Introduction

In industries where failure isn’t an option – like oil & gas, power generation, or heavy manufacturing – Asset Integrity Management (AIM) plays a vital role. Yet, traditional methods for managing asset health are reactive, slow, and often expensive.

Enter Artificial Intelligence.

AI is revolutionizing asset integrity by enabling real-time monitoring, predictive analytics, and autonomous decision-making. The result? Reduced unplanned downtime, fewer safety incidents, and maximized equipment lifespan.

In this article, we’ll explore how AI-driven Asset Integrity Management is transforming industrial reliability, risk reduction, and operational efficiency.

What is Asset Integrity Management?

Asset Integrity Management (AIM) is the process of ensuring that industrial assets – such as pipelines, pressure vessels, rotating equipment, and structures – are designed, maintained, and operated in a way that ensures safety, reliability, and performance throughout their lifecycle.

Key elements of AIM include:

- Inspection planning

- Risk-based maintenance

- Failure analysis

- Regulatory compliance

- Documentation and traceability

AIM is critical because even minor failures can result in catastrophic safety incidents, environmental damage, or multi-million-dollar losses.

Traditional AIM relies heavily on manual inspections, static maintenance schedules, and historical data – methods that lack precision and responsiveness.

That’s where AI comes in.

The Role of AI in Asset Integrity

AI introduces predictive and adaptive intelligence into the AIM ecosystem. It enables industrial operators to:

- Detect early signs of degradation

- Predict failure before it happens

- Automate risk assessment

- Optimize inspection schedules

- Integrate real-time sensor data

Key AI components in AIM:

- Machine Learning (ML): Learns from asset history and sensor data to predict failures.

- Computer Vision: Inspects surfaces, welds, or corrosion via drone or robot imagery.

- Natural Language Processing (NLP): Parses inspection reports or maintenance logs for insight.

- Digital Twins: Create a virtual model of physical assets for real-time simulation and health monitoring.

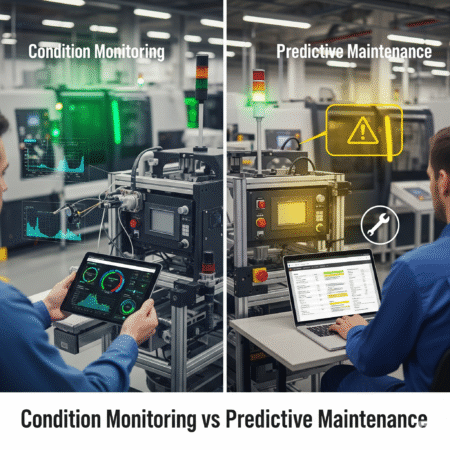

With AI, AIM shifts from calendar-based to condition-based strategies – making reliability smarter and faster.

AI Techniques for Risk Prediction and Anomaly Detection

Let’s break down how AI actually predicts problems before they cause damage:

Predictive Maintenance Models

Using supervised machine learning, AI algorithms analyze:

- Vibration patterns

- Temperature spikes

- Pressure deviations

- Fluid chemistry changes

Then it flags probable failure points before they escalate.

Anomaly Detection

Unsupervised learning models detect patterns that deviate from “normal” operations – flagging previously unknown failure modes.

Reinforcement Learning

Some systems learn optimal maintenance actions over time by “rewarding” successful strategies and minimizing failures.

Sensor Fusion

AI fuses data from multiple sensors (e.g. thermography, ultrasonic, acoustic) to improve prediction accuracy.

With AI, anomaly detection becomes proactive, not just reactive.

Case Studies: Real-World Applications

Shell – Offshore Oil Platforms

Shell deployed AI to monitor corrosion under insulation (CUI) on its offshore platforms. Using image recognition and predictive models, the company reduced inspection time by 50%.

GE Power – Gas Turbines

GE implemented digital twins of its gas turbines to simulate operating conditions. AI flagged mechanical issues 30 days before failure, saving millions in unplanned downtime.

Siemens – Industrial Motors

By integrating AI with SCADA and DCS data, Siemens detected anomalies in rotating machinery and cut maintenance costs by 25%.

These examples show how AI isn’t just theoretical – it’s delivering real ROI.

Benefits of AI-Driven Asset Integrity

Why industries are shifting to AI-based AIM:

✅ Reduced Downtime: Predict issues before they cause shutdowns.

✅ Enhanced Safety: Fewer human inspections in hazardous areas.

✅ Cost Savings: Optimize inspection intervals and resource allocation.

✅ Data-Driven Decisions: AI provides real-time, evidence-based insights.

✅ Extended Asset Life: Minimize over-stress and premature wear.

✅ Regulatory Compliance: Automate reporting and traceability.

Challenges and Considerations

AI adoption isn’t plug-and-play. Consider these roadblocks:

- Data Quality: Inaccurate or incomplete sensor data leads to poor AI performance.

- Integration Complexity: Bridging legacy systems with modern AI platforms is no small task.

- Cybersecurity Risks: AI requires connectivity – which must be protected.

- Skill Gaps: Organizations must upskill engineers in data science and AI.

To succeed, AI in AIM needs the right infrastructure, people, and processes.

Future Trends

AI in asset integrity is just getting started. Here’s what’s next:

- Autonomous Inspection Drones

- AI-powered Robotics for NDT (Non-Destructive Testing)

- Blockchain-integrated Asset Records

- Augmented Reality for On-site Maintenance

- Cross-plant AI Analytics (Fleet Learning)

The future is automated, connected, and intelligent – AI will be the backbone of next-gen reliability.

Conclusion

AI is reshaping the future of asset integrity management – transforming it from reactive maintenance to intelligent, predictive reliability. Companies that adopt AI not only reduce risk and cost, but also gain a competitive edge in asset performance and uptime.

Take the Next Step

Want to learn how AI can improve your industrial reliability and safety?

👉 Read our guide to AI in Predictive Maintenance

👉 Discover how Digital Twins revolutionize operational efficiency