- Introduction: The Digital Shift That Oil & Gas Can’t Ignore

- What Happens When AI Meets Digital Twin

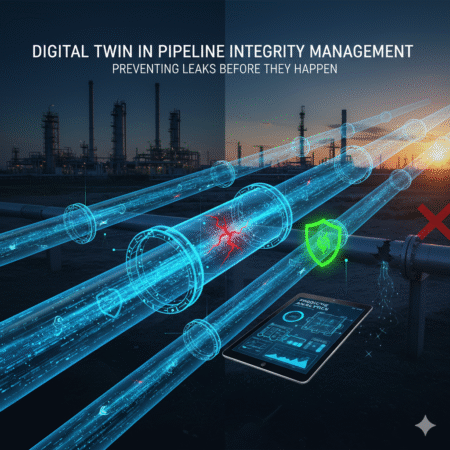

- Key Use Cases Transforming Oil & Gas Operations

- Technical Backbone: Data, IoT, and Edge AI

- Measurable ROI: Cost, Downtime, and Emissions

- Challenges & Barriers in AI-Digital Twin Adoption

- Case Studies: From Predictive to Autonomous Operations

- Future Outlook: 2025–2030 Roadmap to the Autonomous Oilfield

- Getting Started: Practical Steps for Integration

- Conclusion: The AI + Digital Twin Era Has Officially Begun

Introduction: The Digital Shift That Oil & Gas Can’t Ignore

In late 2024, a major offshore platform in the North Sea faced what could have been a $5 million disaster.

A single compressor anomaly-normally undetectable by traditional SCADA-was flagged three days earlier by an AI-powered digital twin. The maintenance crew fixed the issue before it triggered a full shutdown. No downtime. No spill. No headlines.

This isn’t sci-fi. It’s the new reality of oil & gas operations.

Every hour of unplanned downtime on an offshore platform can cost $1 million or more, according to industry reports by McKinsey and Deloitte. Multiply that across hundreds of wells, compressors, and pipelines, and the number becomes staggering. The sector bleeds billions annually due to preventable failures – corrosion, fatigue, and process upsets that could have been predicted.

Now, 2025 is shaping up to be a tipping point for digital transformation in oil & gas.

Aging assets, volatile prices, and ESG mandates are squeezing operators harder than ever. Meanwhile, AI models have matured. Edge computing is fast enough to run real-time analytics in the middle of the desert or offshore.

The convergence is clear: AI + Digital Twin = the brain and nervous system of the autonomous oilfield.

Forget static dashboards or periodic inspections – digital twins today simulate entire production systems, predict failures before they happen, and even recommend actions autonomously. Pair that with machine learning and generative AI, and you get what industry leaders call “self-optimizing assets.”

Companies like Shell, ADNOC, and Equinor are already proving the model works.

Shell’s predictive twin for rotating equipment cut unplanned downtime by 25%. ADNOC’s AI-integrated twins monitor 2,000+ assets in real time. Equinor’s digital twin platform helped shorten anomaly detection time by 30%.

So the question isn’t whether the oil & gas industry will embrace AI-driven twins – it’s who will do it fast enough to stay competitive.

The next sections will show exactly how this integration works, the ROI behind it, and how you can start building your own digital twin ecosystem – before your competitors do.

Infographic Concept (for this section):

“Why 2025 Is the Tipping Point for Oil & Gas Digitalization”

- Aging assets ↑

- Unplanned downtime costs ↑

- ESG & emission targets ↑

- AI maturity & edge computing power ↑

Convergence point: AI + Digital Twin Integration = Smarter, Safer, Autonomous Operations

What Happens When AI Meets Digital Twin

Imagine this – your refinery has a digital twin that perfectly mirrors every valve, pump, and compressor. It shows pressure drops, temperature spikes, and vibration patterns. But that’s just half the story. The real magic happens when AI becomes the brain behind the twin.

Think of it this way:

🧠 AI is the mind – it learns, predicts, and makes decisions.

🦾 The Digital Twin is the body – it senses, visualizes, and executes.

Read More: Digital Twin and AI Synergy in Plant Operations

When they work together, your operations go from reactive to autonomous.

In a traditional setup, engineers rely on SCADA or historians to see what’s happening now. But a digital twin powered by AI doesn’t just monitor – it understands. It identifies early warning signs, runs simulations in seconds, and even suggests what to do next.

For example, if pressure in a subsea pipeline begins to fluctuate, an AI-augmented twin doesn’t just raise an alarm – it analyzes historical flow data, correlates it with corrosion patterns, and predicts whether that fluctuation is a sign of a potential leak or just a sensor drift. That’s the kind of intelligence human teams can’t replicate manually at scale.

According to Gartner (2024), organizations integrating AI into digital twins see up to 30% improvement in asset reliability and 40% reduction in unplanned downtime within two years. That’s why industry giants like Equinor and ADNOC are merging AI analytics engines directly into their digital twin platforms – creating what’s now known as “Cognitive Twins.”

These systems can simulate thousands of “what-if” scenarios – like changing pump speeds, temperature variations, or chemical composition – to recommend the most efficient operational setup in real time.

It’s not just about automation; it’s about evolution.

We’re moving from:

Reactive Monitoring → Predictive Intelligence → Prescriptive Control → Fully Autonomous Operations.

In essence, AI gives the Digital Twin intuition – the ability to learn from data, adapt, and act before a problem happens.

The result? Fewer shutdowns, lower emissions, and smarter decisions – made by algorithms but validated by engineers.

Mini Infographic Concept:

“AI + Digital Twin = Human-Like Intelligence for Industrial Assets”

🧠 Sensors → 🌐 Digital Twin → 🤖 AI Analytics → ⚙️ Real-Time Decision → 🚀 Autonomous Operations

Key Use Cases Transforming Oil & Gas Operations

Imagine an offshore rig that can see problems before they happen. Pumps that predict failure days in advance. Pipelines that whisper early warnings about corrosion. Refineries that self-optimize fuel yield without human intervention.

That’s not sci-fi anymore – it’s what happens when AI meets the Digital Twin in oil & gas.

Upstream: Smarter Wells, Safer Drilling

In exploration and drilling, every second of downtime burns thousands of dollars. By combining real-time sensor data with AI-powered twins, companies like Equinor and Shell simulate thousands of “what-if” scenarios before making a drilling decision.

A predictive twin can model bit wear, mud weight, and formation pressure simultaneously – helping operators prevent stuck pipes or blowouts.

Result? Faster wells, fewer surprises, and up to 25% reduction in non-productive time (NPT).

Midstream: Predicting Leaks Before They Happen

Pipelines are the arteries of the industry – and leaks are catastrophic both financially and environmentally.

AI-driven twins monitor flow, vibration, and pressure patterns across the entire network. Machine learning models spot anomalies invisible to human eyes – such as micro-vibrations that precede a leak.

In one pilot, a US midstream operator using an AI twin cut unplanned shutdowns by 40% within six months.

Downstream: The Self-Optimizing Refinery

In refineries, even a 1% efficiency gain can mean millions in savings.

Digital twins map entire process units – from distillation columns to compressors – in real time. When combined with AI, they become living systems that continuously optimize temperature, pressure, and catalyst feed.

BP’s refinery in Rotterdam reported up to 15% improvement in yield after deploying an AI-enabled twin trained on historical process data.

Mini Case Study: Equinor + Cognite Data Fusion

Equinor integrated thousands of sensors into its offshore digital twin using the Cognite Data Fusion platform. With AI anomaly detection, it identified equipment degradation 30% faster than traditional monitoring. The system didn’t just alert engineers – it explained why an anomaly was happening, enabling prescriptive action instead of reactive maintenance.

Bottom line:

From the seabed to the refinery stack, AI-powered digital twins aren’t just “nice to have” – they’re rewriting how oil & gas assets operate. Each twin becomes smarter over time, turning reactive maintenance into predictive insight and, ultimately, autonomous performance.

Technical Backbone: Data, IoT, and Edge AI

If AI and Digital Twins are the brain and body of the modern oilfield, data is the lifeblood.

Without fast, clean, and connected data – your twin is just a fancy 3D model collecting digital dust.

From Sensors to Situational Awareness

Every compressor vibration, pipeline pressure pulse, and temperature fluctuation tells a story.

IoT sensors capture these micro-signals 24/7 – and when connected through an integrated network, they feed a real-time mirror of your operations.

In one offshore field operated by Petronas, over 100,000 data points per second flow from sensors into their digital twin, allowing engineers to visualize flow efficiency and asset health instantly.

But raw data alone is noise. The real magic happens when AI interprets the data and learns from it – detecting patterns that humans would miss.

Why Edge AI is a Game Changer

Traditional analytics depend on the cloud. But offshore rigs or remote pipelines don’t always have stable connectivity.

That’s where Edge AI steps in – bringing intelligence closer to the source.

Instead of sending terabytes of data to the cloud, edge devices process analytics on-site in milliseconds.

Think of it as giving every pump or valve its own mini brain.

For example, a pipeline twin powered by edge AI can identify a pressure anomaly and trigger an automated valve shutdown – before data even leaves the facility.

Result: latency drops by up to 80%, and risk of environmental leaks shrinks dramatically.

Cloud vs Edge vs Hybrid: Finding the Right Balance

The future isn’t either-or – it’s hybrid.

- Cloud: perfect for large-scale data storage, AI training, and visualization dashboards.

- Edge: ideal for real-time control, safety-critical decisions, and low-latency tasks.

- Hybrid: best of both – where AI models are trained in the cloud, deployed at the edge, and continuously refined through feedback loops.

Real-Time Visualization: The Command Center

All this tech converges in the control room – a living dashboard showing asset performance, energy use, and predictive alerts in one unified interface.

Operators no longer wait for reports. They see the health of their field, in real time, across thousands of assets.

Bottom line:

The integration of IoT sensors, edge intelligence, and hybrid cloud is what turns digital twins from static replicas into living, thinking systems.

It’s not just data – it’s decisions in motion.

Measurable ROI: Cost, Downtime, and Emissions

Let’s get real – no technology survives in oil & gas unless it proves financial value.

AI-powered digital twins are not just cool dashboards or flashy 3D models. They save millions in downtime, cut emissions, and boost reliability in ways spreadsheets alone can’t show.

Downtime: Every Minute Costs Millions

In offshore operations, downtime can cost anywhere between $300,000 to $1 million per hour.

That’s not a typo – one failed compressor or unplanned shutdown can drain your OPEX faster than any equipment purchase ever could.

Here’s the twist: companies like BP and Shell report up to 40% reduction in unplanned downtime after deploying predictive digital twins.

By analyzing live sensor data and learning behavioral patterns, the AI twin can detect a failing valve or compressor days before it happens – triggering a planned intervention instead of an emergency shutdown.

Cost Efficiency: From Reactive to Predictive to Autonomous

When you move from manual maintenance to predictive operations, the savings snowball.

AI twins optimize not just when maintenance happens, but why and how.

Take TotalEnergies, which implemented a hybrid AI twin for refinery assets – resulting in a 22% cut in OPEX and 30% faster root-cause diagnosis across its European sites.

Here’s a quick comparison snapshot:

| Approach | Unplanned Downtime | Maintenance Cost | Operator Involvement | ROI Timeline |

|---|---|---|---|---|

| Manual (Reactive) | Very High | High | Continuous | >3 years |

| Predictive (AI-Assisted) | Moderate | Medium | Partial Automation | 12–18 months |

| Autonomous (AI Twin) | Low | Low | Minimal | 6–12 months |

ESG and Emission Benefits

In 2025, ESG isn’t just a buzzword – it’s a business driver.

AI-driven twins help optimize pump speeds, burner efficiency, and process heat balance – reducing CO₂ emissions by 8–15% per site on average.

For a 200,000-barrel-per-day refinery, that’s equivalent to taking 30,000 cars off the road annually.

The ROI Multiplier

When you integrate AI-driven decision loops across multiple assets, the ROI compounds.

Petronas Digital Twin 360 project, for instance, reported 25% reduction in OPEX and a 2× improvement in asset reliability index.

That’s not theory – that’s transformation at scale.

Bottom line:

Every dollar invested in AI-driven digital twins returns $3–$5 in measurable savings within the first two years – through reduced downtime, optimized energy use, and smarter operations.

And in an era where margins are razor-thin and ESG compliance is mandatory, that’s the kind of ROI story executives actually listen to.

Challenges & Barriers in AI-Digital Twin Adoption

Let’s face it – the road to AI-driven digital twins isn’t smooth.

While headlines talk about “autonomous oilfields” and “self-optimizing refineries,” the truth on the ground is far more complex.

Behind every success story from Shell or ADNOC, there are years of trial, integration headaches, cybersecurity scares, and cultural resistance.

So, what’s holding the rest of the industry back?

Data Silos: The Invisible Wall

Imagine having thousands of sensors – vibration, flow, corrosion, temperature – all streaming data 24/7… but stored in five different systems that don’t talk to each other.

That’s the reality in most facilities. SCADA, CMMS, ERP, and historian systems operate like rival kingdoms.

According to a 2024 Deloitte report, 65% of digital twin projects fail to scale because of fragmented data architecture.

Until those silos break, AI models are flying blind.

How to fix it:

Adopt a “data lakehouse” or unified OT/IT architecture that merges real-time sensor data with maintenance history and enterprise data – enabling one truth for all systems.

Cybersecurity: When Your Twin Gets Hacked

The more connected your twin, the more exposed your assets.

In 2023, a major pipeline operator in North America had to shut down its digital twin network after a malware infiltration via an IoT gateway.

Lesson learned? Connectivity without security is a ticking time bomb.

Solution:

Apply a “zero trust” model – continuous authentication, encrypted OT/IT bridges, and AI-driven anomaly detection to monitor suspicious data flows.

Skill Gap: AI Meets Old-School Operations

Many engineers grew up mastering P&IDs, not Python.

The shift from manual maintenance to AI-driven decision-making requires upskilling entire teams, not just hiring a few data scientists.

McKinsey’s 2024 Energy Report found that over 70% of digital transformation delays in oil & gas were caused by workforce capability gaps, not technology itself.

Fix:

Start hybrid training – mix traditional reliability engineering with AI model interpretation, and empower control room staff to trust (and challenge) the twin’s insights.

CAPEX & Infrastructure Limitations

Building a full-scale digital twin ecosystem costs millions upfront – sensors, servers, edge devices, integration software.

That’s a hard sell when oil prices fluctuate or when management demands immediate payback.

But skipping foundational investment leads to partial twins that never deliver ROI.

Tip:

Start small – one asset, one pilot. Scale only when ROI is visible and measurable.

The Human Factor: Resistance to Change

Finally, the toughest barrier isn’t technical – it’s cultural.

Field engineers who’ve relied on intuition for decades can be skeptical of an algorithm telling them what to do.

Until leadership reframes AI and digital twin as decision-support tools (not job replacements), adoption will stall.

Mini Infographic Concept

“Top 5 Barriers vs How to Overcome Them”

| Barrier | Impact | Solution |

|---|---|---|

| Data Silos | Low model accuracy | Unified OT/IT data lake |

| Cyber Risk | System downtime | Zero Trust + encrypted gateways |

| Skill Gap | Low adoption | Hybrid AI–engineering training |

| CAPEX Limits | Pilot failure | Start small, scale smart |

| Cultural Resistance | Slow change | Leadership-driven buy-in |

Takeaway:

The companies that embrace these barriers head-on – not avoid them – are the ones who’ll own the next decade of oil & gas digitalization.

In other words, the real twin challenge isn’t tech… it’s transformation.

Case Studies: From Predictive to Autonomous Operations

Imagine this: an offshore platform in the Arabian Gulf, where a single compressor failure can cost $2 million in lost production per day. Just a few years ago, operators relied on manual inspections and reactive maintenance. Today, that same compressor runs under the watchful eye of an AI-powered digital twin – predicting failures before they happen.

This isn’t sci-fi. It’s real, and it’s happening right now.

Shell: From Monitoring to Predicting

Shell began its digital twin journey by modeling rotating equipment-turbines, compressors, and pumps. Using AI-driven anomaly detection, the system identifies deviations in vibration and pressure signatures days before alarms trigger.

Result? 43% reduction in unplanned downtime and a measurable improvement in asset availability.

What used to require on-site troubleshooting now happens in a digital control room with simulation-based decision-making.

ADNOC & Saudi Aramco: The Fully Connected Asset

ADNOC and Aramco have gone one step further. They’re not just monitoring equipment – they’ve built entire digital replicas of oilfields, from wellheads to processing plants. These “mega twins” integrate SCADA, CMMS, and AI analytics to enable predictive and prescriptive actions.

Aramco’s “Smart Operations Center” now leverages over 5 million data points per day, allowing AI agents to optimize production, predict corrosion, and even recommend valve adjustments autonomously.

It’s the foundation of the “self-learning” oilfield.

BP: Refinery Optimization with Generative AI

BP is taking digital twins to the next level – pairing them with generative AI models that simulate process variations in real time. When feedstock quality changes, the AI twin instantly runs optimization scenarios to maintain yield and reduce emissions.

This approach boosted BP’s refinery efficiency by 12%, while cutting CO₂ output by thousands of tons annually.

Insight:

Across all these leaders, one trend stands out – companies that move beyond pilot stage into full-scale AI-digital twin integration are achieving up to 2× ROI within three years.

Mini Infographic Concept:

“Pipeline to Autonomy” → Predictive → Prescriptive → Autonomous.

It’s not about replacing people – it’s about empowering engineers with a digital ally that never sleeps.

Future Outlook: 2025–2030 Roadmap to the Autonomous Oilfield

Picture this: it’s 2030. A single engineer sits in a remote command center in Abu Dhabi, overseeing multiple offshore platforms in real time. Pumps, compressors, valves, and even drilling systems adjust themselves based on changing flow dynamics – without human intervention. Downtime is nearly zero, energy waste is minimal, and safety incidents are almost nonexistent.

That’s not a fantasy – it’s the autonomous oilfield, powered by AI-integrated digital twins. And the journey to get there starts today.

Phase 1 (2025–2026): Data-Driven Predictive Maintenance

Most companies are here right now. They’re using sensor data, AI analytics, and digital twins to predict failures before they happen.

In this phase, the focus is on reducing OPEX and building trust in the digital ecosystem.

💡 Goal: Turn maintenance from reactive to predictive.

🔧 Example: Using AI twins to forecast compressor seal degradation or pipeline corrosion rates with 90% accuracy.

Phase 2 (2027–2028): AI-Powered Prescriptive Analytics

Once predictive models are mature, AI begins to recommend specific actions – not just highlight risks.

The system can simulate multiple “what-if” scenarios and suggest the most efficient response.

Think of it as a digital advisor that says,

“If you reduce pressure by 8% for the next 6 hours, you’ll prevent a $500K loss.”

💡 Goal: Optimize performance, not just prevent failure.

🌍 Result: Smarter, leaner, and greener operations aligned with ESG targets.

Phase 3 (2029–2030): The Self-Learning Autonomous Operation

By this stage, the digital twin evolves into an AI twin – capable of learning from every event, refining its models autonomously, and making real-time operational decisions.

This is where human oversight shifts to exception management, not control.

🧠 Goal: Full autonomy with human-in-the-loop governance.

⚙️ Result: Continuous optimization, zero unplanned downtime, and up to 30% OPEX reduction across the asset lifecycle.

Mini Infographic Concept

“Evolution Timeline: Digital Twin → AI Twin → Autonomous Oilfield”

- 2025: Predictive Maintenance → Early ROI (Reactive → Predictive)

- 2027: Prescriptive Optimization → Efficiency & ESG Alignment

- 2030: Autonomous Operations → Self-Learning Digital Ecosystem

The takeaway? The race to the autonomous oilfield has already begun. Companies that move early – investing in AI-digital twin integration today – will dominate the next decade of oil & gas efficiency, safety, and sustainability.

Getting Started: Practical Steps for Integration

If there’s one thing oil & gas companies have learned from digital transformation – it’s this: starting small beats waiting big. The shift toward AI-driven digital twins doesn’t happen overnight. It’s not about buying the most expensive software; it’s about building digital confidence step-by-step.

Let’s break down what a realistic, high-ROI roadmap looks like.

Step 1: Identify the Right Pilot Asset

Don’t start with your most complex platform. Start with a single compressor, pump, or separator – something with measurable downtime cost and high maintenance frequency.

📊 Pro tip: Choose equipment that already has rich sensor data – it makes AI training smoother.

Example: ADNOC’s pilot twin on a gas compressor reduced unplanned trips by 18% within six months.

Step 2: Assess Data Readiness

Garbage in, garbage out.

Before you even build a digital twin, assess how clean, structured, and accessible your data is. Most failures come from poor integration between SCADA, CMMS, and historian systems.

🧩 Checklist: completeness, timestamp accuracy, unit consistency, and sensor calibration.

When Equinor standardized its data models, analytics speed improved 5× even before full AI integration.

Step 3: Build & Validate a Small-Scale Digital Twin

Now, create a pilot twin focused on one measurable KPI – e.g., vibration prediction or energy efficiency.

Feed real-time data into the model and compare predictions versus actual events.

🧠 Goal: Build trust between field engineers and AI recommendations.

💡 Tip: Keep the twin transparent – engineers must understand why the AI makes certain predictions.

Step 4: Integrate with SCADA & CMMS

This is where your twin stops being “just a model” and becomes an operational tool.

Integrate alerts, maintenance recommendations, and performance KPIs directly into your control system dashboards.

🔗 Result: One unified view for operators – no more tab-switching between multiple tools.

Step 5: Scale Up to a Multi-Asset Twin Ecosystem

Once the pilot proves its ROI, replicate across similar assets – then connect them.

This ecosystem-level integration creates a digital nervous system that spans facilities, pipelines, and refineries.

🌐 Goal: Transition from isolated twins → enterprise digital twin network.

💰 ROI Insight: Companies that scale their twins typically achieve 2.3× faster payback than those stuck in pilot mode.

Checklist: Dos & Don’ts

✅ Start small, measure everything, celebrate early wins.

✅ Standardize data governance early.

❌ Don’t chase “perfect” data before starting.

❌ Don’t buy tech you can’t operationalize in 6 months.

Mini Infographic Concept

“Pipeline Digital Twin Roadmap: Pilot → Scale → Enterprise Adoption”

| Stage | Focus | Key Outcome |

|---|---|---|

| Pilot (6–12 mo) | Single asset twin | Early ROI & operator trust |

| Scale (1–2 yr) | Multi-asset twins | Cross-facility optimization |

| Enterprise (3–5 yr) | Connected AI twins | Autonomous operations |

The future autonomous oilfield won’t be built in a lab – it’ll be built through pilots that scale with proof.

Start with one compressor today, and by 2030, you could be managing a self-optimizing oilfield from your control center.

Conclusion: The AI + Digital Twin Era Has Officially Begun

Let’s face it — the oil & gas industry is standing at a historic crossroads. For decades, we’ve relied on periodic maintenance schedules, manual inspections, and reactionary decisions. But in 2025 and beyond, that model simply won’t cut it anymore.

When you combine AI’s predictive intelligence with Digital Twin’s real-time mirroring, you don’t just get visibility – you get foresight.

You don’t just monitor – you control, predict, and prevent.

Companies like Shell, ADNOC, and Equinor are already proving what’s possible:

→ 30% faster anomaly detection.

→ 25% reduction in unplanned downtime.

→ Millions saved per year in OPEX.

But here’s the kicker: the real value isn’t just in saving costs.

It’s in reshaping how the oilfield thinks and learns. Every sensor, every twin, every algorithm becomes part of a self-learning ecosystem that gets smarter every single day. That’s the foundation of autonomous operations – and it’s happening now.

So, if your organization hasn’t started its AI + Digital Twin journey, the best time was yesterday. The second-best time? Today.

Quick FAQ

Q1. How long does it take to see ROI from digital twin integration?

Most companies report measurable ROI within 12–18 months, especially when starting with high-impact assets like compressors, pumps, and pipelines.

Q2. What’s the biggest challenge for first-time adopters?

Data readiness. Without clean, connected, and contextualized data, even the most advanced AI won’t perform well.

Q3. Cloud or Edge – which is better?

Hybrid wins. Edge ensures low latency and faster insights, while cloud offers scalability and AI training capabilities.

Q4. Is AI-based automation safe for critical operations?

Yes – if governed by strict OT/IT cybersecurity frameworks and redundancy protocols. Many operators already run dual-safety validation layers.

CTA: Ready to Lead the Next Generation of Operations?

If your goal is to cut downtime, boost asset reliability, and future-proof your operations, now’s your moment.

Don’t just follow the digital wave – build it.

👉 Subscribe to EngineerDaily for deep dives into industrial AI, digital transformation, and future-ready energy systems.

Every article we publish gives you real-world frameworks, case studies, and data-backed insights to keep your operations ahead of the curve.

Infographic Concept:

“The AI x Digital Twin Impact Pyramid”

- Level 1: Cost Reduction

- Level 2: Safety & Compliance

- Level 3: Operational Efficiency

- Level 4: ESG & Sustainability

- Level 5: Autonomous Advantage