- Introduction: The Rise of Smart Monitoring in Industry

- What is Industrial Predictive Analytics?

- Why Use AI in Industrial Analytics?

- Top Use Cases in the Industrial Sector

- Step-by-Step: How to Implement Predictive Analytics with AI

- Key Metrics to Monitor

- Real-World Example: Predictive Maintenance in a Steel Plant

- Challenges & Solutions

- Future Outlook: What’s Next for AI in IIoT?

- Conclusion: Start Small, Scale Fast

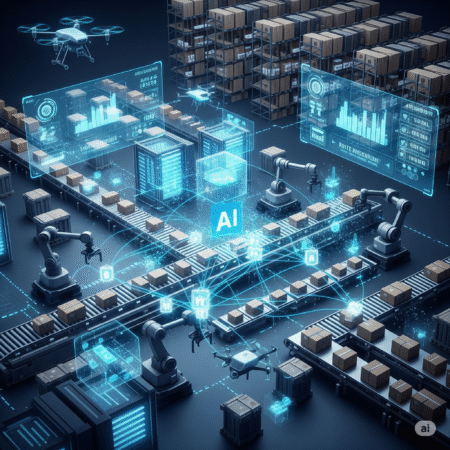

Introduction: The Rise of Smart Monitoring in Industry

The industrial landscape is evolving rapidly, driven by the need for efficiency, safety, and cost optimization. Traditional maintenance strategies like reactive and preventive maintenance are no longer enough. Enter AI-powered predictive analytics a game-changing approach that allows organizations to detect equipment issues before they become costly problems.

This article dives deep into how artificial intelligence (AI) and Industrial Internet of Things (IIoT) work together to deliver predictive maintenance at scale, providing you with a comprehensive, actionable guide.

What is Industrial Predictive Analytics?

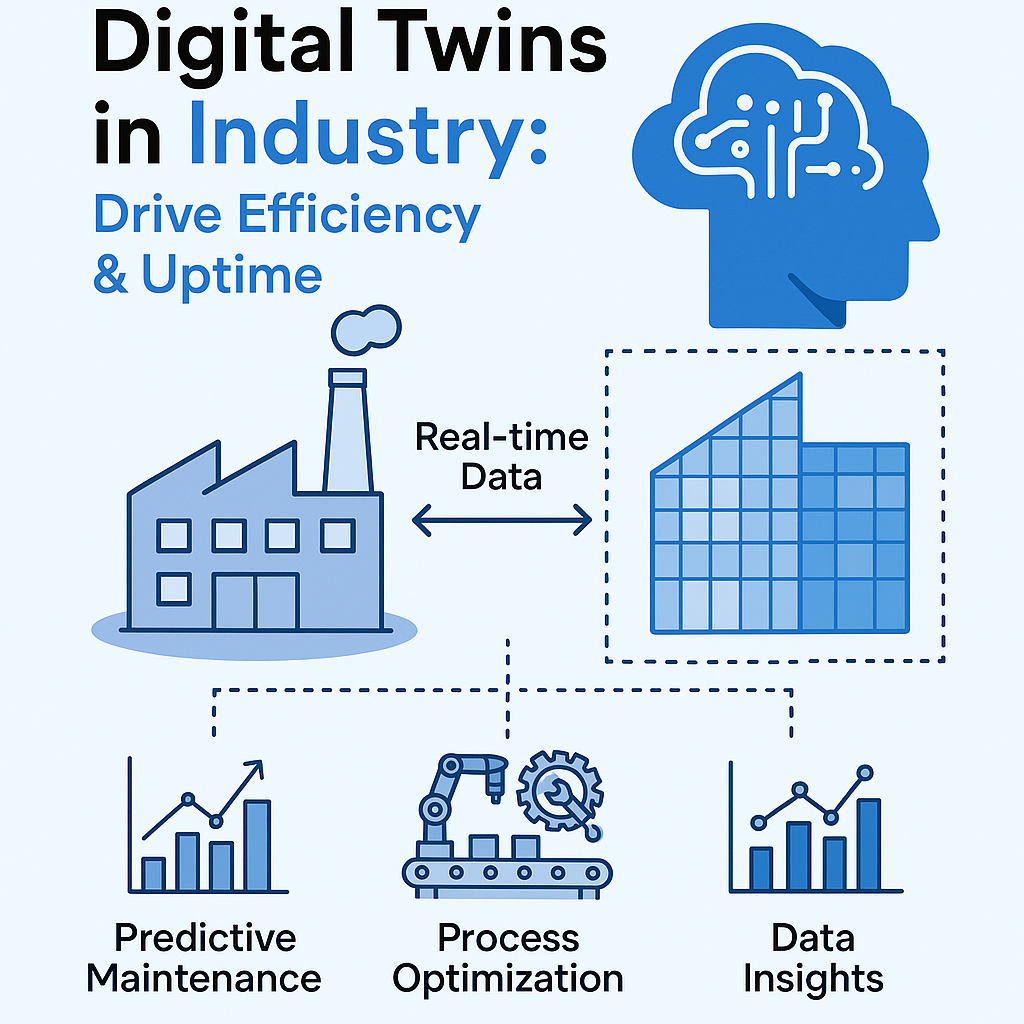

Predictive analytics in the industrial sector uses statistical algorithms, machine learning models, and data mining techniques to analyze current and historical data to predict future events. In the context of industrial IoT, predictive analytics helps monitor the health of machinery, identify patterns, and forecast failures.

Key Components:

- Sensors & IoT Devices: Gather real-time operational data (vibration, temperature, RPM, etc.)

- Data Processing Layer: Cleans and aggregates the data

- AI/ML Models: Analyze the data to detect anomalies and forecast failures

- Visualization Dashboards: Provide insights to engineers and decision-makers

Why Use AI in Industrial Analytics?

Early Fault Detection

AI models can detect minute deviations in equipment behavior, offering early alerts that human operators may miss.

Reduced Downtime

By predicting failures before they occur, maintenance can be scheduled proactively, minimizing unexpected downtime.

Cost Savings

Reduces the need for unnecessary preventive maintenance and lowers repair costs by catching issues early.

Enhanced Asset Life

Predictive analytics ensures machines run within optimal parameters, extending equipment lifespan.

Top Use Cases in the Industrial Sector

Induction Motor Monitoring

AI algorithms analyze vibration and current signature data to detect imbalances, misalignments, or bearing wear in motors.

Rotating Equipment Health

Real-time sensor data from pumps, turbines, and compressors is analyzed to forecast seal or blade failures.

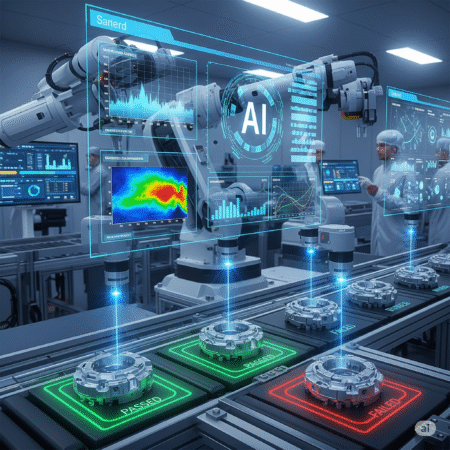

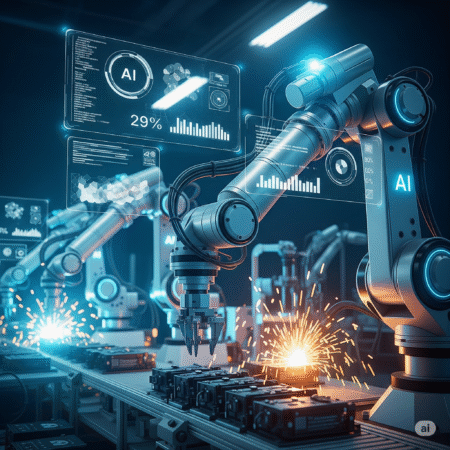

Manufacturing Assembly Line

Image-based AI detects defects in products or identifies bottlenecks in production lines.

Oil & Gas Pipelines

AI-powered monitoring detects pressure drops and corrosion, preventing leaks or catastrophic failures.

HVAC Systems in Industrial Plants

Predictive models monitor temperature trends, airflow, and energy consumption to detect anomalies.

Step-by-Step: How to Implement Predictive Analytics with AI

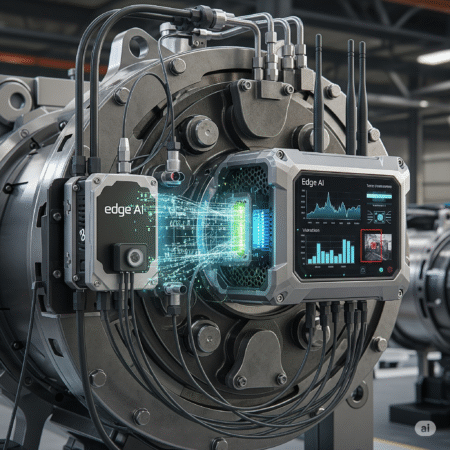

Step 1: Instrumentation & Data Collection

- Install IoT sensors (vibration, temp, current, pressure)

- Set up edge devices or gateways to collect data

Step 2: Build Data Pipeline

- Use tools like Apache Kafka or MQTT for real-time data streaming

- Store data in time-series databases like InfluxDB or AWS Timestream

Step 3: Data Preprocessing

- Filter noise

- Handle missing values

- Normalize the data

Step 4: Feature Engineering

- Extract statistical features (mean, RMS, kurtosis)

- Apply signal transformation (FFT, wavelet)

Step 5: Model Selection & Training

- Use supervised models (Random Forest, SVM) if labels are available

- Use unsupervised models (Autoencoders, K-Means) for anomaly detection

Step 6: Model Validation & Testing

- Cross-validate models to avoid overfitting

- Use test data to check real-world performance

Step 7: Deployment & Integration

- Deploy models on edge devices or cloud platforms

- Integrate with SCADA, CMMS, or DCS systems

Key Metrics to Monitor

| Metric | Description |

|---|---|

| Anomaly Detection Rate | % of anomalies correctly flagged |

| False Positive Rate | Alerts that don’t correspond to real issues |

| RUL Prediction Accuracy | Accuracy of Remaining Useful Life estimation |

| Model Drift Score | Indicates if the model needs retraining |

| Inference Latency | Time taken by the model to produce output |

Real-World Example: Predictive Maintenance in a Steel Plant

A leading steel manufacturer implemented an AI-based monitoring system for its rolling mills. Using sensor data (vibration, temperature, load), they built an anomaly detection system with an auto encoder neural network. Within 3 months:

- Unscheduled downtime reduced by 40%

- Maintenance cost dropped by 25%

- Asset availability improved by 18%

Challenges & Solutions

Poor Data Quality

Solution: Implement automated data validation at the edge.

Legacy Infrastructure

Solution: Use edge computing to enable AI without needing cloud dependencies.

Model Drift

Solution: Schedule periodic retraining using updated datasets.

Data Privacy & Security

Solution: Implement federated learning and end-to-end encryption.

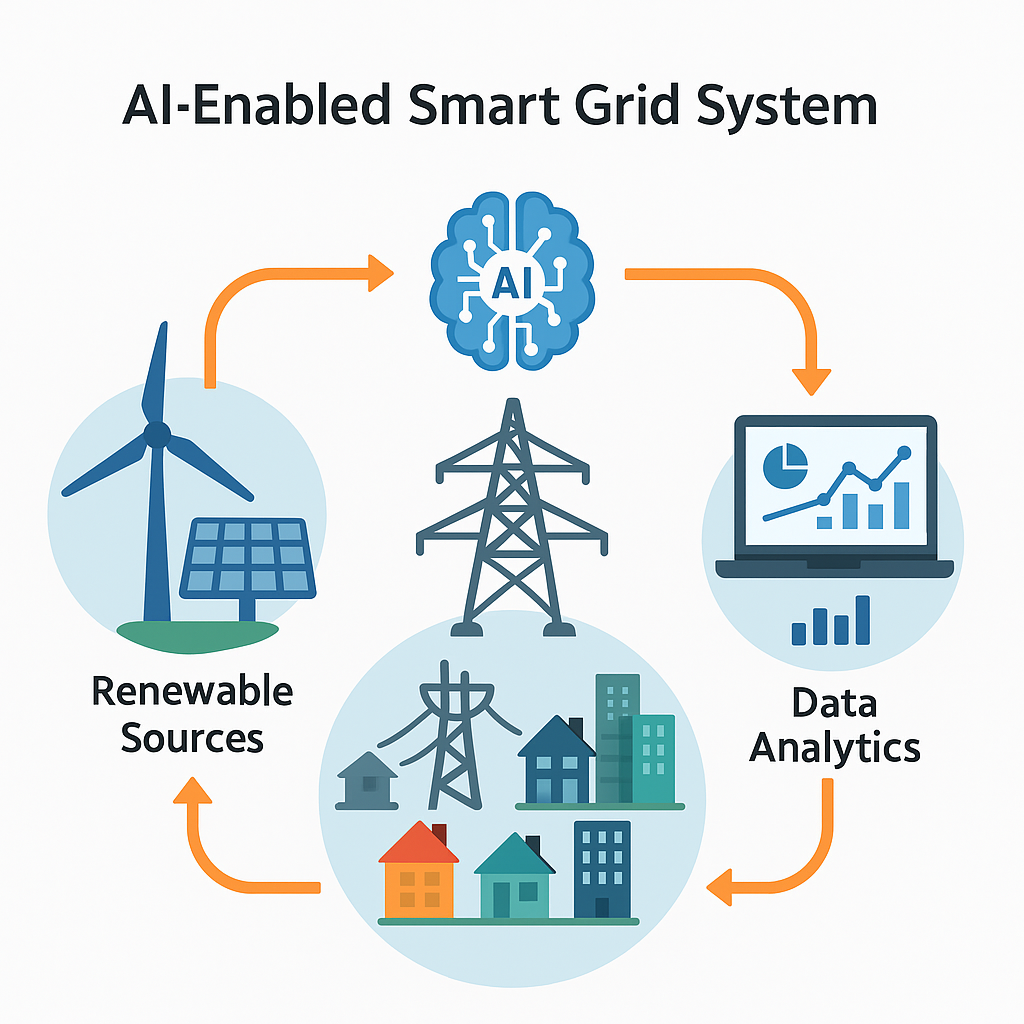

Future Outlook: What’s Next for AI in IIoT?

Federated Learning at the Edge

Allows collaborative model training without data sharing, preserving privacy.

Transfer Learning

Models trained on one machine type can be adapted to others with minimal data.

Explainable AI (XAI)

Improves transparency and trust in predictions made by AI systems.

Cloud-Edge Hybrid Deployment

Combines real-time local inference with centralized retraining for scalability.

Conclusion: Start Small, Scale Fast

AI-powered predictive analytics is transforming how industries approach maintenance and asset management. While the technology can seem complex, starting with a small pilot project and scaling based on ROI can yield significant benefits.

Whether you’re monitoring motors in a factory or pipelines in the field, the combination of AI and IIoT enables smarter decisions, safer operations, and a more efficient bottom line.

Take Action: Identify a critical machine, install basic sensors, collect data, and explore open-source AI models to get started. The future of industrial monitoring is predictive – and it’s already here.