Introduction

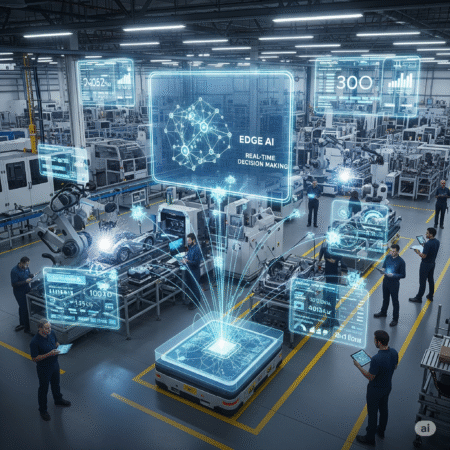

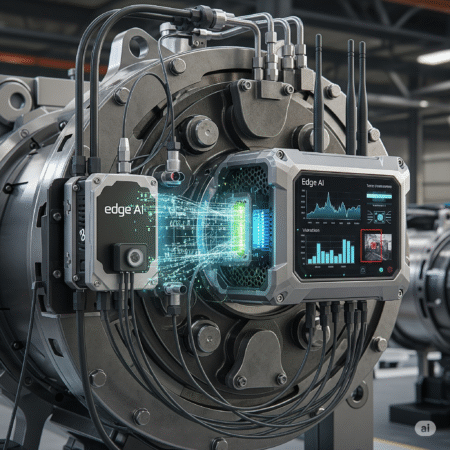

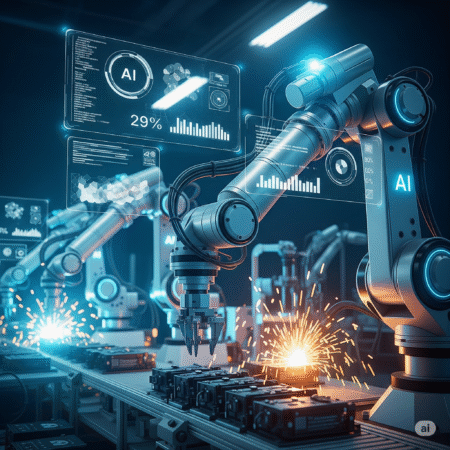

IoT for industrial automation Imagine running an industrial facility where machines make decisions in milliseconds without waiting for cloud responses. That’s the power of Edge AI in industrial automation. As industries shift toward real-time intelligence, edge computing embedded with AI is rapidly becoming the backbone of smarter, faster, and safer operations.

In this guide, we’ll break down how Edge AI works, why it matters, and how you can implement it effectively in your operations. Whether you’re a manufacturing engineer, automation lead, or a tech-savvy industrial professional, this article will give you actionable insights.

What is Edge AI?

Edge AI refers to deploying artificial intelligence models directly on edge devices, close to where data is generated – like machines, robots, and sensors. Unlike traditional AI systems that depend heavily on cloud processing, Edge AI eliminates latency by making decisions locally.

Edge AI vs. Cloud AI

| Feature | Edge AI | Cloud AI |

|---|---|---|

| Latency | Extremely low | High |

| Internet required | No | Yes |

| Privacy | More secure (local) | Risk of data exposure |

| Real-time control | Yes | Limited |

Benefits of Edge AI in Industrial Automation

Ultra-Low Latency

Edge AI enables real-time response, essential for processes like:

- Machine fault detection

- Quality inspection

- Emergency shutdowns

Reduced Bandwidth Use

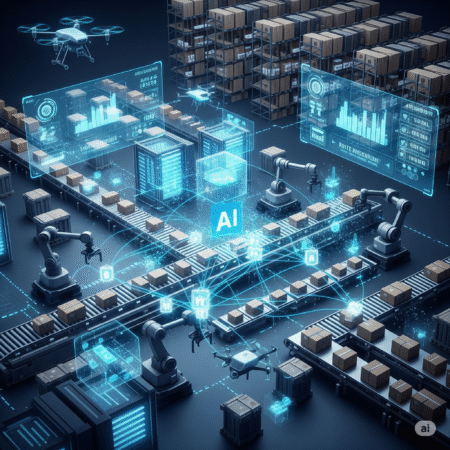

Data doesn’t need to be streamed to the cloud, saving bandwidth costs and improving network efficiency.

High Reliability

Operations continue even if cloud connectivity fails. This makes edge AI ideal for remote plants, oil rigs, or underground mines.

Enhanced Security

Keeping data on-site reduces the risk of cyberattacks or data leaks.

Top Use Cases in Industry

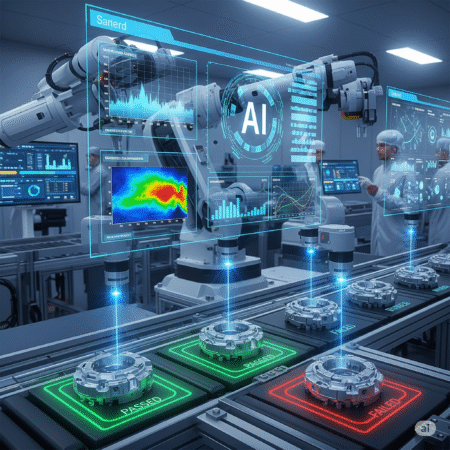

Real-Time Visual Inspection

AI models running on cameras or edge GPUs detect defects or irregularities in milliseconds.

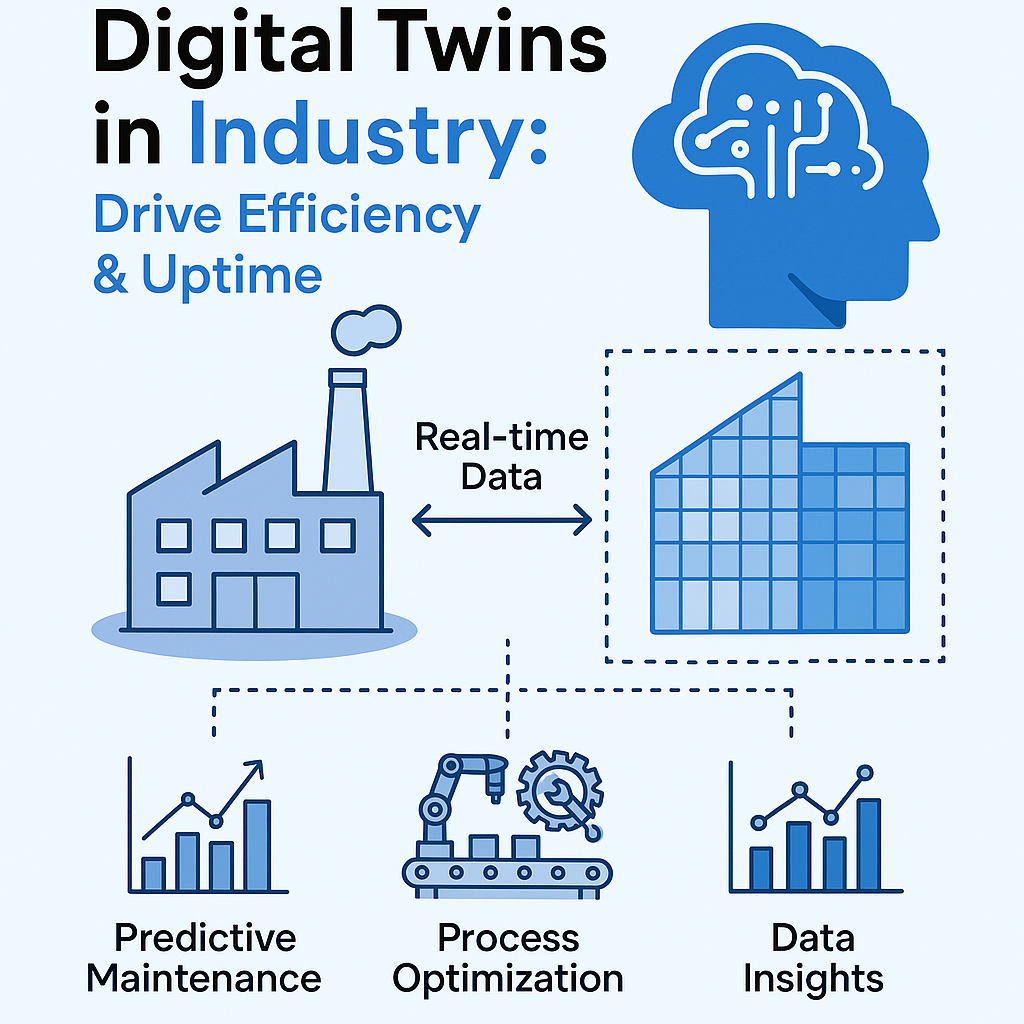

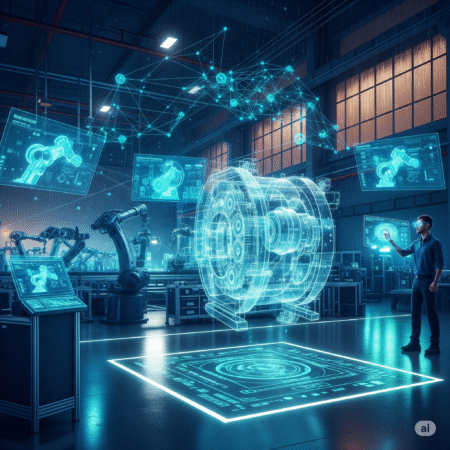

Predictive Maintenance

By analyzing sensor data in real-time, Edge AI can predict equipment failures before they happen.

Autonomous Guided Vehicles (AGVs)

AGVs use onboard AI for navigation, obstacle avoidance, and route optimization.

Worker Safety Monitoring

AI-powered edge systems can track worker movements, detect PPE compliance, and send alerts instantly.

How Edge AI Works

Hardware Components

- NVIDIA Jetson Nano / Xavier: Popular in factories for computer vision tasks

- Intel Movidius: Ideal for low-power vision inference

- Google Coral + Raspberry Pi: Cost-effective combo for prototyping

Software Tools

- TensorRT: Optimizes deep learning models for NVIDIA GPUs

- OpenVINO: Intel’s toolkit for AI model deployment

- Edge Impulse: Platform for building and deploying ML on embedded devices

Workflow

- Train AI model in the cloud

- Compress/optimize the model

- Deploy to edge device

- Integrate with existing control systems (e.g., SCADA, PLCs)

Implementation Roadmap

- Define Use Case Example: Detecting cracks in conveyor belts.

- Select Edge Hardware Based on power, memory, and environmental conditions.

- Data Collection Use sensors and cameras to gather real-world data.

- Model Training & Testing Train with labeled data and validate accuracy.

- Edge Deployment Use Docker or native frameworks to deploy models.

- Integration & Scaling Connect with existing SCADA, historian, or ERP systems.

Key Metrics to Monitor

- Inference time (ms)

- Model accuracy (%)

- Power consumption (W)

- Data throughput (MB/s)

- Failure prediction rate (%)

Challenges & Considerations

Limited Compute Resources

Edge devices have constraints; model compression and optimization are vital.

Model Updates

Pushing updates to distributed devices needs robust OTA (Over-The-Air) mechanisms.

Data Drift

Edge models need retraining when environmental or process variables shift significantly.

The Future of Edge AI in Industry

Federated Learning

Collaborative learning across devices without sharing raw data, improving model accuracy and privacy.

5G Integration

Combining 5G with Edge AI reduces latency further and supports more data-rich applications.

Edge-to-Cloud Sync

Hybrid systems will balance real-time processing at the edge with data aggregation in the cloud for deeper analytics.

Final Thoughts

Edge AI is transforming how industries operate. From cutting downtime to enhancing safety, the benefits are real and measurable. As edge devices become more powerful and affordable, expect broader adoption across sectors.

Whether you’re running a factory floor or managing an offshore platform, investing in Edge AI now could future-proof your operations.