- Introduction: Why Edge AI is the Next Industrial Game-Changer

- What is Edge AI in Industrial Context?

- Why Industries Are Moving to the Edge

- Top Use Cases of Edge AI in Industrial Automation

- How Edge AI Integrates with Existing Industrial Systems

- Common Challenges and How to Overcome Them

- The Future of Edge AI in Industrial Automation

- Final Thoughts

Introduction: Why Edge AI is the Next Industrial Game-Changer

In the world of industrial automation, timing is everything.

A fraction of a second delay in decision-making can cost thousands sometimes even lives. Traditional cloud-based AI solutions, while powerful, struggle with latency, bandwidth limitations, and real-time responsiveness. This is where Edge AI comes in bringing artificial intelligence closer to the source of data, right at the edge of industrial systems.

The Shift Towards Decentralization

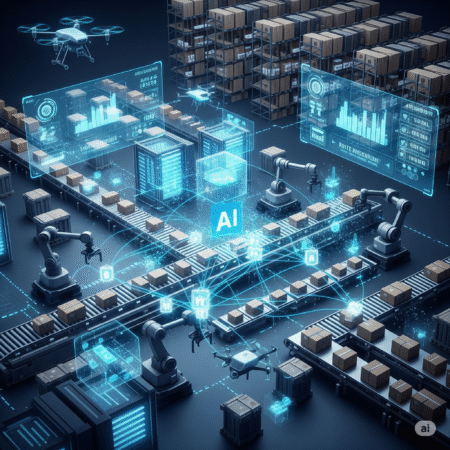

Industry 4.0 is all about smart, connected, and autonomous operations. But to truly achieve this vision, we can’t rely on sending data back and forth to centralized cloud servers. The demand is growing for instantaneous insights decisions that happen on-site, in real-time, without delay. That’s why Edge AI is no longer a buzzword. It’s the next industrial evolution.

What is Edge AI in Industrial Context?

Let’s make this simple.

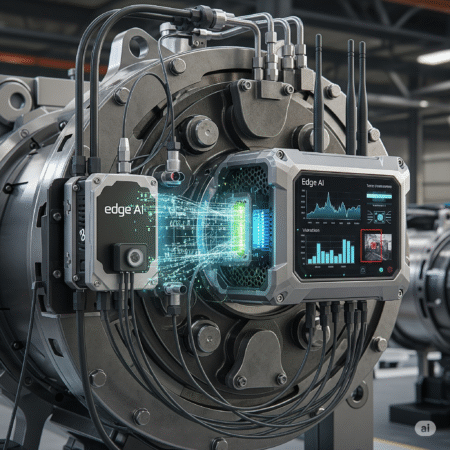

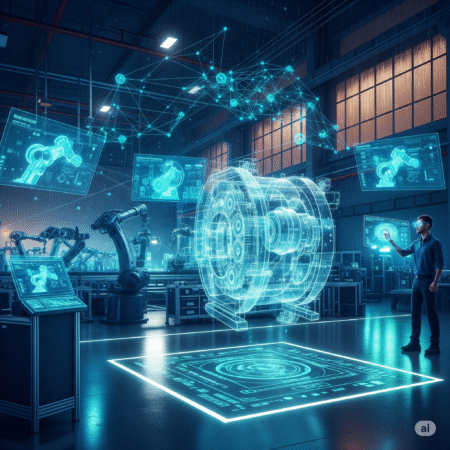

Edge AI refers to running artificial intelligence algorithms locally on devices like sensors, gateways, PLCs, or embedded systems—right where the data is generated. There’s no need to send it to the cloud for processing.

Real-World Example

Imagine a CNC machine with a vision camera doing quality inspection. Instead of uploading the image to a cloud server for analysis, the AI model runs locally on the camera itself – flagging defects in milliseconds. That’s Edge AI in action.

Key Differences from Cloud AI

| Feature | Edge AI | Cloud AI |

|---|---|---|

| Latency | Near zero | High (due to transmission) |

| Internet Dependency | Low or none | High |

| Data Privacy | Higher (local processing) | Riskier (central storage) |

| Cost | Lower bandwidth & infra cost | Higher transmission/storage |

Why Industries Are Moving to the Edge

Let’s break it down.

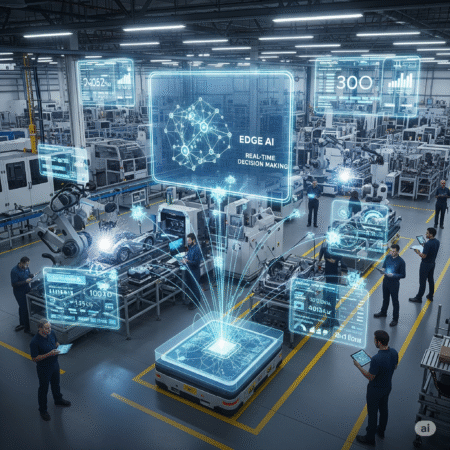

Real-Time Decision-Making

With zero-latency, Edge AI enables machines to make decisions on-the-fly. No delays. No bottlenecks. This is critical in safety systems, robotics, predictive maintenance, and more.

Reduced Bandwidth and Operational Cost

Instead of transmitting terabytes of data to the cloud, only actionable insights or anomalies are sent – cutting down network congestion and lowering OPEX.

Data Sovereignty & Security

In industries like oil & gas, energy, or pharmaceuticals, data privacy is everything. Keeping sensitive data on-premise helps meet regulatory compliance without risking leaks through cloud APIs.

Top Use Cases of Edge AI in Industrial Automation

Let’s talk practical applications – no fluff.

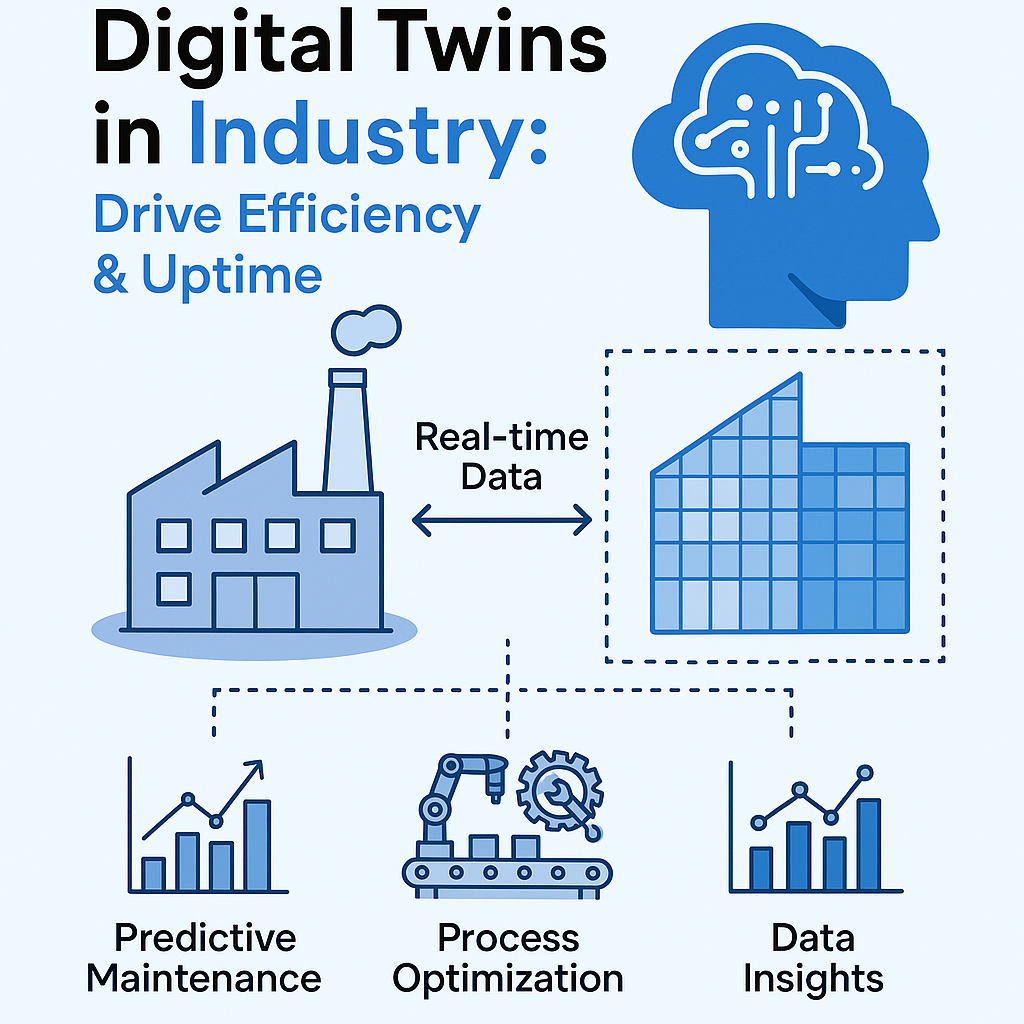

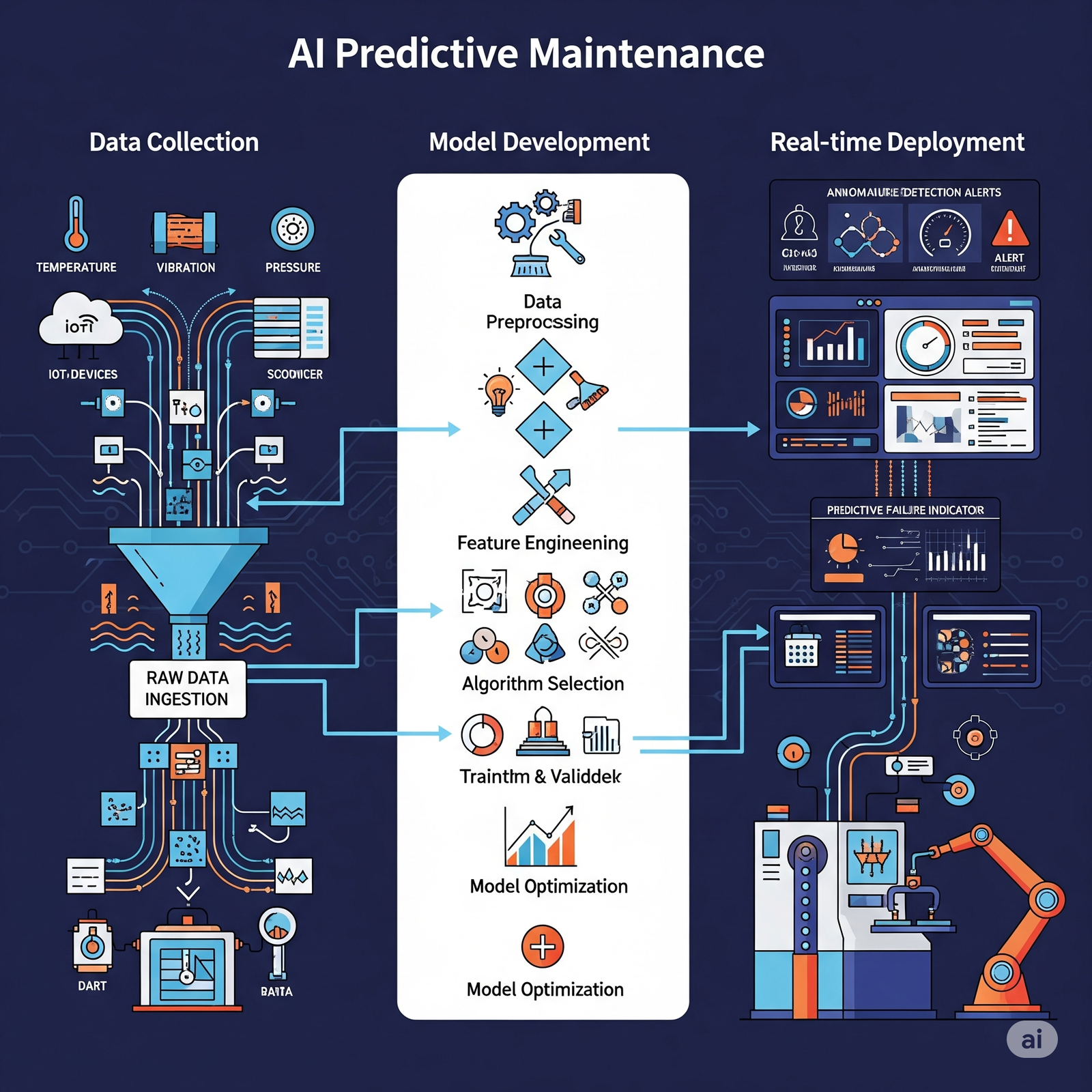

Predictive Maintenance

AI models running on edge devices can monitor vibration, temperature, acoustic signals, and more to predict equipment failure before it happens. This minimizes unplanned downtime and extends asset life.

Example: A motor with an edge-based AI model detects abnormal bearing vibration and schedules maintenance before a breakdown occurs.

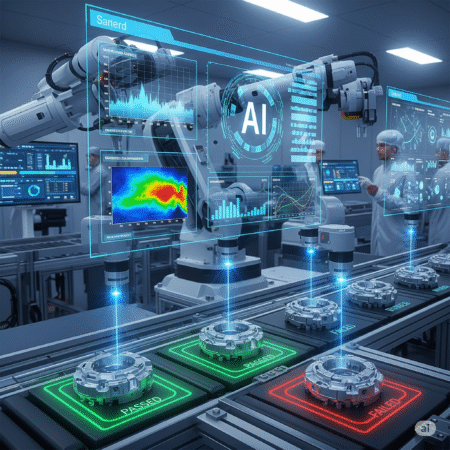

Visual Quality Inspection

Cameras equipped with Edge AI can inspect products in real-time, rejecting faulty items without slowing down the production line.

Example: Food packaging lines, where edge devices detect contamination or incorrect labels instantly.

Safety and Hazard Detection

Edge AI enables instant detection of hazardous gas leaks, smoke, fire, or intrusions using smart sensors. It can trigger alarms and shut down systems without waiting for cloud commands.

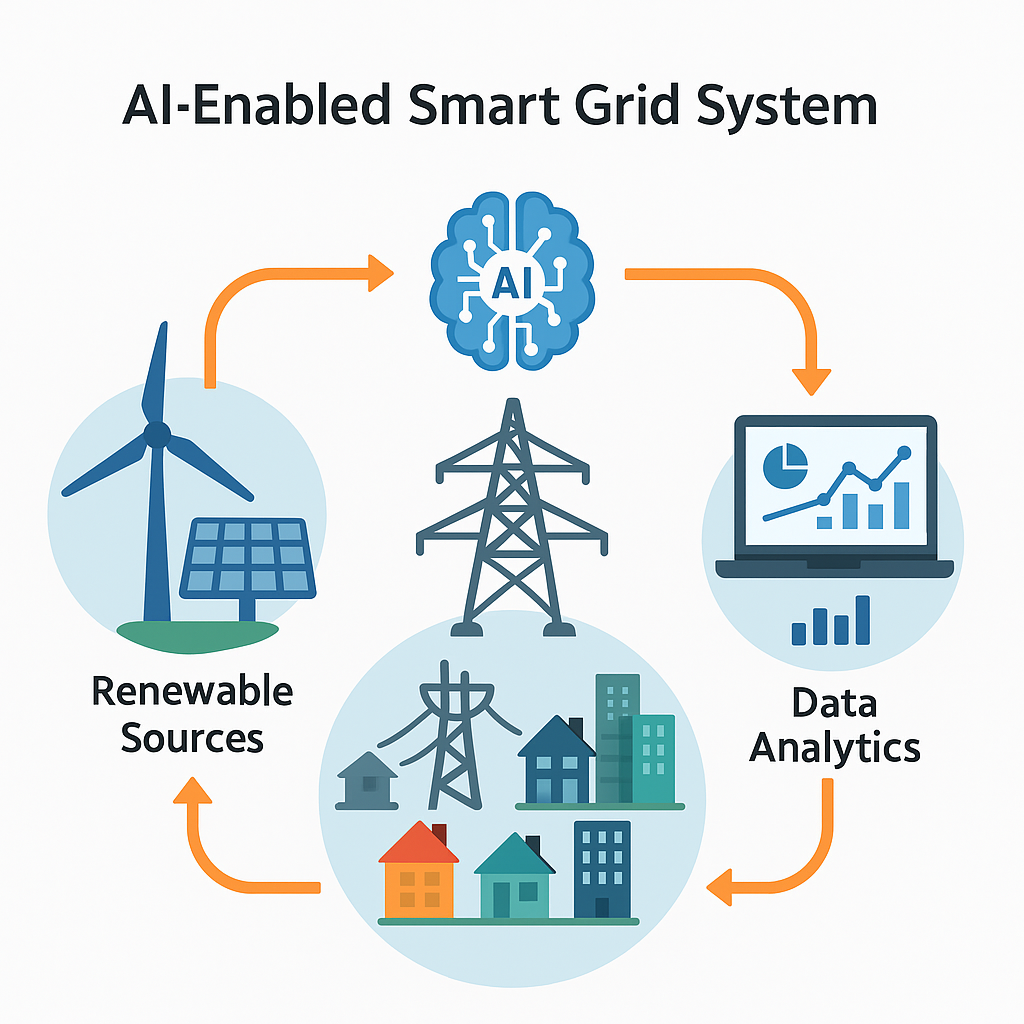

Energy Optimization

Edge AI optimizes HVAC, lighting, and machinery usage based on real-time occupancy and environmental data – saving costs and reducing emissions.

How Edge AI Integrates with Existing Industrial Systems

You don’t need to start from scratch.

Edge AI platforms are now designed to integrate seamlessly with legacy PLCs, SCADA, DCS, and MES systems. Here’s how:

- Edge Gateways: Act as bridges between sensors and enterprise systems.

- Industrial Protocol Support: Edge AI platforms support Modbus, OPC-UA, Ethernet/IP, etc.

- No-Code Interfaces: Some platforms allow engineers to train, deploy, and update AI models without writing a single line of code.

Common Challenges and How to Overcome Them

Nothing’s perfect. Edge AI brings its own set of challenges – but they’re solvable.

Hardware Limitations

- Problem: Edge devices often have limited computing power.

- Solution: Use optimized, compressed AI models (like TinyML or quantized CNNs) that run efficiently even on microcontrollers.

Model Updates and Management

- Problem: How do you update AI models deployed on hundreds of devices?

- Solution: Use AI model orchestration platforms that allow remote updates, version control, and A/B testing at the edge.

Data Labeling and Model Training

- Problem: Edge AI models still need labeled data.

- Solution: Use semi-supervised learning or leverage cloud-to-edge workflows where training happens in the cloud, and inference runs on the edge.

The Future of Edge AI in Industrial Automation

We’re just scratching the surface.

Edge AI is evolving rapidly with the rise of 5G, AI chips (like NVIDIA Jetson, Intel Movidius), and containerized deployments (e.g., using Docker or Kubernetes at the edge). In the next 3–5 years, expect to see:

- Self-learning machines

- Fully autonomous factories

- Zero downtime environments

- Decentralized, scalable AI ecosystems

Final Thoughts

Edge AI is no longer optional. It’s essential.

In a world where milliseconds matter, the ability to make decisions right at the source is the competitive edge industries can’t afford to ignore.

So if you’re in industrial automation and you’re still relying purely on cloud processing – it’s time to rethink your strategy.

Edge AI isn’t the future. It’s the now.