- Introduction: What Makes Cognitive Digital Twins Revolutionary

- Understanding Digital Twin Architecture: Core Components and Functionality

- Physical Entity (The Real-World Object)

- Data Acquisition Layer (IoT and Sensor Integration)

- Communication Network (Data Pipeline)

- Data Storage and Management System

- Analytical Engine and Machine Learning Layer

- Visualization Interface (User Interaction Layer)

- Feedback Loop and Actuation

- Final Thoughts: The Architecture Must Be Scalable and Modular

- Digital Twin vs Traditional Simulation: What Sets Them Apart?

- Types of Digital Twins and Their Use Cases

- How to Implement a Digital Twin in Industrial Environments

- Step 1: Define the Business Objective

- Step 2: Identify the Physical Assets or Processes to Be Modeled

- Step 3: Collect and Connect the Data

- Step 4: Build the Virtual Model

- Step 5: Synchronize Real-Time Data

- Step 6: Test and Validate

- Bonus: Common Implementation Pitfalls (and How to Avoid Them)

- Final Thought

- Real-World Benefits of Industrial Digital Twin Technology

- Predictive Maintenance: Stop Failures Before They Happen

- Process Optimization: Get More from What You Already Have

- Faster Decision-Making with Real-Time Visibility

- Enhanced Safety and Remote Operations

- Shorter Time-to-Market for New Designs

- Sustainability and ESG Tracking

- Better Asset Lifecycle Management

- Quick Recap of Business Value:

- Final Thought

- The Future of Digital Twin Technology: Trends Shaping Industry 5.0

- Key Takeaways: Why This Matters for You

- Are You Ready for the Twin Revolution?

Introduction: What Makes Cognitive Digital Twins Revolutionary

Imagine being able to predict failures before they happen, optimize performance on the fly, and automate decision-making across your plant all without human intervention. That’s not science fiction. That’s the power of Cognitive Digital Twins, the next frontier in industrial transformation.

Here’s why they matter:

- Data is everywhere but insight is rare. Traditional systems collect siloed sensor data. What’s missing is an intelligent layer that learns from data trends, understands dependencies, and can forecast future behavior.

- Static twins are outdated. In traditional “digital twin” setups, your virtual model mimics current operation but doesn’t learn. A Cognitive Digital Twin goes further: it adapts over time, learns from feedback loops, and evolves alongside your equipment.

- Fast decision-making is non-negotiable. Global enterprises lose thousands per minute when assets fail. Cognitive twins powered by AI and graph learning detect anomalies, recommend corrective actions, and in some cases, execute them automatically.

- Scalability that grows with your system. Whether you have 10 or 10,000 assets, Cognitive Digital Twins can scale within a cloud-edge architecture so every pump, turbine, or line becomes smart.

- Real ROI, not just buzz. Leaders implementing this technology report:

- 30–40% reduction in unplanned downtime

- 10–20% energy savings thanks to real-time optimization

- Faster onboarding via virtual simulations

So if you’re an industrial engineer, plant manager, or digital transformation leader and you type in keywords like “cognitive digital twin manufacturing”, “graph learning for predictive maintenance”, or “virtual sensors for smart factories” you’re looking for deep, actionable solutions. Not theory.

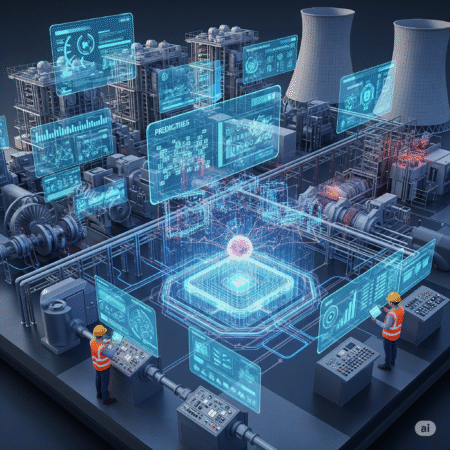

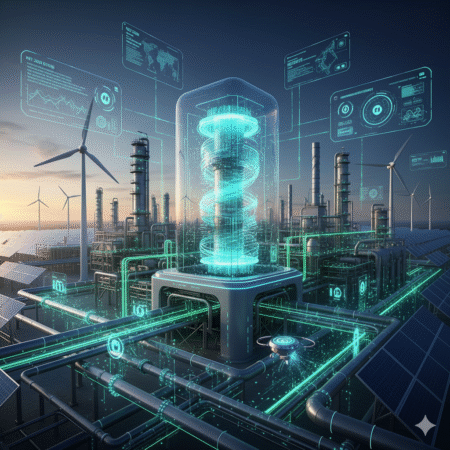

Understanding Digital Twin Architecture: Core Components and Functionality

To unlock the real value of a Digital Twin, we need to dive deep into its architecture – the core components that bring it to life and how they interact to mirror, analyze, and optimize physical assets in real time.

Let’s break it down.

Physical Entity (The Real-World Object)

At the heart of any Digital Twin system lies the physical asset – a machine, device, production line, or even an entire facility. This is the object that the digital twin shadows. Sensors and IoT devices are embedded within or around the asset to constantly capture real-world data such as temperature, pressure, vibration, and performance metrics.

Think of this as the “organism” that the digital twin is constantly watching and learning from.

Data Acquisition Layer (IoT and Sensor Integration)

This is where the magic of data collection happens. Smart sensors, RFID tags, edge devices, and data loggers serve as the frontlines – capturing, transmitting, and preprocessing raw data from the physical entity.

Here’s why it matters:

- Without reliable sensors, your digital twin is blind.

- Real-time responsiveness hinges on the quality, frequency, and granularity of this sensor data.

In modern industrial setups, edge computing often filters or compresses data before sending it upstream – reducing latency and improving system performance.

Communication Network (Data Pipeline)

All that sensor data needs to go somewhere. That’s where secure and high-speed network infrastructure comes in. From 5G, LoRaWAN, MQTT, OPC UA, to industrial Ethernet – this layer ensures real-time, two-way data flow between the physical and digital worlds.

Bonus tip: Many enterprises are now using hybrid networks to combine wired stability with wireless scalability.

Data Storage and Management System

Once data hits the cloud or edge platform, it must be:

- Structured

- Cleaned

- Labeled

- Stored

High-performance databases (SQL, NoSQL), cloud storage (AWS S3, Azure Blob), and time-series databases (InfluxDB) are typically used to manage massive volumes of data.

Security is paramount here. Compliance with GDPR, ISO 27001, and NIST standards ensures your digital twin system is resilient and secure from cyber threats.

Analytical Engine and Machine Learning Layer

This is the brain of the digital twin. It includes:

- Simulation Models

- Predictive Algorithms

- AI/ML Models

- Data Analytics Dashboards

These models are trained to recognize patterns, predict equipment failures, optimize operations, and even recommend corrective actions.

For example, in a gas turbine digital twin, ML algorithms can detect combustion instabilities before they result in catastrophic damage.

This layer turns raw data into actionable insights.

Visualization Interface (User Interaction Layer)

The final piece? A powerful, intuitive dashboard that allows engineers, operators, and decision-makers to interact with the digital twin. Using 2D/3D interfaces, AR/VR, and immersive visualizations, users can:

- Monitor asset performance in real-time

- Simulate “what-if” scenarios

- Receive alerts and insights

Imagine walking through your offshore rig’s digital twin using AR glasses and spotting anomalies without setting foot on-site.

Feedback Loop and Actuation

Here’s where the digital twin goes beyond monitoring – it starts controlling.

With the right setup, a digital twin can automatically send commands back to the physical asset to:

- Adjust temperature set points

- Trigger maintenance actions

- Shut down operations in case of anomalies

This is the closed-loop system that drives autonomy and optimization.

Final Thoughts: The Architecture Must Be Scalable and Modular

Digital Twin systems aren’t one-size-fits-all. As your assets evolve and your data grows, your architecture must adapt.

That’s why leaders like Siemens, GE, and IBM build modular, plug-and-play architectures – allowing them to scale digital twin solutions across thousands of assets.

Digital Twin vs Traditional Simulation: What Sets Them Apart?

You’ve probably heard people confuse digital twins with simulations. And while they do share some DNA, make no mistake they are not the same thing.

Let’s break down the key differences so you can understand why digital twins are a game changer, especially for industrial environments.

Static vs Dynamic

Traditional simulations are static. You run them once (or occasionally), based on predefined parameters. They give you a snapshot in time – valuable, but limited.

Digital twins, on the other hand, are dynamic. They’re alive. They continuously receive real-time data from the physical asset and update their behavior accordingly.

It’s like comparing a photograph (simulation) to a live video feed (digital twin).

Frequency of Use

- Simulation is used for one-off or scheduled analysis – like during design phases or troubleshooting.

- Digital Twin operates 24/7. It’s always watching, learning, predicting, and optimizing.

In industries like energy, manufacturing, and aerospace, this always-on monitoring is crucial for avoiding downtime and increasing efficiency.

Data Connectivity

Simulations often use historical or hypothetical data.

Digital twins are connected to the real-time sensor feeds of the physical asset. This allows them to model actual behavior as it happens, and even adjust predictions based on new input.

That’s why digital twins are so powerful in predictive maintenance – they evolve with your asset.

Integration with Control Systems

A traditional simulation is passive. You analyze it, make a decision, and apply the outcome manually.

Digital twins go a step further. They can automatically control or recommend actions to be taken in the physical world via closed-loop systems.

This is what makes digital twins a foundational piece of Industry 4.0 they enable autonomous decision-making based on real data.

Scope and Scalability

Simulations are usually built for specific, isolated problems. You might run a fluid dynamic simulation on one pipeline or a stress test on a single beam.

Digital twins can scale to model entire systems – from a single compressor to a full refinery, and even across multiple facilities.

Lifecycle Coverage

Simulations are mostly used in the design or testing phase. Once the product is built, simulations are rarely revisited.

Digital twins cover the entire asset lifecycle:

- Design

- Commissioning

- Operations

- Maintenance

- Decommissioning

This long-term engagement drives better asset performance, improved ROI, and deep insights over time.

Quick Comparison Table

| Feature | Traditional Simulation | Digital Twin |

|---|---|---|

| Data Source | Historical or static input | Real-time data from sensors |

| Usage Frequency | Occasional | Continuous, 24/7 |

| Integration with Assets | Isolated | Fully integrated |

| Decision-Making | Manual | Automated or semi-automated |

| Lifecycle Coverage | Design/Test | Full asset lifecycle |

| Scalability | Limited | Highly scalable across systems |

Bottom Line

Simulations are great — but they’re only part of the story. If you want to optimize, predict, and automate in real time, you need digital twins. They bring a living, breathing dimension to your operational intelligence one that evolves with your assets.

Types of Digital Twins and Their Use Cases

Digital twins aren’t one-size-fits-all. In fact, there are different types designed for different layers of complexity from individual parts to entire ecosystems. If you pick the wrong type, you’re either wasting money or missing out on potential insights.

Let’s break it down.

Component Twins

This is the simplest form of a digital twin. It represents a single part like a valve, a pump, or a motor bearing.

Use Case:

In predictive maintenance, a component twin can monitor vibration, temperature, and wear of a pump bearing. If the temperature rises beyond a safe threshold, the system can alert maintenance teams before a failure occurs.

Ideal for: OEMs, equipment manufacturers, maintenance teams

Asset Twins

Think of this as a level up. An asset twin models the entire physical asset, made up of multiple components – for example, an entire compressor, turbine, or robotic arm.

Use Case:

In oil & gas, a compressor twin monitors not just internal parts but the interactions between them – pressure differentials, gas flow rates, energy consumption. It allows optimization in real-time based on actual field conditions.

Ideal for: Industrial facilities, energy plants, utilities

System or Unit Twins

A system twin combines multiple assets working together in a process. It models how those assets interact dynamically – think of an entire production line, HVAC system, or water treatment unit.

Use Case:

In manufacturing, a system twin can simulate an entire assembly line to detect bottlenecks, balance workloads, or test changes before deploying them physically.

Ideal for: Manufacturing plants, warehouses, smart buildings

Process Twins

This is where things get really powerful. A process twin models an entire operational workflow – from raw input to final output, across machines, people, and systems.

Use Case:

In chemical processing, a process twin can simulate how different raw materials behave under varying temperatures and pressures. This helps identify the most energy-efficient and safe operating conditions in real time.

Ideal for: Chemical, pharmaceutical, oil & gas refining, power plants

Network or Ecosystem Twins

This is the highest level of digital twin maturity. It models multiple interconnected systems like an entire factory, city infrastructure, or supply chain network.

Use Case:

In logistics, an ecosystem twin can track deliveries, warehouse inventories, vehicle telemetry, and weather data all at once to optimize the supply chain on the fly.

Ideal for: Smart cities, large industrial conglomerates, logistics networks

Which Type Do You Need?

Let’s make it practical. Here’s how to choose:

- Are you monitoring a single device or sensor? ➜ Component Twin

- A full machine or instrument? ➜ Asset Twin

- A set of machines working together? ➜ System Twin

- A full process from start to finish? ➜ Process Twin

- A complex, connected operation across regions or business units? ➜ Ecosystem Twin

Final Thought

Choosing the right type of digital twin isn’t just technical – it’s strategic. Start small (component or asset), prove ROI, then scale upward. Each level gives you greater insight, control, and automation.

How to Implement a Digital Twin in Industrial Environments

Digital twin technology sounds powerful and it is but let’s make it realistic and actionable.

Whether you’re in oil & gas, manufacturing, or power, here’s a step-by-step framework for deploying a digital twin that delivers actual ROI.

Step 1: Define the Business Objective

Don’t start with the tech.

Start with the problem you’re solving.

Ask:

- Are you aiming to reduce downtime?

- Do you want real-time performance monitoring?

- Are you trying to optimize energy usage?

- Do you need simulation before physical changes?

Your business goal will shape the type of twin, the data you need, and the architecture required.

Step 2: Identify the Physical Assets or Processes to Be Modeled

You don’t need to model your entire facility on day one.

Start with:

- A critical asset (e.g., turbine, pump, heat exchanger)

- A process bottleneck

- A high-maintenance system that often fails

Tip: Pick a use case where success will demonstrate clear ROI and help get buy-in for future scaling.

Step 3: Collect and Connect the Data

Digital twins are only as smart as the data that feeds them.

You’ll need:

- Sensor data (temperature, pressure, vibration, flow)

- Historical data (maintenance records, failure logs)

- Design specs (P&IDs, datasheets, CAD models)

- Real-time streams via IoT gateways or SCADA integration

Tools you might use:

AWS IoT, Azure Digital Twins, PTC ThingWorx, Siemens MindSphere

Step 4: Build the Virtual Model

Now, model the physical twin using the data you’ve gathered.

This includes:

- 3D CAD or BIM models for visualization

- Physics-based or ML-based simulation models

- Rule-based logic for behavior prediction

Advanced: Add AI/ML for anomaly detection and predictive maintenance.

Visualization Layer: Use dashboards (e.g., Grafana, Power BI, AVEVA Insight) to make the twin actionable for operators and decision-makers.

Step 5: Synchronize Real-Time Data

The heart of a digital twin is its real-time feedback loop. Your physical asset and digital model must constantly sync.

This enables:

- Live status monitoring

- Early warning alerts

- Real-time simulations and “what-if” analysis

Don’t skip cybersecurity. Secure your data streams using VPN, TLS, and endpoint protection especially for OT/IT convergence.

Step 6: Test and Validate

Before going live, test the twin against real scenarios:

- Does it accurately reflect physical conditions?

- Can it predict failures or suggest optimizations?

- Are operators and engineers finding it useful?

Run simulations, conduct A/B tests, and verify accuracy.

Scale and Integrate

Once proven on one asset or process, scale it:

- Extend to multiple machines or units

- Integrate with MES/ERP/CMMS systems

- Automate decision-making with AI models

Pro Tip: Use modular architecture so you can scale without rebuilding everything.

Bonus: Common Implementation Pitfalls (and How to Avoid Them)

| Mistake | What to Do Instead |

|---|---|

| Starting too big | Start small and scale with proven ROI |

| Poor data quality | Prioritize sensor calibration and filtering |

| Over-reliance on vendors | Build in-house capability for sustainability |

| No end-user training | Involve operators from the start |

| Ignoring cybersecurity | Treat it as critical infrastructure |

Final Thought

Implementing a digital twin is a journey, not a switch-flip. But done right, it becomes your control tower delivering insights, predictions, and optimizations that were never possible before.

Real-World Benefits of Industrial Digital Twin Technology

Digital twins are more than a buzzword. They deliver concrete benefits that impact the bottom line, enhance operations, and give companies a real competitive edge.

Here’s a deep dive into the key advantages with real examples from industry.

Predictive Maintenance: Stop Failures Before They Happen

Traditional maintenance = reactive.

Digital twin maintenance = predictive and proactive.

With real-time data and simulation, digital twins can:

- Detect abnormal patterns

- Predict part failure timelines

- Schedule maintenance before breakdowns occur

Example: A petrochemical plant using a digital twin of a rotating compressor reduced unplanned downtime by 30% in 6 months.

Value Delivered:

- Fewer emergency shutdowns

- Lower maintenance costs

- Increased equipment life

Process Optimization: Get More from What You Already Have

Digital twins enable live “what-if” simulations to:

- Test new configurations

- Optimize energy usage

- Identify inefficiencies in processes

Example: A steel manufacturer used a digital twin of its rolling mill to adjust temperature profiles and saved $1.2M annually in energy costs.

Value Delivered:

- Higher throughput

- Reduced energy consumption

- Lower operational waste

Faster Decision-Making with Real-Time Visibility

Executives and operators no longer have to wait for reports.

With digital twins, they can:

- Monitor KPIs live

- Simulate consequences of decisions instantly

- Make data-backed decisions faster than competitors

Example: A food processing plant used digital twin dashboards to make weekly planning decisions in minutes instead of hours.

Value Delivered:

- Speed and agility

- Better risk management

- Improved productivity

Enhanced Safety and Remote Operations

Operating in hazardous areas? No problem.

Digital twins:

- Allow remote monitoring of assets in dangerous environments

- Simulate hazardous events (fires, leaks) for emergency planning

- Reduce human exposure on-site

Example: Offshore oil platforms use digital twins to remotely monitor valve integrity and corrosion levels, reducing the need for manual inspection dives.

Value Delivered:

- Safer work environments

- Reduced insurance liability

- Remote site control and diagnostics

Shorter Time-to-Market for New Designs

Before building physical prototypes, companies can:

- Run digital simulations

- Optimize product performance

- Identify design flaws early

Example: An aerospace company used a digital twin to test aerodynamic properties before wind tunnel testing, shaving 4 months off development time.

Value Delivered:

- Faster innovation cycles

- Cost savings in R&D

- Competitive advantage in product launch

Sustainability and ESG Tracking

With increasing pressure to reduce environmental impact, digital twins help:

- Monitor energy and water usage

- Predict emissions

- Simulate greener operations before implementing them

Example: A smart building system using digital twin tech achieved a 15% reduction in HVAC energy use by continuously adjusting ventilation based on occupancy data.

Value Delivered:

- Lower carbon footprint

- Regulatory compliance

- ESG goal achievement

Better Asset Lifecycle Management

From procurement to decommissioning, digital twins help manage every stage of an asset’s life:

- Forecast wear and replacement needs

- Optimize performance during peak usage

- Plan end-of-life strategies with minimal disruption

Example: A utility company tracked transformer aging with digital twins and prevented 3 major outages during peak demand months.

Value Delivered:

- Extended asset lifespan

- Reduced lifecycle costs

- Smoother operations

Quick Recap of Business Value:

| Benefit | ROI Impact |

|---|---|

| Predictive Maintenance | ↓ Downtime, ↓ Repair Costs |

| Process Optimization | ↑ Efficiency, ↓ Energy Costs |

| Real-Time Visibility | ↑ Speed of Decision-Making |

| Safety & Remote Ops | ↓ Site Risks, ↓ OPEX |

| Faster Product Development | ↑ Innovation, ↓ Time-to-Market |

| Sustainability Improvements | ↓ Emissions, ↑ ESG Score |

| Lifecycle Management | ↑ Asset Longevity, ↓ CAPEX & OPEX |

Final Thought

If your competitors are using digital twins and you’re not you’re already behind.

This tech is transforming operations across industries, and it’s only accelerating. From real-time decisions to long-term strategic planning, digital twins give your company superpowers to act smarter, faster, and more efficiently.

The Future of Digital Twin Technology: Trends Shaping Industry 5.0

Digital twins aren’t standing still. As industries move toward Industry 5.0, this technology is evolving into a core pillar of smart, resilient, and human-centric operations.

Let’s break down the top future trends so your readers stay ahead of the curve.

AI-Augmented Digital Twins: Smarter Than Ever

Traditional digital twins replicate behavior.

AI-powered twins predict, adapt, and learn in real-time.

- Self-learning systems: Continuously improve accuracy using historical + real-time data.

- Cognitive twins: Incorporate NLP, computer vision, and reasoning to replicate human-like decision-making.

- Autonomous operations: AI-driven twins can initiate actions without human input, e.g., shutdowns, rerouting systems, etc.

Think of it as: From passive replica → to intelligent co-pilot.

Federated and Networked Digital Twins

As companies digitize entire ecosystems, the future lies in connected twins:

- Digital twins for individual assets → link into system-wide models

- Enables cross-site optimization, centralized visibility, and collaborative forecasting

Example: A multinational energy firm connects digital twins of turbines, pipelines, and substations across regions optimizing power flow and grid stability holistically.

Digital Twins + Simulation at Scale

Simulation will go from “one-off experiments” to continuous forecasting engines.

- Run millions of “what-if” scenarios

- Predict impact of regulation changes, climate, or demand spikes

- Accelerate planning with instant feedback loops

Combined with cloud computing and edge AI, simulation at scale will become the new operational standard.

Integration with Blockchain for Data Trust

As digital twins share real-time data across teams, trust becomes essential.

Enter blockchain:

- Immutable records of asset data and changes

- Transparent maintenance history

- Enhanced data auditability for compliance (ISO, ESG, etc.)

Especially valuable in industries with strict safety standards: aerospace, pharmaceuticals, nuclear.

Sustainability Twins: Measuring Green KPIs

Regulations and investors are demanding sustainability metrics.

Digital twins will be tasked to:

- Track Scope 1, 2, and 3 emissions

- Simulate greener alternatives

- Guide ESG reporting with real-time environmental KPIs

Example: A packaging company uses a digital twin to redesign its process and reduce plastic waste by 40%.

Sustainability won’t be optional. Digital twins will help make it profitable.

Human-in-the-Loop Digital Twins

Industry 5.0 emphasizes human-machine collaboration.

- Digital twins will be paired with augmented reality (AR), letting field technicians interact with virtual layers

- VR-based simulations for training and safety

- Decision-support dashboards tailored for human operators

Example: A maintenance engineer in a chemical plant uses AR glasses to “see” the digital twin’s health overlay on live equipment.

Cybersecurity-First Architecture

With digital twins connected to OT/IT systems and cloud platforms, security is no longer optional.

Expect to see:

- End-to-end encryption for data streams

- Zero trust architecture for access control

- Real-time anomaly detection in twin networks

Bonus trend: AI-based cybersecurity twins that simulate potential cyberattacks and help prepare defenses in advance.

Key Takeaways: Why This Matters for You

| Future Trend | Strategic Advantage |

|---|---|

| AI-Augmented Twins | Autonomy, predictive precision |

| Federated Networks | Enterprise-wide visibility, synergy |

| Simulation at Scale | Fast adaptation, futureproofing |

| Blockchain Integration | Trusted data, regulatory readiness |

| Sustainability KPIs | Compliance, investor appeal, green innovation |

| Human-Machine Collaboration | Empowered workforce, safer operations |

| Cybersecurity by Design | Resilience, business continuity |

The winners in Industry 5.0 won’t just adopt digital twins they’ll evolve them.

Are You Ready for the Twin Revolution?

If you haven’t already started integrating digital twin technology into your operations, now’s the time. Start small. Focus on high-impact assets. Learn. Iterate. Scale.

The future belongs to organizations that act, adapt, and evolve and digital twins are your fastest route to that future.

Stay tuned on EngineerDaily.News for more in-depth guides on AI, automation, cybersecurity, and smart industrial innovation.