- Introduction: The Shift to Smart Manufacturing

- What Is Predictive Quality Control (PQC)?

- How AI Enhances Predictive Quality Control

- Key Benefits of AI-Driven PQC in Manufacturing

- Real-World Case Studies: AI in Action

- Implementation Challenges and Solutions

- Future Trends in AI-Driven PQC

- How to Get Started: Tools, Platforms, and Strategy

- Final Thoughts: The Smart Path Forward

- FAQs on AI and Predictive Quality in Manufacturing

Introduction: The Shift to Smart Manufacturing

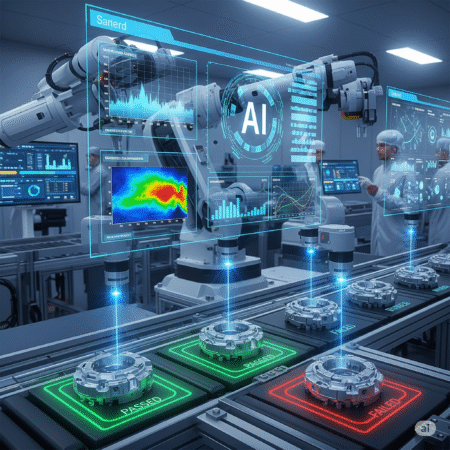

Manufacturing is evolving rapidly. Traditional quality control methods are no longer enough to stay competitive. With the rise of Industry 4.0, factories are turning to AI-driven predictive quality control (PQC) to stay ahead. Imagine identifying a defect before it causes production loss that’s the promise of predictive AI in manufacturing.

Key Insight: Manufacturers using AI in quality control reduce defects by up to 30% and increase efficiency by 25% (source: McKinsey).

What Is Predictive Quality Control (PQC)?

Predictive quality control is the proactive process of anticipating quality issues before they occur using data-driven insights. Instead of relying solely on after-the-fact inspections, PQC empowers manufacturers to:

Collect continuous quality data from machines, sensors, and production lines.

Analyze this data in real time to detect anomalies.

Take corrective action proactively.

Traditional QC vs. Predictive QC:

| Aspect | Traditional QC | Predictive QC |

|---|---|---|

| Timing | After production | During production (real-time) |

| Action | Reactive | Proactive |

| Technology | Manual, sampling-based | AI, Machine Learning, IoT |

How AI Enhances Predictive Quality Control

AI transforms PQC by providing:

Machine Learning Algorithms

AI learns from historical production data and identifies patterns associated with defects. Over time, these models become smarter and more accurate.

Computer Vision for Visual Inspection

AI-based cameras can detect micro-defects invisible to the human eye at scale and speed.

Anomaly Detection with Real-Time Data

AI can flag out-of-spec conditions as they occur, preventing faulty units from advancing down the line.

Integration with MES & SCADA

AI systems can be embedded into your Manufacturing Execution System (MES) and SCADA to act on insights autonomously.

Key Benefits of AI-Driven PQC in Manufacturing

Here’s why leading manufacturers are adopting AI-powered quality control:

Reduced Waste: AI can identify root causes of scrap and rework, saving material costs.

Faster Time-to-Detection: Real-time alerts reduce downtime.

Improved Accuracy: AI removes human subjectivity from inspections.

Lower Cost of Poor Quality (COPQ): Catching defects early lowers warranty claims and returns.

Sustainability Gains: Less waste means a greener production process.

Real-World Case Studies: AI in Action

Siemens

Integrated AI into its turbine blade factory. Result: 30% faster detection of welding defects.

Bosch

Uses predictive quality control with IoT sensors to monitor machine vibrations – reducing machine-related quality failures by 40%.

Unilever

Deployed real-time AI analytics across 300+ factories, improving output consistency and reducing batch variability.

These aren’t pilot projects. They’re full-scale implementations delivering results.

Implementation Challenges and Solutions

Adopting AI-based PQC comes with hurdles. Here’s how to address them:

| Challenge | Solution |

|---|---|

| Data Silos | Integrate data from MES, ERP, sensors via a data lake or unified platform |

| Skill Gaps | Upskill teams or partner with AI vendors |

| Cost Concerns | Start small (one line or plant) and scale based on ROI |

| Resistance to Change | Use internal champions and communicate early wins |

Pro Tip: Use platforms like AWS Lookout for Equipment, SparkCognition, or Sight Machine for faster implementation.

Future Trends in AI-Driven PQC

Edge AI: More analytics will run locally on machines, reducing latency.

Explainable AI (XAI): Operators will better understand AI decisions.

Closed-loop Control: AI not only detects but also corrects in real time.

Digital Twins: Simulate quality outcomes before production begins.

How to Get Started: Tools, Platforms, and Strategy

Step-by-step strategy:

Define a measurable quality KPI (e.g., defect rate, scrap percentage).

Identify the right pilot line – preferably high volume or high cost.

Collect clean, historical data for training your AI models.

Choose your tech stack: Cloud-based AI, edge sensors, or hybrid?

Launch and iterate – continuously feed new data to retrain AI.

Recommended Tools:

Google Cloud Vertex AI

IBM Maximo for Quality

Microsoft Azure AI for Manufacturing

Final Thoughts: The Smart Path Forward

AI-driven predictive quality control isn’t a futuristic concept – it’s here, it’s working, and it’s transforming factories across the globe. Manufacturers who adopt early will outperform those who don’t. It’s not just about technology – it’s about agility, precision, and staying competitive in the smart manufacturing era.

FAQs on AI and Predictive Quality in Manufacturing

Q1: Is predictive quality control only for large factories?

No. Small and mid-size factories can start with affordable AI platforms and scale as they grow.

Q2: What data is needed?

Sensor data, images, vibration data, machine logs – any data related to product quality.

Q3: How soon can ROI be seen?

Many manufacturers report ROI within 6 to 12 months after AI-PQC implementation.

Ready to boost your factory’s quality and output with AI?

Start implementing predictive quality control today.

👉 Subscribe to our newsletter for expert tips and tools weekly!