- What is an AI-Powered Digital Twin?

- How Digital Twins Enhance Industrial Efficiency

- AI’s Role in Real-Time Monitoring and Decision-Making

- Use Cases in Key Industries

- AI and Predictive Maintenance

- Challenges and Considerations

- How to Implement AI-Powered Digital Twins

- The Future of AI Digital Twins in Industry

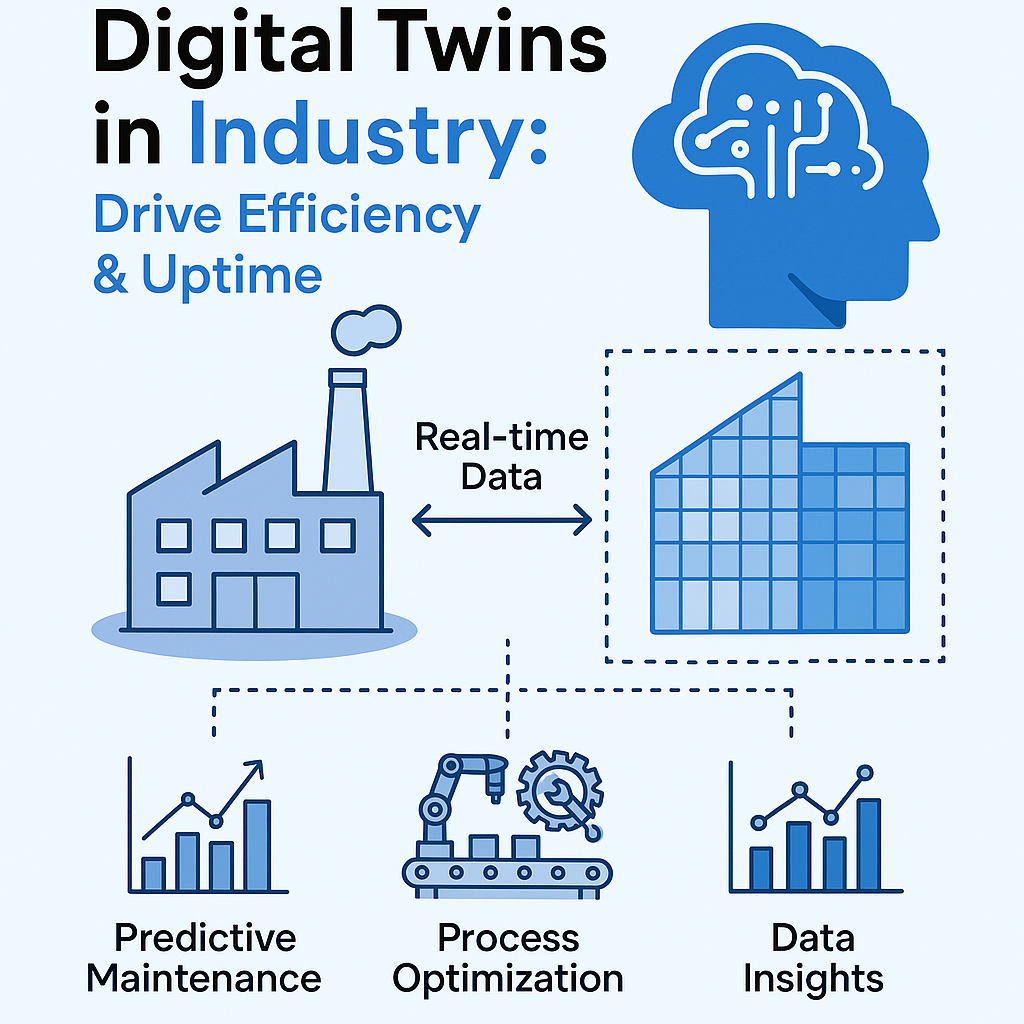

What is an AI-Powered Digital Twin?

A Digital Twin is a real-time virtual replica of a physical asset, process, or system. When combined with Artificial Intelligence, it transforms into a smart, self-learning, and predictive tool.

Unlike traditional digital twins, AI-powered versions continuously learn from real-world data using machine learning, adapt to changes, and provide optimization suggestions without human intervention.

Example: In an oil refinery, AI-enabled twins of pumps or valves not only replicate their performance but also predict failures days in advance, helping engineers act before problems escalate.

How Digital Twins Enhance Industrial Efficiency

AI-powered digital twins revolutionize how factories operate by:

- Reducing Downtime: Early warnings allow preventive actions.

- Optimizing Performance: Suggesting real-time adjustments to parameters.

- Improving Product Quality: By analyzing process variables and detecting anomalies.

- Enabling Remote Monitoring: Ideal for distributed assets and offshore platforms.

Learn more about Edge AI in Industrial Automation – where AI at the edge complements digital twin deployment.

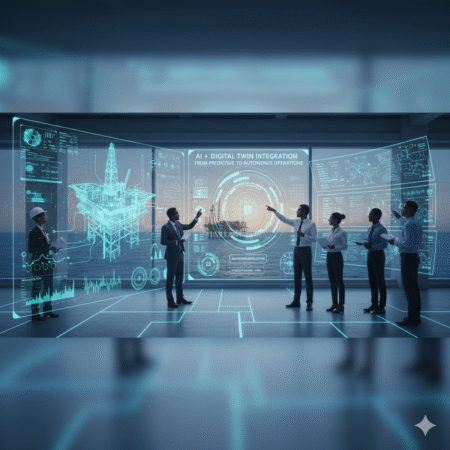

AI’s Role in Real-Time Monitoring and Decision-Making

AI integrates advanced analytics, real-time sensor input, and machine learning to:

- Analyze Sensor Data: Temp, pressure, vibration, flow — all continuously monitored.

- Make Autonomous Decisions: Adjust valves, trigger alarms, or notify technicians.

- Flag Anomalies Early: Identifying patterns unseen by human eyes.

Case Insight:

In a steel plant, AI digital twins detected subtle shifts in furnace temperature, which prevented equipment overheating and reduced energy use by 12%.

Use Cases in Key Industries

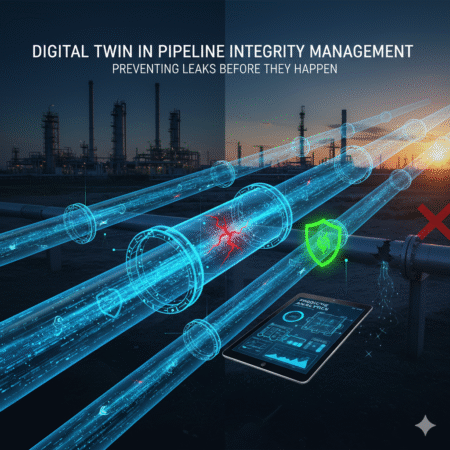

Oil & Gas:

- Monitor compressors, turbines, and pipelines in real-time.

- Predict corrosion, fatigue, and equipment failure.

Manufacturing:

- Virtual simulation of assembly lines.

- Improve throughput and quality control dynamically.

Energy:

- Model grid behavior using AI + Digital Twins.

- Optimize load balancing and integrate with renewables.

Aerospace:

- Aircraft component lifecycle monitoring.

- Optimize maintenance schedules with zero unplanned failures.

AI and Predictive Maintenance

This is one of the strongest applications. Here’s why:

- Traditional preventive maintenance is time-based. AI makes it condition-based.

- It analyzes historical + real-time data to predict component life.

- Automatically schedules interventions only when needed, cutting costs drastically.

Example:

One automotive factory saved over $2.5M/year by reducing unplanned downtime via AI-twin-powered maintenance optimization.

Challenges and Considerations

Let’s be honest — it’s powerful, but not plug-and-play.

- Data Quality Issues: Inconsistent, noisy sensor data leads to unreliable twins.

- Integration Complexity: Connecting legacy equipment and new AI platforms is non-trivial.

- Cybersecurity Risks: Digital twins are connected — and that opens vulnerability.

- Skill Gaps: Teams must be trained to interpret AI outputs effectively.

Tip: Start small — deploy AI twins on critical assets first before scaling.

How to Implement AI-Powered Digital Twins

Step-by-Step Roadmap:

- Define Objectives: What assets or processes will be digitized?

- Assess Data Availability: Is the sensor infrastructure sufficient?

- Select the Right Platform: Azure Digital Twins, Siemens, GE Predix, etc.

- Build the Model: Use physics-based models + ML.

- Train the AI Engine: Feed historical + live data.

- Test and Optimize: Pilot runs, feedback loops, recalibration.

- Scale Up: Move from one machine → entire plant.

The Future of AI Digital Twins in Industry

Expect AI twins to evolve into:

- Self-healing systems (auto-diagnose & fix)

- Fully autonomous plants (human-out-of-the-loop)

- Integrated platforms connecting supply chain, maintenance, and quality control

Industries that adopt early will outperform peers in agility, cost, and sustainability.