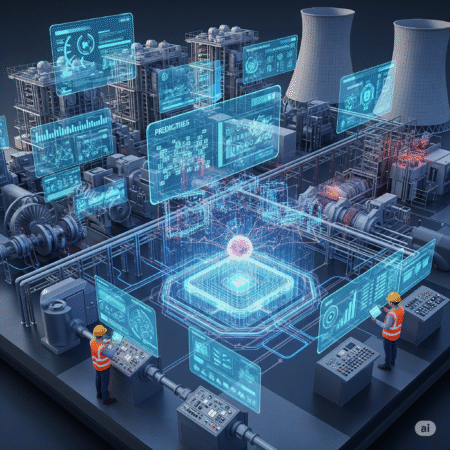

Future Trends: Edge AI, GenAI & Collaborative Robots

- Edge AI robots process commands internally – minimizing latency and ensuring reliability.

- Generative AI designs optimized robot tasks, parts, and trajectories.

- Cobots: Human-robot teams collaborate seamlessly using gesture and voice control interfaces.

Meetings, repairs, and even complex paths may soon be inherently adaptive – robots crafting their own logic via GenAI.

Comparative Framework: Traditional vs AI Robotics

A side-by-side comparison:

| Feature | Traditional Robots | AI-Powered Robots |

|---|---|---|

| Task Programming | Rigid, manual | Adaptive, automated |

| Quality/Precision | Fixed tolerances | Dynamic real-time adjustments |

| Downtime Sensitivity | High – manual error recovery | Self-correcting, fewer interruptions |

| Scalability | Manual redeployment | Model-based replication |

| Human Interaction | Limited | Collaborative & intuitive |

This demonstrates why AI robotics is clearly the next-gen standard.

Conclusion & Strategic Takeaways

AI-powered robotics isn’t just automation – it’s cognitive automation.

If you’re aiming for productivity gains, precision improvements, or enhanced resilience, robotics with AI is now a strategic necessity – especially for manufacturers and automation-heavy industries in US, UK, and Canada.

Approach methodically, measure KPIs early, scale on success.

FAQs

Q1: Can AI-powered robots adapt to multiple product variants?

Yes – with machine learning vision models, robots can switch tasks dynamically.

Q2: What’s the fastest ROI window?

Depends on complexity, but many factories see ROI within 12 months.

Q3: Are AI robots safe to operate around humans?

Yes – modern AI cobots include motion sensors and emergency stop features for safe coexistence.

Want to stay updated on AI robotics, industrial AI, and automation strategy?

👉 Subscribe to EngineerDaily.News for weekly expert insights, tools reviews, and use-case breakdowns delivered straight to your inbox.