- Introduction

- The Real Problem with Traditional Supply Chains

- How AI Transforms Supply Chain Management

- Real-Time Visibility Through Data Analytics

- AI in Forecasting, Planning, and Inventory Management

- Case Studies: Industry Success Stories

- Challenges in Implementation and Solutions

- Future Trends in AI-Driven Supply Chains

- Conclusion: Don’t Get Left Behind

- FAQs

Introduction

Global supply chains are no longer a linear network—they’re complex, interdependent systems. One delay in China can ripple through to production in Mexico and fulfillment in Germany.

AI offers a real solution—not just incremental improvements, but transformational change.

The Real Problem with Traditional Supply Chains

- Manual planning processes

- Limited real-time visibility

- Reacting instead of predicting

- Overstocks or stockouts

- Siloed data across departments

These issues lead to increased costs, reduced customer satisfaction, and missed opportunities.

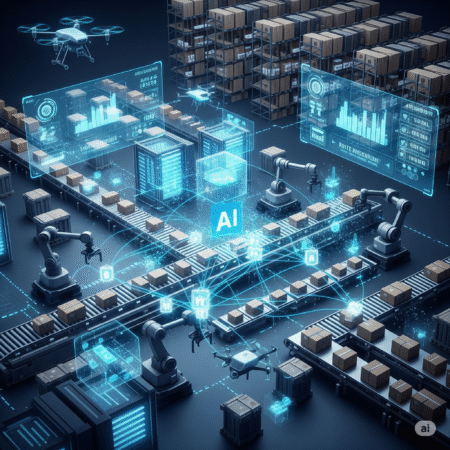

How AI Transforms Supply Chain Management

Artificial Intelligence improves supply chains by:

- Automating routine decisions

- Predicting demand with high accuracy

- Adjusting supply plans in real time

- Detecting anomalies in transportation or inventory levels

By integrating machine learning algorithms with historical and real-time data, AI provides intelligent decision support across procurement, production, and logistics.

Real-Time Visibility Through Data Analytics

Supply chain leaders today crave visibility—AI delivers it through:

- IoT devices tracking goods in transit

- Edge computing for local decision-making

- Dashboards with actionable KPIs

- Integration across ERP, CRM, and warehouse systems

Real-world Impact: A 2024 McKinsey study shows AI-enabled visibility reduced shipping delays by up to 40%.

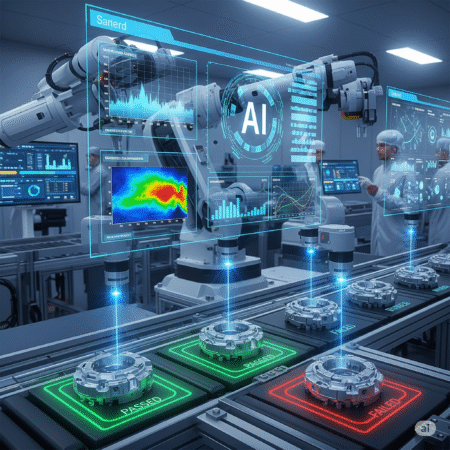

AI in Forecasting, Planning, and Inventory Management

AI systems like deep learning models are now used for:

- Demand Forecasting – by analyzing seasonality, trends, and macro events

- Inventory Optimization – balancing overstock vs. understock using predictive analytics

- Production Planning – adjusting schedules in real time based on demand/supply shifts

- Route Optimization – reducing delivery costs by up to 25% using AI-powered logistics tools

Case Studies: Industry Success Stories

Walmart

Leveraging AI for supply chain forecasting led to a 15% reduction in overstocking and better freshness in perishables.

Unilever

Uses AI-driven demand sensing to reduce inventory levels while increasing on-shelf availability.

DHL

Applied machine learning to predict shipment delays—improving delivery accuracy by over 80%.

Challenges in Implementation and Solutions

| Challenge | AI-Driven Solution |

|---|---|

| Data silos | Unified data lakes via cloud integration |

| Change resistance | Training + cross-functional workshops |

| Cost of AI tools | Cloud-based SaaS AI tools reduce CapEx |

| Lack of in-house expertise | Partner with AI consultancies |

Tip: Start with one area like forecasting before scaling across your supply chain.

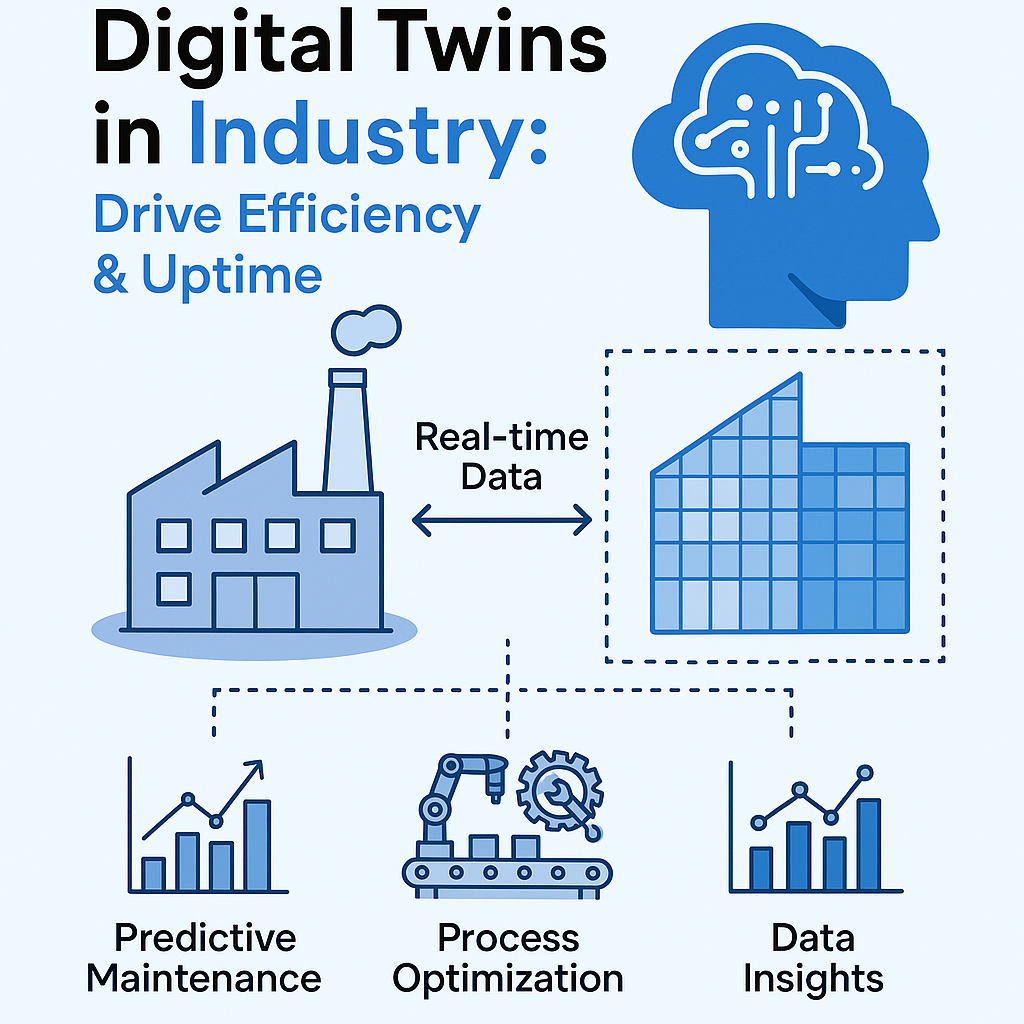

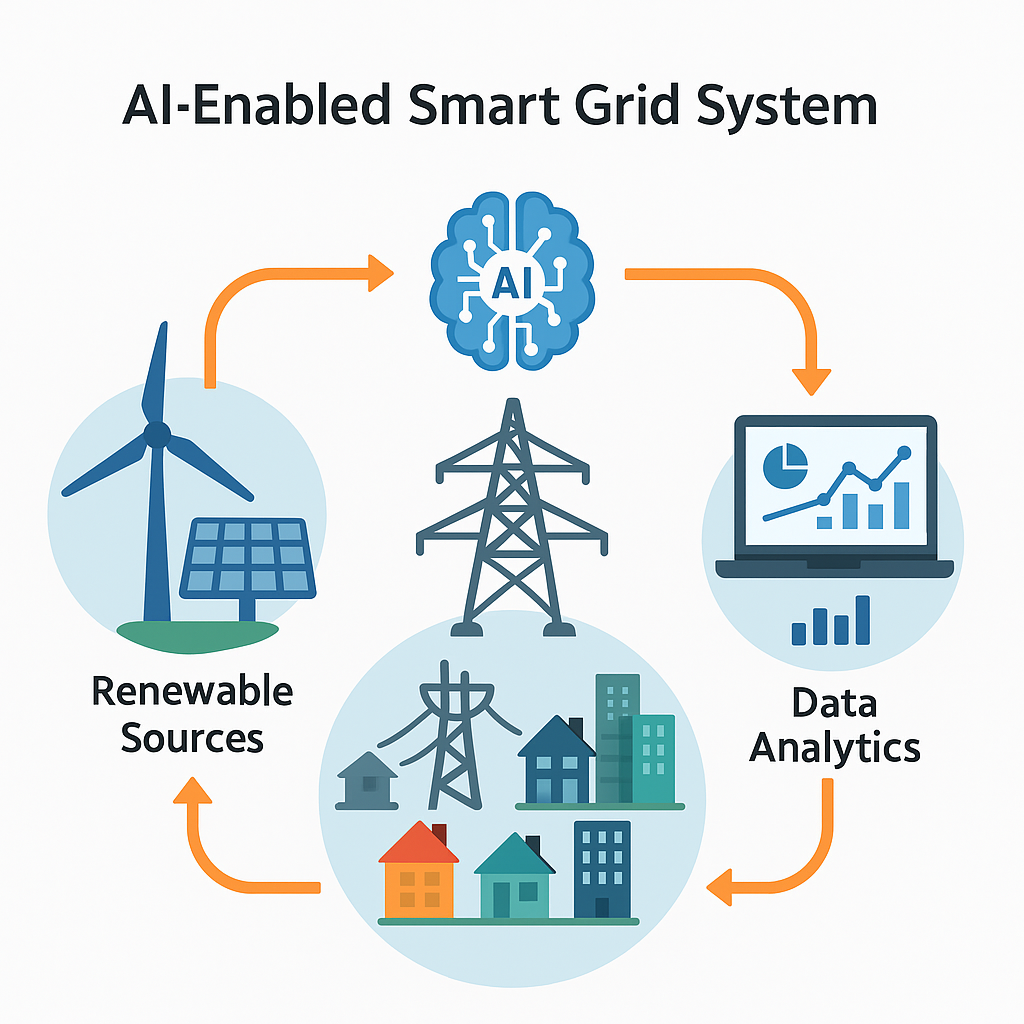

Future Trends in AI-Driven Supply Chains

- Digital Twins of entire supply networks

- AI + Blockchain for traceability

- Generative AI for smart procurement negotiation

- Autonomous warehousing with AI robots

By 2030, over 80% of supply chains will be AI-enhanced according to Gartner.

Conclusion: Don’t Get Left Behind

AI isn’t optional anymore—it’s the foundation for modern supply chains. Whether you’re running a mid-sized operation or a global enterprise, the time to act is now.

Want to explore AI tools for your supply chain?

Subscribe to EngineerDaily.News and stay ahead with expert insights and weekly case studies!

FAQs

Q1: Is AI expensive to implement in supply chains?

Not necessarily. Cloud-based AI tools have reduced upfront costs and many platforms offer subscription models.

Q2: Can AI work with my existing ERP system?

Yes, many AI solutions offer API integrations with popular ERP tools like SAP, Oracle, or Microsoft Dynamics.

Q3: What’s the fastest way to start?

Start with AI-powered demand forecasting—this offers the quickest ROI and is the least complex to implement.