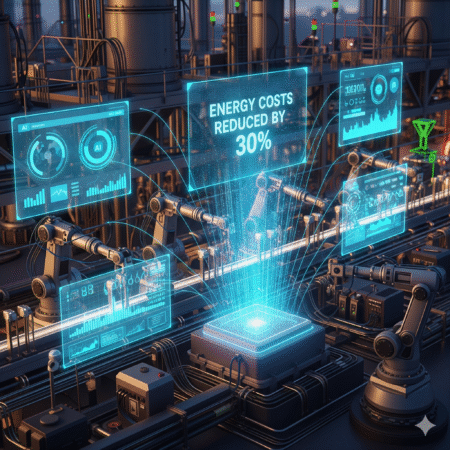

- Introduction: Why Energy Costs Are Bleeding Industrial Profits

- Where Energy Gets Wasted in Industrial Plants

- How AI Detects Hidden Energy Inefficiencies

- Predictive Energy Management: Scheduling & Load Shifting

- AI-Driven Process Optimization

- Integrating AI with Building & Facility Systems

- Real-World Case Studies: Who’s Saving Big

- Overcoming Data, Skills & Culture Barriers

- ROI Analysis – When the Savings Outweigh the Costs

- The Road to 2030: Forecasts & Scenarios

- Conclusion – Why AI Is Your Fastest Route to Lower Energy Costs

Introduction: Why Energy Costs Are Bleeding Industrial Profits

Let’s be real – in 2025, energy is no longer just a “utility expense” for industrial plants. It’s a profit killer. Whether you’re running a food processing facility in the US, a steel mill in Canada, or a chemical plant in the UK, one thing is true: energy costs are eating away at your margins faster than ever before.

For decades, energy was cheap, stable, and predictable. That’s why most industrial plants were designed for maximum output, not maximum efficiency. Oversized motors, aging chillers, inefficient compressors – nobody questioned them, because electricity and gas were just a small line item. But the market has changed dramatically. Between supply chain disruptions, geopolitical tensions, and aggressive climate policies, industrial energy prices have become volatile and brutally expensive. Even a 10% spike in energy prices can wipe out 50% of a plant’s net margin. That’s how fragile things are now.

And here’s the kicker: most plants don’t even know where their energy is going. Traditional audits and energy reviews give you static snapshots, often done once every year or two. They can’t capture daily or hourly fluctuations, nor can they spot subtle patterns of waste. So while you’re waiting for your annual energy report, your plant could be silently leaking tens of thousands of dollars every month.

That’s why AI has become the new secret weapon for industrial leaders who are serious about controlling costs. AI-driven energy management platforms can plug into your existing sensors, SCADA, or building management systems and start learning how your plant consumes power – in real time. Unlike humans, AI can crunch millions of data points per day, recognize patterns, and alert you to inefficiencies as they happen.

Think about what that means in practice:

- Detecting when a compressor is short-cycling at 2 AM on weekends

- Predicting when your peak demand will hit next week so you can shift production schedules

- Automatically optimizing setpoints for HVAC, pumps, or chillers based on real-time weather and load

And the payoff? Plants that have implemented AI are reporting energy cost reductions of 15–30% within just 6–12 months. In a low-margin industry, that can be the difference between survival and collapse.

Bottom line: If you’re still treating energy as a fixed cost, you’re already behind. Energy is now one of the biggest controllable costs in industrial operations – and AI is the fastest way to take control. In the rest of this guide, we’ll break down exactly how energy gets wasted, how AI fixes it, and how you can start capturing those savings right now.

Where Energy Gets Wasted in Industrial Plants

Here’s the uncomfortable truth: most industrial plants are leaking energy like a cracked pipeline – and they don’t even know it. You can’t fix what you can’t see, and for decades, plants have been flying blind when it comes to energy visibility.

Let’s break down where the biggest energy leaks usually happen – and why they go unnoticed.

Inefficient Equipment Operations

Old, oversized, or poorly maintained equipment is often the number one energy hog.

- Motors that run at full speed even when loads are light

- Compressors left idling during production downtime

- Chillers operating with clogged filters and poor setpoint control

This happens because traditional control logic is static – it doesn’t adapt. As a result, equipment consumes 10–25% more energy than necessary, silently burning cash every hour they run.

Poor HVAC and Process Heating/Cooling Control

HVAC systems, process heaters, and chillers often run 24/7 regardless of actual demand. This is especially brutal in large facilities where climate control is a major load.

Energy is wasted through:

- Lack of dynamic scheduling

- No real-time load balancing

- Poor insulation and air leaks

In some plants, HVAC alone accounts for 30–40% of total electricity usage – yet most systems are still manually operated.

Idle & Phantom Loads

Equipment that stays powered on even when not in use – think conveyor belts, pumps, fans, lighting – creates phantom energy costs.

It seems small, but across hundreds of devices, this adds up to millions of kilowatt-hours annually.

These loads are hard to track without granular real-time monitoring.

Inefficient Scheduling & Peak Demand Spikes

One of the most overlooked sources of energy waste is poor production scheduling. Running high-load processes during peak tariff hours triggers demand charges, which can be 30–50% of your electricity bill.

Without predictive insight, plants often hit these peaks unintentionally, leaving tens or even hundreds of thousands of dollars on the table each year.

Summary Table – Common Energy Waste Sources

| Waste Source | Typical Impact on Energy Bill | Why It’s Hard to Catch |

|---|---|---|

| Inefficient equipment | +10–25% | Static control logic, aging assets |

| HVAC/process heating/cooling | +20–40% | Lack of load-based control |

| Idle/phantom loads | +5–15% | Hidden in background operations |

| Peak demand spikes | +10–30% | No predictive scheduling |

Bottom line: energy waste is everywhere – and invisible.

Until you can see in real time where every watt is going, you can’t control it. This is exactly where AI changes the game – but first, we need to understand how it actually works.

How AI Detects Hidden Energy Inefficiencies

Fokus: IoT sensor + data logging, pattern recognition & anomaly detection, energy baselining otomatis, real-time alert dari AI

AI’s superpower isn’t just crunching numbers – it’s seeing patterns that humans can’t, especially across millions of data points that industrial plants generate every day. This is exactly how AI reveals hidden energy inefficiencies that quietly drain budgets.

Let’s break down how it works.

IoT Sensors + High-Resolution Data Logging

AI needs granular data to work. That’s why modern energy AI platforms deploy IoT sensors across:

- Motors, pumps, compressors (real-time kWh, load, temperature, vibration)

- HVAC & chillers (airflow, temperature delta, runtime)

- Steam & compressed air lines (pressure, flow rate, leak detection)

Instead of monthly utility bills, plants now get second-by-second data streams.

This is the raw material AI needs to detect inefficiency early – often weeks before it shows up on the bill.

Pattern Recognition & Anomaly Detection

AI thrives on recognizing normal vs abnormal.

Once it learns the plant’s baseline behavior, it flags unusual consumption patterns like:

- Motors drawing excess current while under light load

- Boilers running during non-production hours

- Sudden spikes in compressed air demand (potential leak)

This is where traditional monitoring fails – humans simply can’t watch thousands of variables at once, but AI can do it 24/7 with no fatigue.

Automatic Energy Baselining

Energy baselining used to be tedious – spreadsheets, manual data pulls, and static benchmarks.

AI automates this by:

- Building dynamic energy models for each asset

- Adjusting baselines automatically based on production volume, shift schedules, and weather

- Recalculating targets daily as new data flows in

This gives you real-time performance vs expected – instead of waiting for end-of-month surprises.

Real-Time Alerts from AI

When AI detects an anomaly, it doesn’t just log it – it sends actionable alerts:

- “Motor #17 drawing 25% above expected current”

- “Steam pressure drop indicates possible leak in Line B”

- “Compressor running idle for 2 hours – shut down to save energy”

These alerts let maintenance teams intervene before waste compounds into big costs.

Quick Reference Table

| AI Capability | What It Does | Impact on Energy Waste |

|---|---|---|

| IoT + data logging | Captures granular energy data | Enables early detection |

| Pattern recognition | Detects abnormal behavior vs baseline | Finds hidden inefficiencies |

| Automated baselining | Continuously updates energy targets | Keeps operations optimized |

| Real-time alerts | Warns about anomalies instantly | Prevents prolonged energy loss |

Bottom line: AI acts like a 24/7 energy detective – constantly scanning your plant for invisible leaks, idle equipment, or sudden spikes that humans would miss.

This is the foundation of AI-driven energy savings: before you optimize, you must first see the invisible waste.

Predictive Energy Management: Scheduling & Load Shifting

Energy savings aren’t just about fixing leaks or optimizing machines – they’re also about timing.

Industrial plants often pay penalties for consuming energy during peak pricing hours. That’s where AI steps in: by predicting demand and reshaping energy usage schedules, it can slash energy bills without touching your hardware.

Read More: AI-Powered Predictive Maintenance in Oil & Gas Complete Guide (2025-2030)

Let’s break this down.

Forecasting Energy Demand with AI

Traditional energy planning uses historical averages. AI goes beyond that by analyzing:

- Production schedules

- Weather patterns (which impact HVAC loads)

- Real-time machine status

- Electricity market pricing trends

With this data, AI can predict next-day or even next-hour energy demand at a granular level.

Instead of reacting to spikes, plants can proactively plan which machines to run and when – avoiding surprise surcharges.

Example: A steel plant used AI forecasting to predict daily power demand within ±2%. They shifted heavy loads to off-peak hours and cut their energy bill by 18%.

Machine Scheduling Optimization

Once demand is predicted, AI optimizers can orchestrate when each machine should run for maximum cost efficiency.

It evaluates:

- Machine energy profiles

- Production deadlines

- Operator shifts

- Maintenance windows

Then it builds a smart production schedule that balances output and energy price.

This reduces overlapping peaks – when too many high-load machines run together and spike consumption.

Load Shifting to Avoid Peak Pricing

Load shifting is about moving energy-intensive tasks to cheaper time windows.

AI makes this easy because it:

- Continuously tracks real-time utility rates

- Knows which machines can be paused or delayed without hurting production

- Automatically suggests rescheduling jobs to off-peak hours

The result is same output, lower energy cost.

This is especially powerful in regions with time-of-use tariffs or demand charges.

Direct Impact on Energy Bills

AI-driven scheduling and load shifting hit where it matters: the bottom line.

Here’s how it changes the game:

| Strategy | What It Does | Impact on Cost |

|---|---|---|

| AI demand forecasting | Predicts energy needs accurately | Avoids surprise spikes |

| Smart machine scheduling | Aligns usage with low-tariff periods | Flattens peak loads |

| Load shifting | Moves heavy tasks to off-peak hours | Lowers average energy rate |

Plants that adopt predictive energy management often see 10–25% immediate savings on utility bills – without replacing a single motor or compressor.

Bottom line: Predictive energy management gives plants a time advantage. Instead of reacting to energy costs, they play the market like a chess master, using AI to position their energy loads at the cheapest times.

AI-Driven Process Optimization

Let’s get real – the biggest energy drains inside industrial plants often hide deep within the production process itself. You can upgrade lighting, patch air leaks, and fine-tune HVAC all day long, but if your core process equipment is running at suboptimal settings, you’re still burning cash. This is where AI-driven process optimization becomes a true game-changer.

Unlike traditional control strategies that rely on static setpoints and periodic manual tuning, AI thrives in dynamic, noisy environments. It doesn’t just automate – it learns. By continuously analyzing sensor data from every corner of your plant (temperature, pressure, flow rates, power draw, etc.), AI can detect subtle inefficiencies that human engineers or even advanced SCADA systems usually miss.

Fine-tuning Parameters for Energy Efficiency

AI models can run thousands of micro-simulations per second, adjusting control parameters like feed rate, air/fuel ratios, and pressure setpoints to hit that sweet spot of maximum output with minimum energy. Instead of waiting for monthly performance reviews or audits, plants get a real-time “energy autopilot” that self-corrects whenever the process drifts off target.

Imagine a cement kiln operating slightly hotter than needed, or a chemical reactor running with a richer mix than required. Those small deviations might seem harmless day to day, but over a year, they translate to hundreds of thousands of dollars in wasted energy. AI eliminates this bleed by continuously nudging the process back to its most efficient state.

Closed-Loop Control Using Reinforcement Learning

Reinforcement learning (RL) takes this even further. While traditional AI models make predictions, RL-based systems take actions and learn from the results. Think of it as a super-fast digital apprentice that tries different settings, measures the energy impact, and quickly learns what works best.

For example, a compressor network might have dozens of possible on/off configurations. An RL agent can explore them all, identify the lowest-energy pattern that still meets production demand, and then lock it in automatically – without risking downtime. Over weeks, it keeps improving as conditions change (ambient temperature, raw material quality, maintenance cycles, etc.).

Real-World Impact

Some plants report 10–15% reductions in energy use just from AI-driven optimization of furnaces, compressors, or chillers. This isn’t just about shaving costs – it also boosts equipment lifespan and production stability. Less thermal cycling, fewer overloads, fewer emergency shutdowns.

Bottom line: if you want to slash energy costs fast, don’t just look at “support systems” – point AI at your core processes. That’s where the biggest savings are quietly hiding, and where early adopters are pulling way ahead of the pack.

Integrating AI with Building & Facility Systems

Here’s the thing most plant managers overlook: while production lines hog the spotlight, building and facility systems quietly eat up a massive chunk of your energy bill. HVAC, lighting, chilled water, and building management systems (BMS) are often running on fixed schedules or outdated logic. The result? They waste power every single day – heating, cooling, and lighting spaces that don’t even need it.

AI flips this script by making your facility systems adaptive and context-aware. Instead of rigid schedules, AI algorithms learn how your buildings actually behave, how weather and occupancy patterns shift, and how all these factors influence energy use. The payoff? Continuous optimization that trims costs without sacrificing comfort or safety.

AI for HVAC, Lighting, and Chilled Water Systems

Traditional HVAC systems are notorious for “fighting themselves” – simultaneously heating and cooling adjacent zones, blasting full power during off-peak hours, or ignoring outdoor temperature swings.

AI-based building energy management systems plug into your existing BMS, ingest sensor data (temperature, humidity, CO₂ levels, occupancy sensors), and dynamically adjust setpoints in real time. Lighting can dim automatically when natural daylight is sufficient, while chilled water systems throttle output based on actual cooling demand rather than a fixed load estimate.

Imagine cutting HVAC runtime by 25% just by letting AI recognize that a certain wing of the plant is usually empty after 5 PM. That’s instant savings – no capital upgrade needed.

Adaptive Control: Learning from Energy Use Patterns

AI thrives on pattern recognition. Over weeks, it can spot hidden trends in your facility’s energy usage: maybe your compressors always spike 15 minutes before shift change, or your chilled water demand drops sharply on cloudy days.

With adaptive control, AI doesn’t just react – it anticipates. It learns how your systems behave under different conditions and starts proactively adjusting controls to minimize waste. This is the secret sauce behind some of the biggest energy cost reductions in modern industrial campuses.

Long-Term Savings Impact

The real magic here is compounding gains. While optimizing production equipment can deliver big immediate wins, AI-led facility optimization steadily chips away at the “background load” year after year.

Companies that integrate AI into building systems often report 10–20% lower overall energy spend just from smarter HVAC, lighting, and chilled water management. That’s money saved every single month – and it keeps improving as the AI gets smarter.

Bottom line: your facility systems are low-hanging fruit. Plug AI into them, and you’ll unlock savings you didn’t even realize were on the table.

Real-World Case Studies: Who’s Saving Big

Here’s where it gets exciting – AI isn’t just theory anymore. Around the world, industrial plants are already using AI to slash their energy bills by double-digit percentages. These aren’t small pilot tests; they’re full-scale deployments saving millions of dollars annually. Let’s look at three powerful examples.

Chemical Plant: Cutting 20% Energy Use

A large European chemical manufacturer rolled out an AI-driven energy management system across multiple production lines.

- What they did: Installed IoT sensors on pumps, motors, and chillers to track real-time energy consumption and feed it into an AI platform.

- How it worked: The AI spotted hidden inefficiencies like oversized motors running at partial loads, and coordinated schedules so equipment only ran when truly needed.

- The result: A 20% drop in overall electricity consumption in the first year, worth millions in annual savings, with zero impact on production output.

Automotive Plant: Millions Saved Each Year

An automotive assembly plant in the U.S. faced sky-high electricity bills from around-the-clock operations.

- What they did: Deployed AI scheduling software tied to production planning and local energy tariffs.

- How it worked: The AI shifted non-critical energy loads (like paint shop air compressors and robotic welding preheating) to off-peak hours and reduced idle equipment power draw between shifts.

- The result: Over $3 million in annual energy cost reductions, plus a 12% improvement in overall equipment efficiency.

Food Manufacturer: Smarter Load Control

A global food processing company struggled with fluctuating energy use from refrigeration systems and baking lines.

- What they did: Integrated AI-based load control into their facility energy management system.

- How it worked: The AI dynamically balanced power use between ovens, chillers, and packaging lines, based on production demand forecasts and utility price signals.

- The result: Achieved 15% lower peak demand charges and smoother energy loads, while extending equipment lifespan thanks to fewer sudden power surges.

The takeaway? AI-driven energy optimization works at scale. These companies didn’t just trim costs – they improved operational resilience and freed up capital for growth.

Overcoming Data, Skills & Culture Barriers

Here’s the hard truth: AI won’t magically slash your energy costs if your organization isn’t ready for it.

Many industrial plants fail not because the tech is bad – but because they run into hidden barriers around data quality, skills, and workplace culture. Let’s break these down and see how to overcome them.

Barrier #1: Data Silos and Inconsistent Quality

AI thrives on data – but most plants have energy data scattered across multiple systems: SCADA, BMS, CMMS, spreadsheets, even handwritten logs. These silos make it impossible for AI to see the full energy picture.

Fix it:

- Deploy an energy data platform that integrates IoT sensor feeds, utility meters, and operational logs into one cloud dashboard.

- Standardize data formats, timestamps, and naming conventions so AI can analyze data consistently.

- Start with high-energy-load equipment first (compressors, chillers, furnaces) to prove value quickly.

Barrier #2: Lack of AI & Energy Analytics Skills

Most operations teams know their machines inside out – but not machine learning. This skills gap slows down AI projects or makes them dependent on expensive external consultants.

Fix it:

- Launch targeted upskilling programs: short, hands-on training on AI tools for energy engineers, maintenance staff, and operators.

- Create cross-functional “energy squads” combining data scientists and plant engineers, so the AI models align with real-world constraints.

- Start with vendor-supported platforms that have low-code interfaces to reduce technical barriers.

Barrier #3: Cultural Resistance from Operations Teams

Even when the tech works, AI initiatives can hit a wall if frontline teams see them as a threat or extra workload.

Fix it:

- Begin with “quick win” pilot projects that deliver visible energy savings within 2–3 months.

- Communicate clearly that AI is an assistant, not a replacement – it helps operators work smarter, not harder.

- Recognize and reward teams who adopt AI-driven energy practices, to build momentum.

Bottom line: You can’t just plug in AI – you have to prepare your people and your data.

Once these barriers are removed, energy-saving AI systems can scale across the plant and deliver compounding ROI.

ROI Analysis – When the Savings Outweigh the Costs

Here’s the brutal truth: No one will greenlight your AI energy project unless the ROI math checks out.

Executives don’t care about how futuristic it sounds – they care about how fast it pays for itself.

Let’s break this down like Neil Patel would: simple, straight to the point, and numbers-driven.

The True Cost of AI Implementation

Implementing AI for energy optimization isn’t just “buying software.” It’s an end-to-end transformation. Expect costs to include:

- IoT sensors and smart meters for real-time energy data collection

- Edge devices or industrial PCs to run on-site AI models

- Cloud analytics subscriptions to crunch data and generate insights

- Integration with your SCADA/BMS/ERP systems

- Training and change management for your operations team

For a mid-sized industrial plant, you’re typically looking at $250K–$1M in upfront investment, depending on scope.

Yes, it sounds steep – but keep reading, because this is where it gets interesting.

Payback Period: How Fast It Pays for Itself

Energy efficiency projects have one of the fastest ROIs in the industrial world. Why? Because the savings hit your utility bills almost immediately.

- Plants often cut 10–25% of total energy use within the first year

- That’s $500K–$2M in annual savings for large energy users

- Which means you can recoup your investment in 12–24 months

- Add demand-response incentives or carbon credits, and payback can drop to just 6–9 months

Start with high-energy-load equipment like furnaces, compressors, and HVAC systems to show results fast.

CAPEX vs OPEX: Financing Your AI Project

Here’s the good news: you don’t have to buy it all upfront.

- CAPEX model: One-time investment, low ongoing costs. Great if you’ve got the capital and want long-term ownership.

- OPEX (subscription) model: Pay monthly or as a percentage of savings. Lower risk, easier budget approvals, and spreads the cost over time.

Some vendors even offer “shared savings” models – they only get paid when you save.

Bottom line: When you frame it with real numbers, AI-based energy optimization becomes less of a “green initiative” and more of a profit lever.

It’s not just about saving the planet – it’s about boosting margins and crushing energy costs.

The Road to 2030: Forecasts & Scenarios

When you look at where industrial energy efficiency is heading, one thing becomes clear: AI isn’t just a nice-to-have – it’s becoming the baseline. And by 2030, the gap between plants that embrace AI-driven energy optimization and those that don’t will look like night and day.

What the Forecasts Are Saying

Organizations like the International Energy Agency (IEA) and BloombergNEF (BNEF) have been blunt: industrial sectors must slash energy intensity by at least 3% per year through 2030 to stay aligned with global net-zero goals. That sounds small – until you compound it. A 3% annual improvement means plants could be using nearly 25% less energy per unit of output by 2030 compared to today.

And here’s the kicker: IEA modeling shows that over half of those gains will need to come from digital technologies, especially AI-driven energy management systems. This isn’t theoretical. We’re already seeing early adopters trim 15–30% off their energy bills within a couple of years.

BNEF adds another layer: if carbon pricing and stricter efficiency mandates accelerate, energy could become the #2 operating cost in many industries (right after raw materials). Companies that fail to improve energy performance will see their margins crushed – while AI leaders lock in ultra-low costs.

Tipping Points That Could Change the Game

The next five years could bring several tipping points:

- Energy price volatility: As renewables expand, prices will swing more during peak and off-peak. AI-powered load shifting will be the only way to survive those swings.

- Carbon regulations: The EU’s CBAM (Carbon Border Adjustment Mechanism) and similar policies could slap massive fees on energy-inefficient production.

- Customer pressure: Supply chain audits are going green. Big buyers are demanding energy and carbon transparency from their vendors – and they’ll favor plants that use AI to optimize energy.

Once these tipping points hit, the adoption curve for AI will go vertical. Plants that delay could spend years playing catch-up.

The Competitive Landscape in 2030

By 2030, expect AI energy optimization to be as standard as SCADA or ERP systems are today. Companies will compete not just on product quality or delivery time, but on energy cost per unit produced.

If you want your plant to still be competitive then, the math is simple: start the AI journey now, while the ROI curve is still steep. The early movers will be the ones setting the cost benchmarks everyone else struggles to hit.

Conclusion – Why AI Is Your Fastest Route to Lower Energy Costs

If there’s one thing this entire journey makes crystal clear, it’s this:

AI isn’t just optimizing energy use – it’s rewriting the rules of industrial cost structures.

Think about it. For decades, energy costs have been treated as a fixed burden – something you manage, not something you can radically shrink. But AI is flipping that mindset. Plants across sectors are proving that energy consumption can be turned from a runaway expense into a controllable, predictable, even strategic lever.

And the competitive gap is widening fast.

- While traditional plants wrestle with idle machines, energy-hungry HVAC systems, and human error,

- AI-driven plants are automatically fine-tuning every motor, fan, compressor, and boiler based on real-time data.

They’re forecasting energy demand, shifting loads to off-peak hours, and squeezing double-digit efficiency gains from assets that seemed “fully optimized” just a few years ago.

The result? Lower energy bills. Higher margins. Faster ROI.

This is no longer experimental – it’s proven. Companies are reporting 15–30% energy savings within the first 18–24 months of deploying AI-driven energy platforms. And as energy prices rise and carbon regulations tighten, that savings line will only get steeper.

How to Start (Pilot → Scale)

Here’s the simple playbook to get moving:

- Pick one pilot line or facility – preferably with high energy intensity and clear metering.

- Deploy AI-powered energy analytics with IoT sensors and real-time dashboards.

- Capture and publicize quick wins – even a 5–10% reduction builds momentum and trust.

- Scale in waves – extend to more systems (HVAC, boilers, chillers), then full plant-wide optimization.

- Train your ops teams to make data-driven energy decisions daily.

Don’t try to do it all at once – speed beats scope at the start. The key is to get visible savings fast, then reinvest them into scaling your AI efforts.

📣 Your Next Move

If you’re serious about lowering energy costs and staying competitive into the 2030s, waiting is not an option. Every month you delay is another month your competitors are widening their cost advantage.

👉 Start exploring real-world AI energy case studies today.

👉 Subscribe to stay ahead of the curve – because the companies that lead this shift won’t just save energy… they’ll own their markets.